The Ultimate Bandsaw for ALL Your Fabrication Requirements.

The Ocean Machinery Terminator 18/42 Dual Column Double Miter Bandsaw is the largest saw from Ocean Machinery and is specifically designed for structural steel fabricators to handle the largest beams and profiles, and the heaviest sections that structural steel fabricators cut on a daily basis. The ability to miter cut both directions significantly reduces the material handling time, further improving your profitability.

Why Ocean Machinery Terminator 18/42 Dual Column Double Miter Bandsaw?

- Laser-guide to assist lining up the material

- Digital feedback display of miter angle and blade speed

- Dual vices to clamp the material on each side of the blade ensuring sawing accuracy and improved blade life

- Overhead clamp to support bundle cutting, increasing rigidity and improving cutting accuracy

KEY FEATURES

HUGE Sawing Capacity

- The Ocean Terminator can handle the largest steel profiles.

Miter Cuts Both Ways

- The ability to miter cut in both directions significantly reduces material handling time and reduces your cost per cut.

- The Terminator DCM-18/42 dual-column band saw miters up to 45 degrees left and 60 degrees right.

Fast Accurate Positioning

- The laser guide allows the operator to quickly line up the saw cut-line at the precise position, significantly reducing positioning time.

Faster Sawing

- A powerful 10hp/7.5kw motor is mounted directly to a two stage gearbox.

- An AC inverter drive provides a large range of blade speeds, ensuring efficient cutting of all profiles and materials.

- The direct down-feed system allows easy adjustment of the feed rate and cutting system.

Digital Feedback

- The standard digital display provides easy-to-read feedback on the angular position of the blade as well as blade cutting speed.

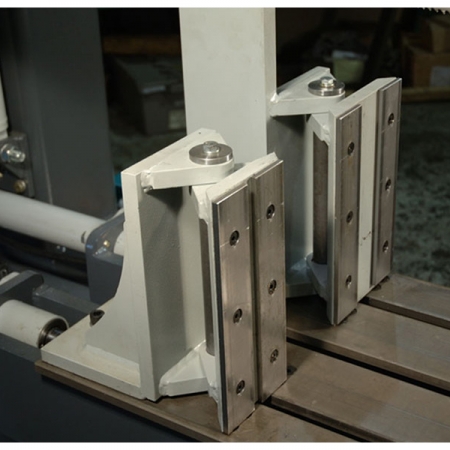

Positive Clamping

- The dual vises provide material clamping on both sides of the blade, and positively grip the material at any miter angle.

- As standard equipment, the Terminator Band Saw series are equipped with a plunger-style overhead clamp, reducing cutting vibration on large structural shapes, increasing cutting accuracy.

Reduced Setup Time

- The idler-side guide arm moves in tandem with the front moveable vise, ensuring proper positioning of the guide arm relative to the material width at all times.

- Replaceable carbide insert guides housed in the guide arms provide exceptional accuracy and vibration dampening.

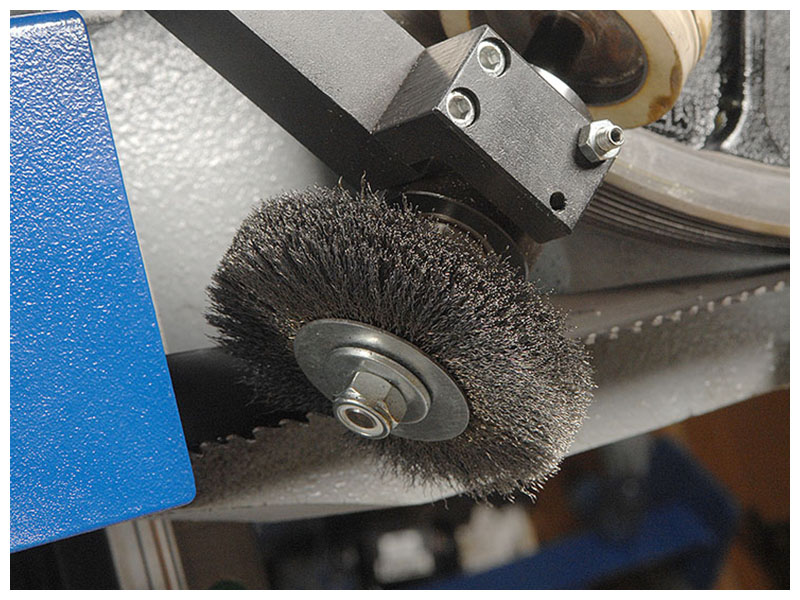

Long Blade Life

- A hydraulically driven blade brush keeps the blade gullets clean, maximizing blade performance and life. The large 30-gallon coolant reservoir and pump delivers ample coolant flow through the nozzles to the carbide faced guides.

- A wash down hose and spray gun comes standard with this machine.

Simple to Operate

- The Terminator’s pedestal mounted console can be positioned for best operator viewing and safety. The selector switches and push-buttons allow the operator to control all machine functions.

SPECIFICATIONS

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.