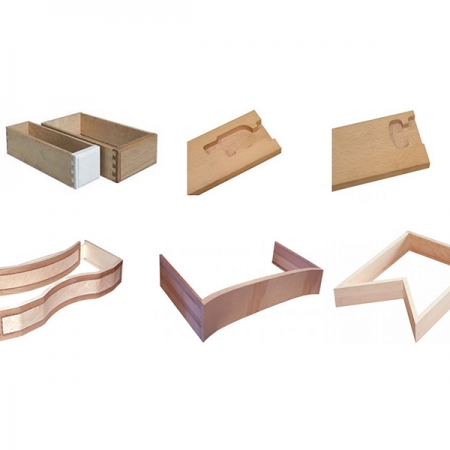

High speed automatic dovetail machine for traditional dovetail joints, French dovetail joints, box dovetail joints.

The Omec F11TS CNC Dovetailer is a two-axis automatic dovetail machine with computer numerical control which is designed to produce a wide range of dovetail joints including standard, French, and box dovetails for drawers and furniture elements. The machine is extremely flexible and capable of performing ten different types of dovetail indents. Model F11TS is equipped with a high RPM spindle and a mill cutter that allow the production of indents of different heights. The machine is designed to cut single male or female workpieces or both simultaneously. Pieces can be clamped and released in manual mode by means of pneumatic valves. The user-friendly touchscreen CNC controls allow for the utmost flexibility in the pitch and type of the dovetail joint without limitations. The graphic display allows you to quicky recall programs resulting in greater output. Additionally, the F11TS can pre-score the material to ensure optimum finish in the drawer pieces. As it optimizes the cutting function to the size of the workpiece you are guaranteed maximum efficiency resulting in greater output.

Why Omec F11TS CNC Dovetailer

- User-friendly touch screen interface with 7” graphical display

- Production capacity up to 120 dovetail drawer boxes per hour

- Optimized cutting cycle according to the drawer height being machined

- A wide range of dovetail programs come standard with the machine

- Fixed and variable dovetail pitch programs

- 18000 RPM spindle and high precision spiral dovetail cutters produce optimum dovetailing results

- Type of indents

- Pitch of indents and the offset

- Number of indents

- Depth of indents

- Dimensions of the pieces

- Cutting speed and tool feeding

- Compensation of the tool radius variation

- All the adjustments can be easily carried out following the software instructions of the machine displayed on the monitor.

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.