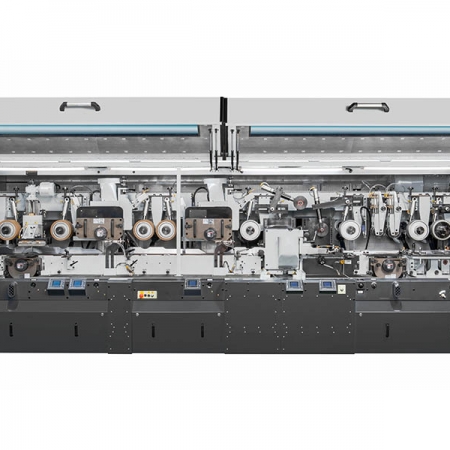

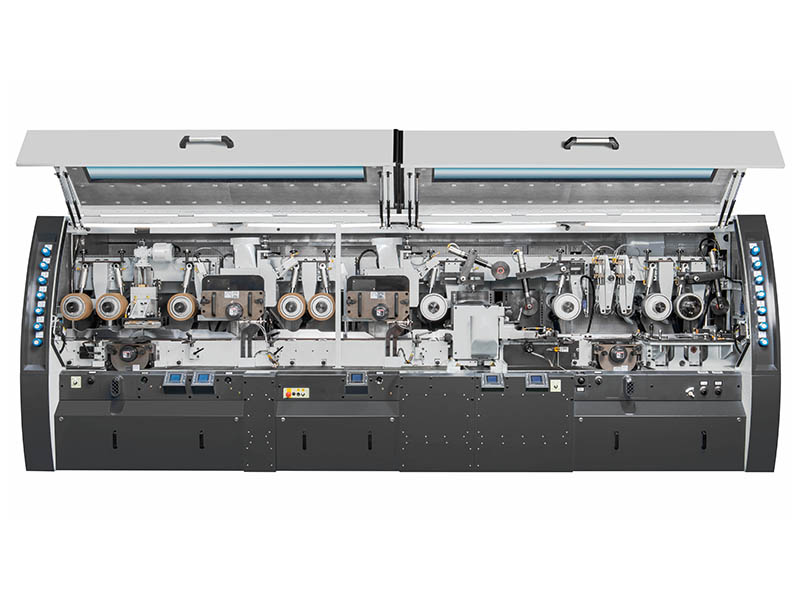

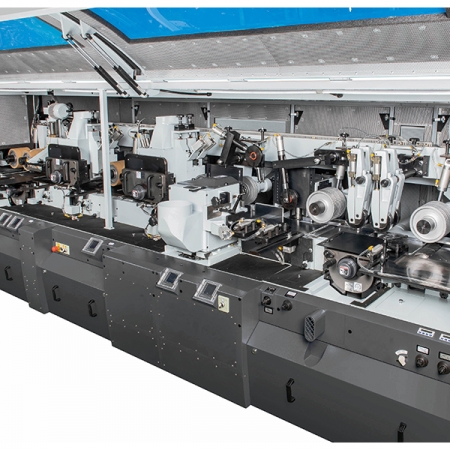

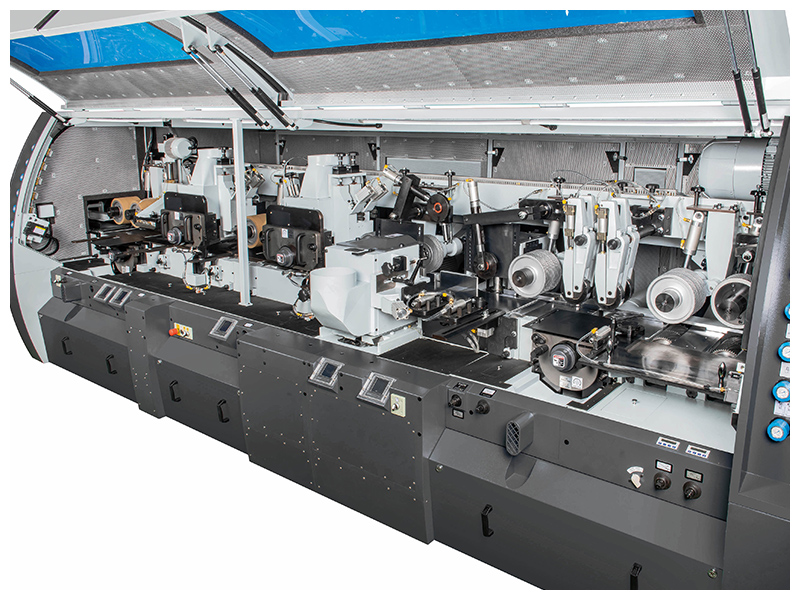

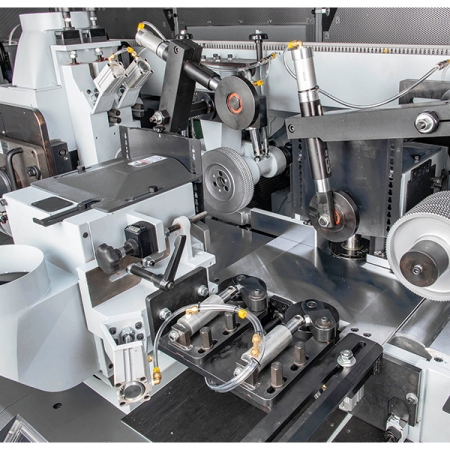

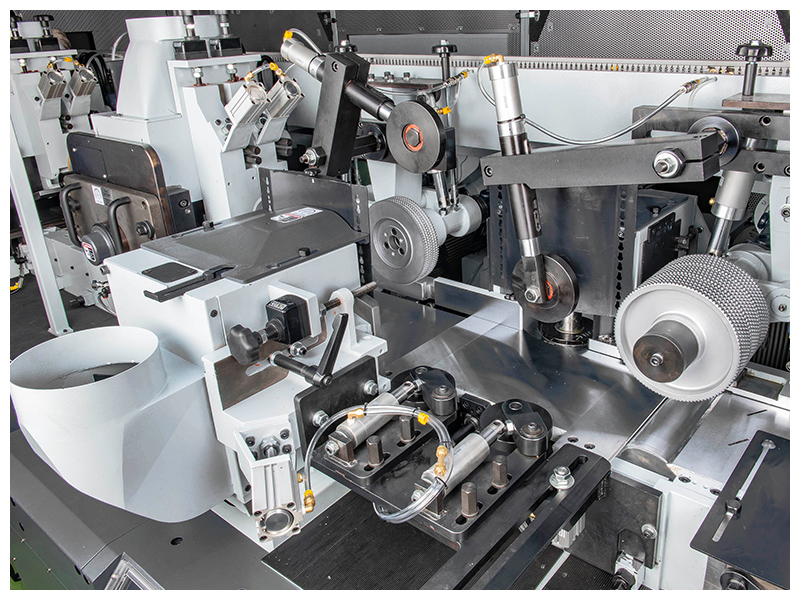

A heavy duty, jointed, high speed moulder designed for the production of flooring, finished mouldings, and basic four-sided planing of lumber.

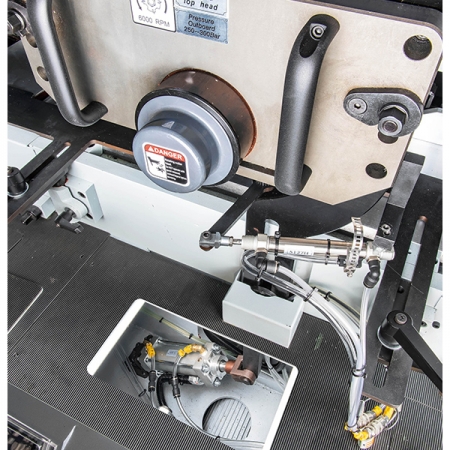

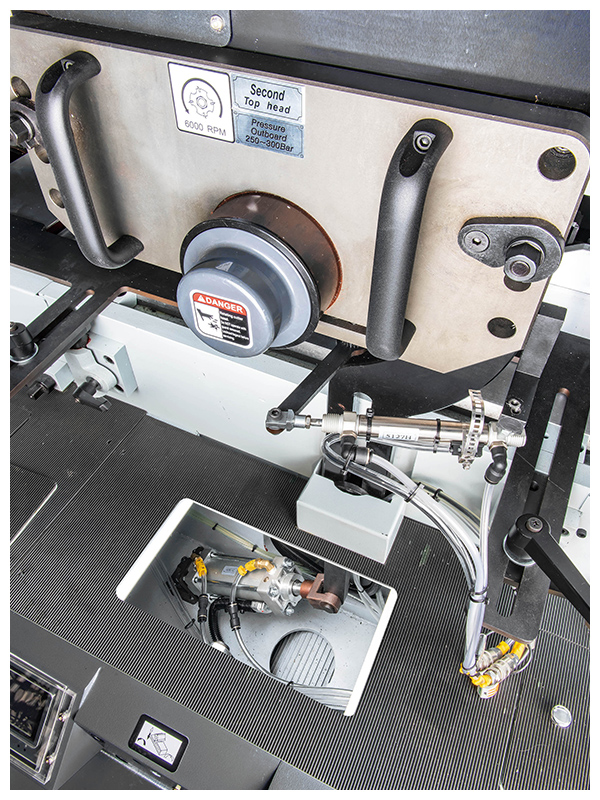

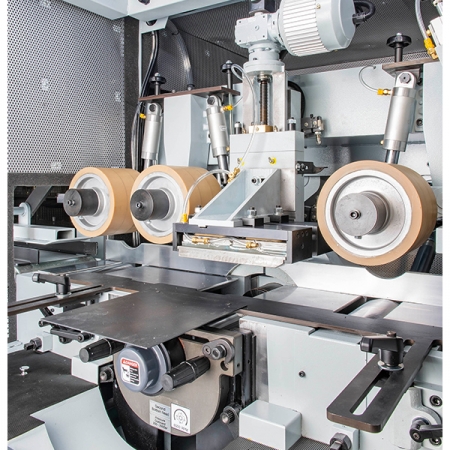

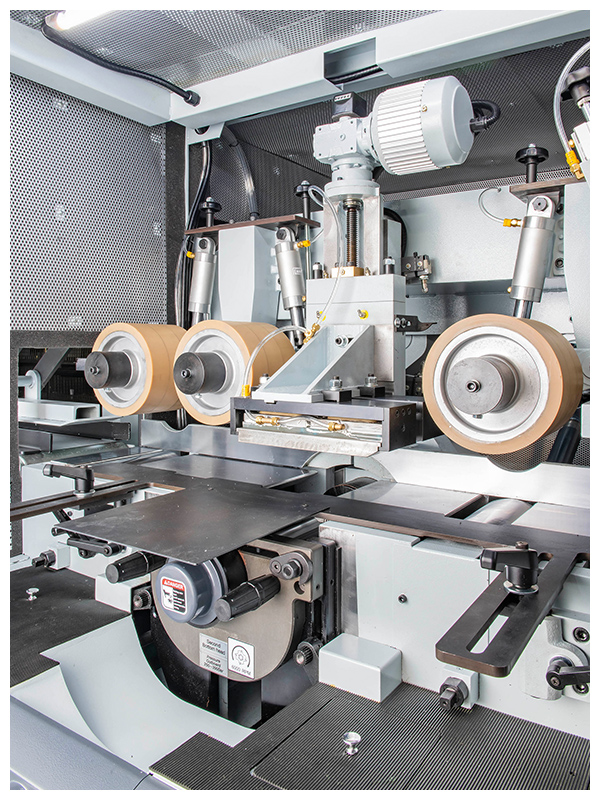

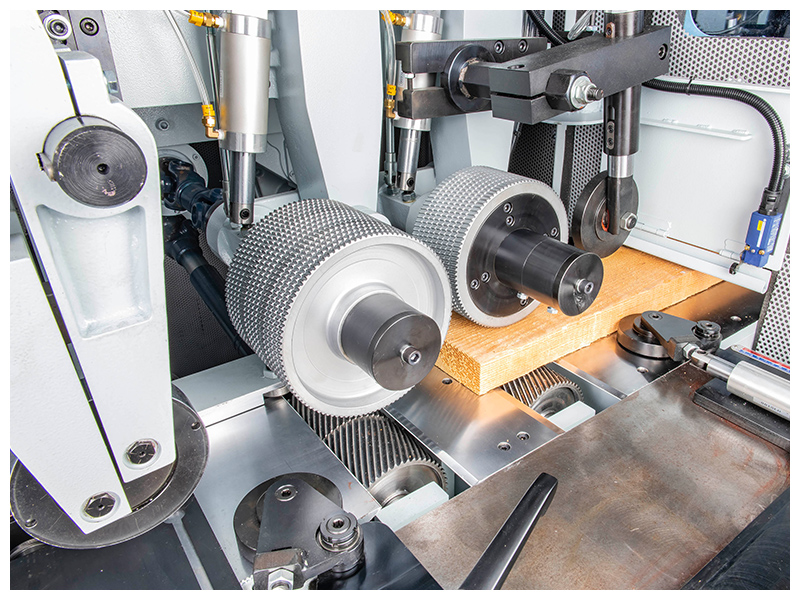

The Leadermac Thundermac Moulder Series is a heavy duty moulder designed to run at high speeds and with the ability to handle a wide range of applications to meet your requirements. The Thundermac moulder is available with profile and straight jointers and has feed speeds from 200 to 650 fpm, producing an excellent quality finish. The feed system is designed to handle rough or pre-sized material and is built to run in demanding multiple shift operations, ensuring maximum uptime.

Why Leadermac Thundermac Moulder Series?

- Heavily built cast iron or fabricated steel frame ensures the production of quality finished products at high speed rates.

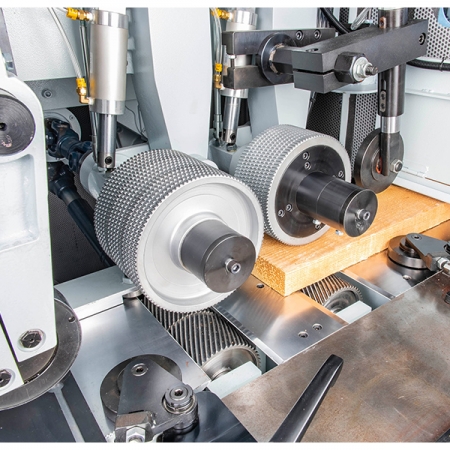

- Precision spindle assemblies including four high-precision bearings, each for the highest tolerances and superior finish results.

- A wide range of automation options available on the standard Setworks control to provide the operator with fast and repeatable set ups with reduced changeover time

KEY ADVANTAGES

- Industrial moulder design with a solid cast iron or fabricated steel frame produces unparalleled finished part quality in its class.

- The Thundermac moulder comes with high-quality components, ensuring the best finish possible.

- 4 pieces of Abec 7 Precision Bearings per spindle – ensuring an excellent finish on your products.

- The Thundermac moulders design ensures easy and consistent set up by your operator, ensuring quick changeovers.

- Turnkey solutions include on-site operator and maintenance training.

KEY FEATURES

SPECIFICATIONS

OPTIONS

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.