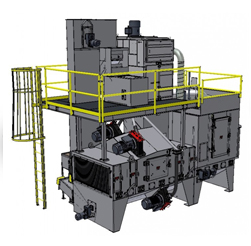

Ultra Compact Self-Contained Shot Blast Plant.

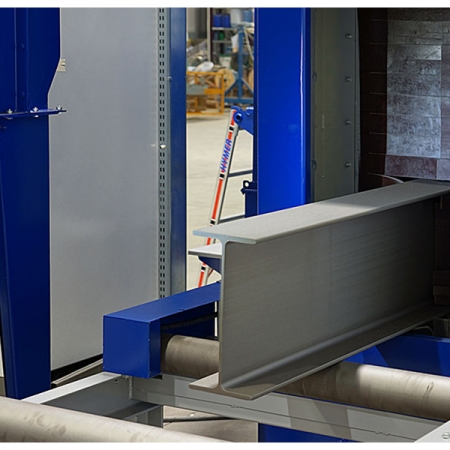

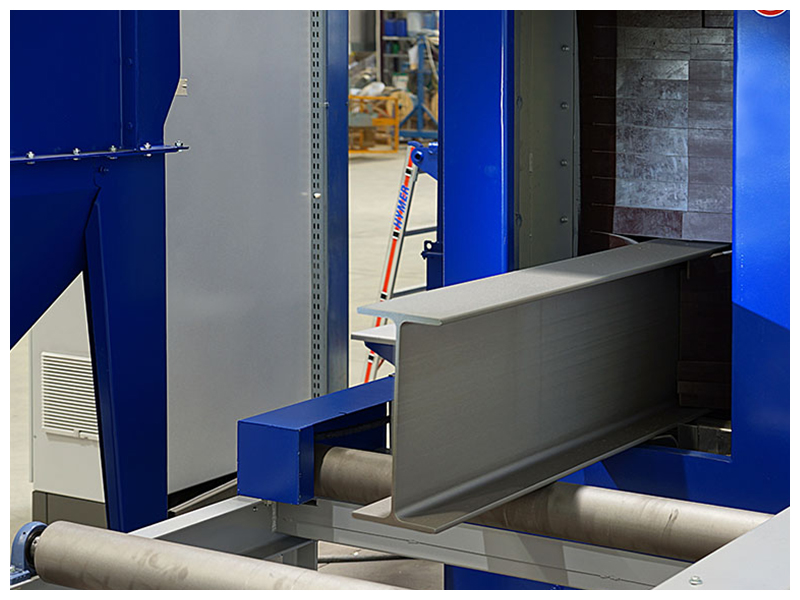

The Ocean Machinery Blaster Shot Blasting System is a completely unique shot blasting machine for cleaning structural steel sections.

For most fabricators, the traditional shot blaster has been way too large and too expensive to even consider, but this ultra-compact, fully integrated, exceptionally efficient shot blast machine will fit any steel fabricators space and budget requirements. The entire Ocean Blaster Shot Blasting System, including dust extraction unit, requires only 12ft x 25ft of floor space and only 13ft of headroom, making it ideal for even the smallest fabricating shops. Despite its compact size the Blaster will handle all profiles up to 40” tall and 20” wide.

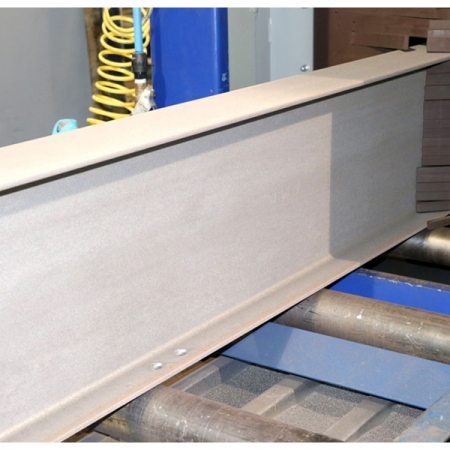

The exceptionally efficient turbine design allows fabricators to clean steel with the lowest power consumption, reducing costs even further. And pre-blasting of steel reduces grinding and cleaning, reduces rework, and creates a clean work environment improving morale and safety.

Why Ocean Machinery Blaster Shot Blasting System?

- The Blaster has been designed for ease of use. From its simple operating procedures to the simplicity of changing filters and components, working and maintaining the Ocean Blaster could not be easier.

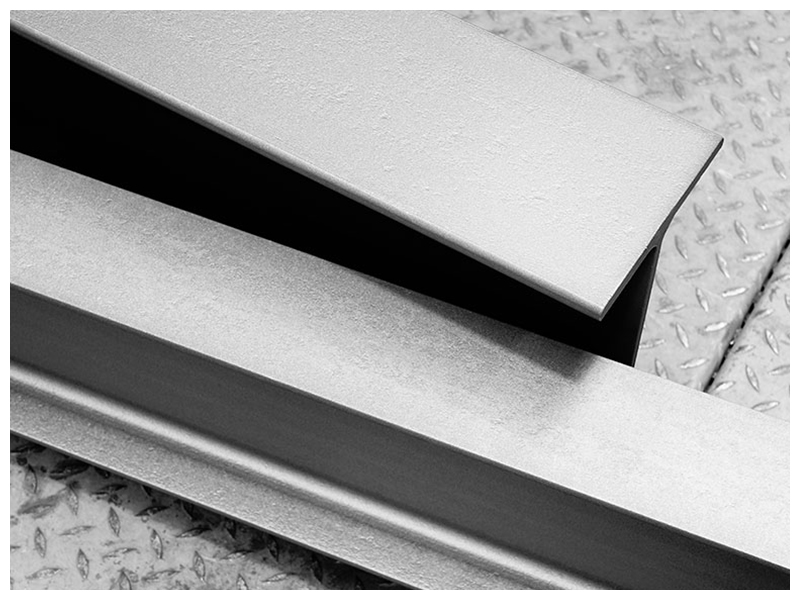

- The Blaster shot blasting system will handle a wide variety of shapes and sizes up to 40 inches (1m), and can produce surface conditions up to White Metal Blasting SSPC SP5 (NACE 1) specification.

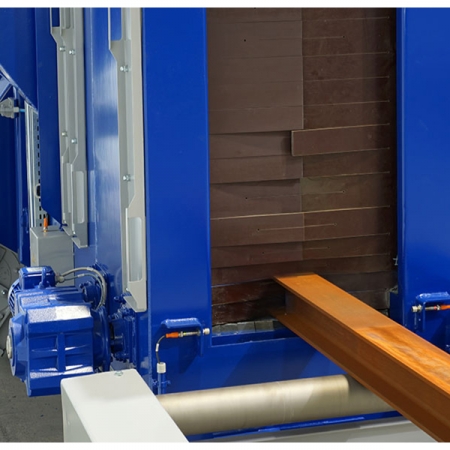

- The blast cabinet is made of manganese steel for long life and is further reinforced with replaceable manganese liner plates. This well sealed chamber stops rust and dust particles from entering the shop.

- The heavy duty, variable speed chain driven internal roller conveyor is easily connected to extension input and output conveyors. Transfer speed is easily adjusted to achieve the desired surface finish.

- The conveyor speed monitor automatically controls the starting and stopping of the shot blast action.

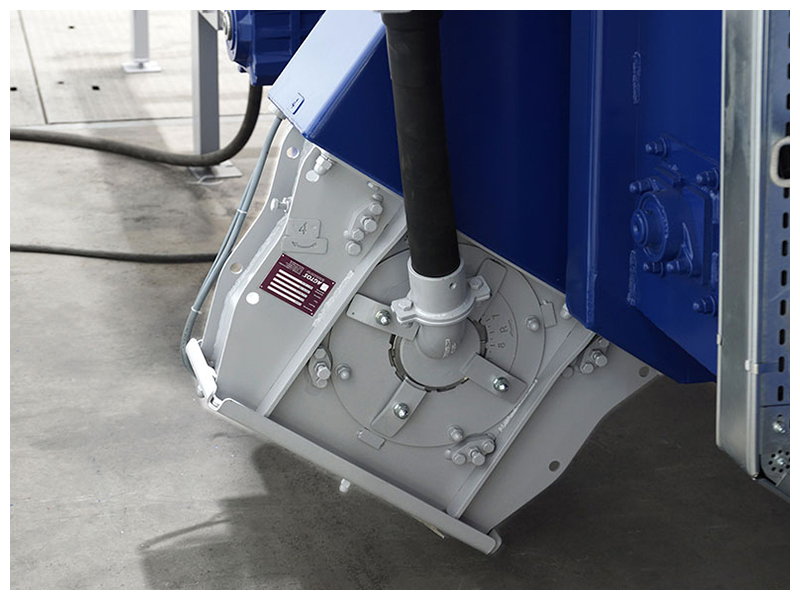

- Four highly efficient direct drive Agtos High Performance Turbine blast wheels achieve the highest surface finish quality while requiring less power, further reducing cleaning costs.

- The machine is completely integrated and only requires infeed and outfeed conveyors.

- The complete abrasive recycling system comprises collection hopper, screw conveyors, two bucket elevators, air separator, drop-out box, maintenance platform and four high-performance turbines with abrasive flow-control units.

- The high velocity abrasive blow-off unit at the cabinet exit keeps the shot in the system and out of your shop.

- Within the abrasive recycling system, a large highly efficient air wash separator prolongs shot life and a drop-out box removes coarse particles to avoid destruction of filter elements.

- All inspection ports are easy to access and a maintenance platform is standard.

- The simple maintenance requirements, the reduced abrasive consumption and reduced energy consumption all add up to a significant reduction in operating costs.

- An integrated air filter unit with long-life conical elements effectively removes dust from the system, and returns clean air to the shop. This filter system is self-cleaning and the filter elements are easily replaced after many hours of use.

- A central electrical cabinet provides complete control of the unit with ammeter display for control of turbines, working and blasting hour counters, lighted control switches, fault indicator lamps, speed controller, master switch and emergency stop switch.

One Anderson.

Corporate, Machinery SolutionsAkhurst has made the move to distribute all of Anderson’s machines under one brand, Anderson. Anderson is the world leading CNC router manufacturer, with over 20 thousand machines sold worldwide and 5 thousand only in the US market.

Visit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Corporate, Machinery Solutions, Trade ShowsThe WTD is back with extended dates, now giving visitors five days to visit our members’ extensive showrooms and see the latest new technology, including some North American premieres. No other show or single event offers you such a wide display of woodworking equipment, combined with impressive live demonstrations at each location.

High-end cabinetry, movie stars, Marvel has it all.

Case Study, Corporate, Machinery Solutions, Service and SupportMarvel Cabinetry, from De Winton, AB, is the exclusive cabinetry supplier for the first and second seasons of Property Brothers’ Celebrity IOU on HGTV, and has designed and built made-in-Canada cabinetry for stars across North America. Among them were Michael Bublé, Brad Pitt, Snoop Dogg, Gwyneth Paltrow, Melissa McCarthy, Viola Davis, Jeremy Renner, Kevin Hart, Howie Mandel, and LeAnn Rimes, and Marvel invites you to be next.