Powerful, precise, and efficient roll feed ripsaws.

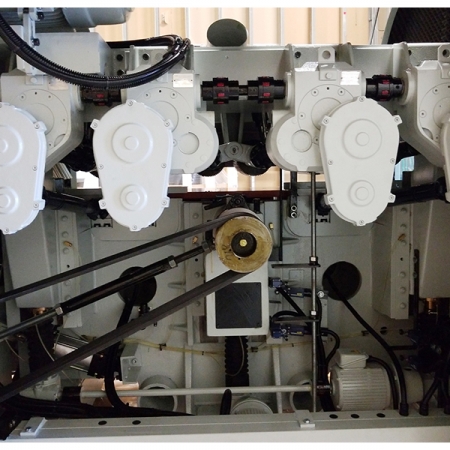

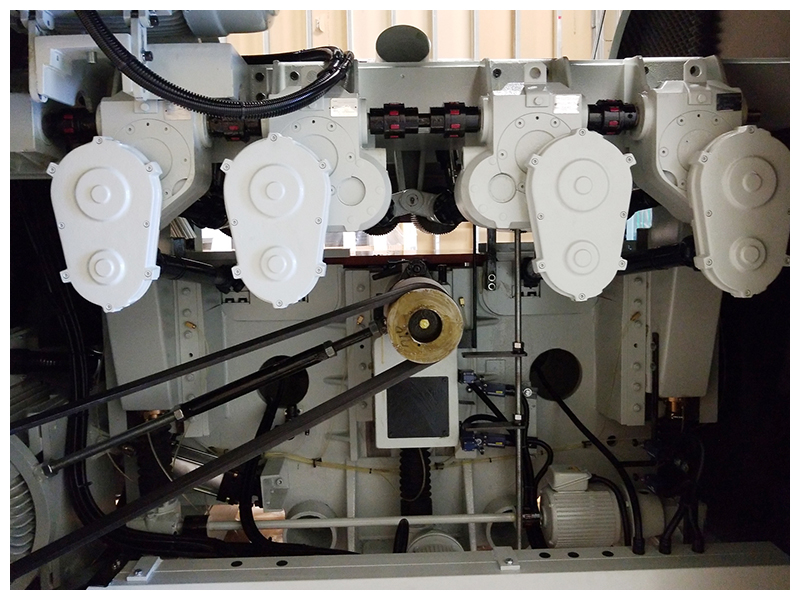

The Leadermac SYC Series Roll Feed Ripsaws has been designed to ensure uncompromised results specifically aimed to the company looking to run strip materials like lath, dunnage, stakes, and more. The roll feed design will rip for maximum material yield which helps increase output and margins.

Why Leadermac SYC Series Roll Feed Ripsaws?

- Roll feed design achieves maximum yield from the material

- Heavy frame ensures smooth running to allow thin cutting of materials like lath

- Full width top and bottom driven feed rolls assist in smooth feeding of a range of materials thru the ripsaw

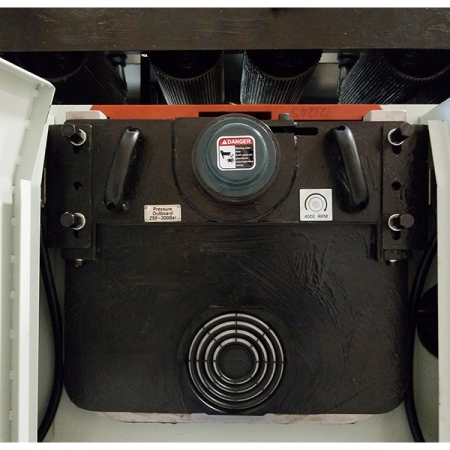

- Fully enclosed design, along with multiple anti kickbacks ensure a safe operating machine

- Bottom cutting with known safety advantages

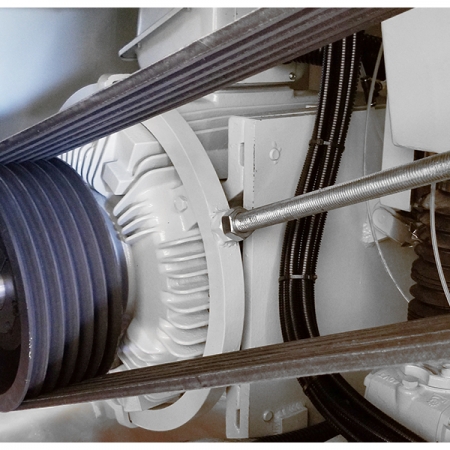

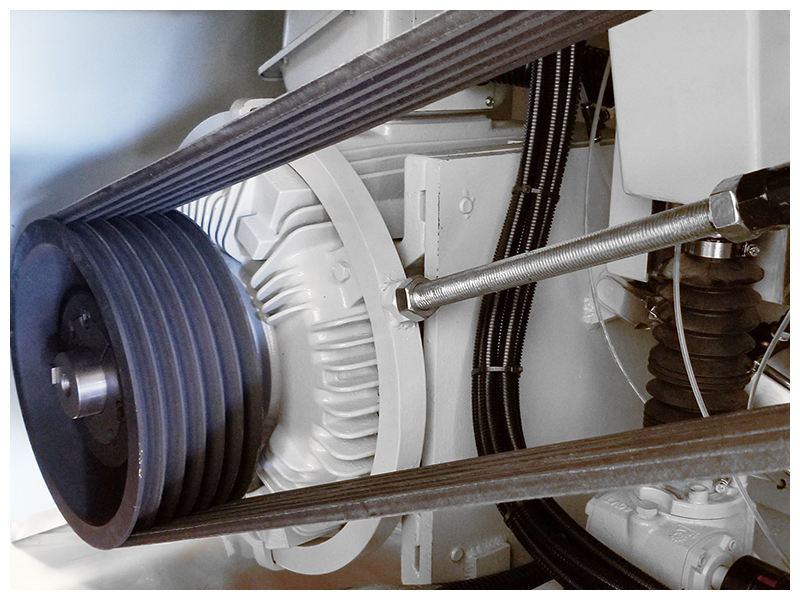

- Outboard spindle bearing support for precision cutting results

- Available in a wide range of widths and configurations to suit any applications and budget

KEY ADVANTAGES

- Heavy cast iron base provides best rigidity and reduces vibration for rip cutting results

- (6) top driven feed roll assemblies for optimum material control

- (4) bottom driven feed roll assemblies facilitate in feeding difficult to feed material

- Blades are mounted to a removable saw sleeve which allows the operator to pre-build different ripping setups and facilitates in fast changeovers

- A number of features are integrated in to the machine to ensure safe operation

SPECIFICATIONS

OPTIONS

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.