Perfection in the Basics.

The Peddinghaus Advantage CNC Beam Drill Line is a machine designed to apply high speed steel (morse taper) drill tooling to the production of structural steel members. From square/rectangular tubing to angle iron, the Advantage will quickly and accurately produce 50-75 tons per week of processed profiles (this can fluctuate based on section size and complexity of operations).

Why Peddinghaus Advantage CNC Beam Drill Line?

- CNC beam drill line for drilling, scribing, roller measurement, and hard stamping

- Processes an average of 75 tons of steel per week with the most efficient drilling, scribing, and stamping operations

- Utilizes completely electronic spindle motion

- The Advantage is the ultimate combination of agility and strength

High Speed Drilling

Powered by 13.5 HP (10 kW) spindle motors, the Advantage is outfitted with 3 drill spindles. This powerful drilling technology allows for maximized operating time and drill hole quality.

SignoScript Scribing

The SignoScript layout marking attachment eliminates human error in manual layout methods. Complete information is maintained throughout blasting, galvanizing and painting processes.

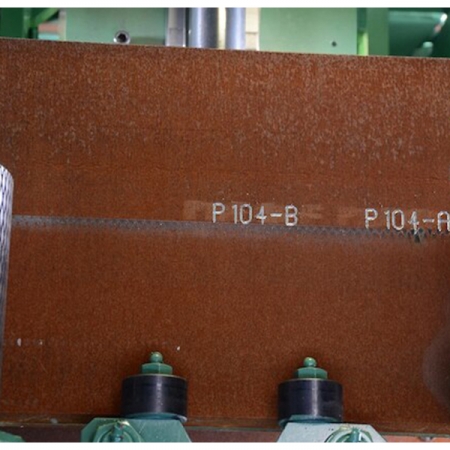

SignoMat Part Stamping

An optional part stamping system maximizes part numbering efficiency. SignoMat technology stamps up to 36 characters or numbers at a rate of one character per second.

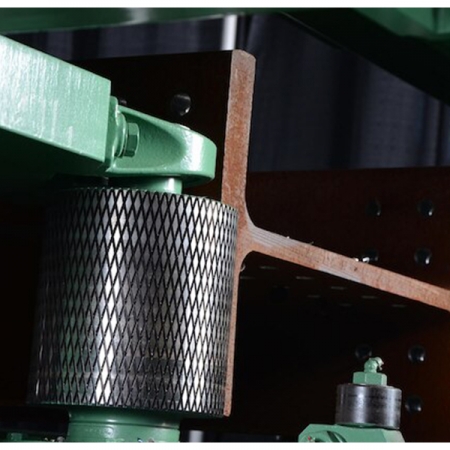

Nonstop Throughput with Roller Feed Measurement

Peddinghaus’ Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.

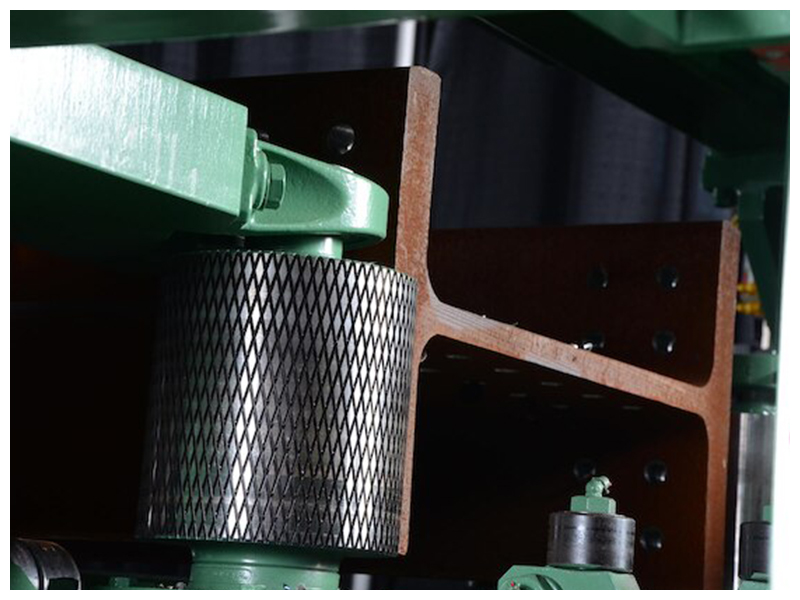

Sturdy Drill Clamping to Eliminate Vibration

The Advantage employs a series of support clamps in order to achieve optimum rigidity of the workpiece through the machine. Tool life is best sustained with the least amount of vibration possible.

Break-Through Detection Technology for Faster Drilling

Peddinghaus engineers pioneered a system that instantaneously senses material break-through notifying the machine of the moment a hole is completed and immediately advancing to the next hole in a pattern. Break-through detection technology is designed to increase the amount of time that your drill is actually drilling material.

Band Saw Integration

The Advantage drill line with its powerful material handling support, meticulous measurement capabilities and high speed designs are ideal for tandem installations with any of Peddinghaus’ automatic sawing systems.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.