Powerful, precise, efficient moulder, available in a configuration to meet your requirements.

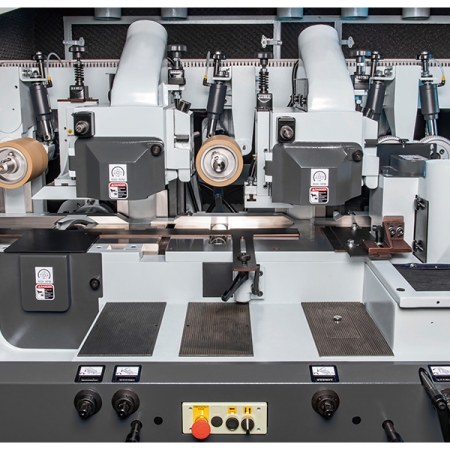

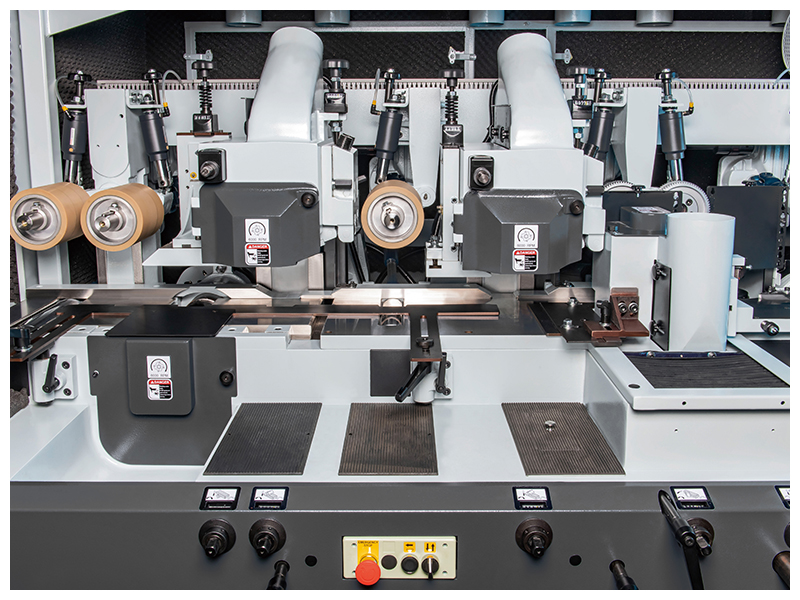

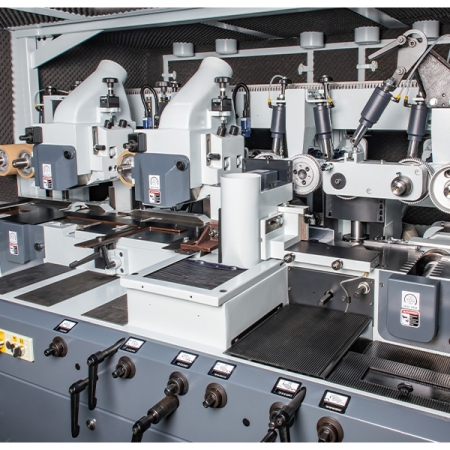

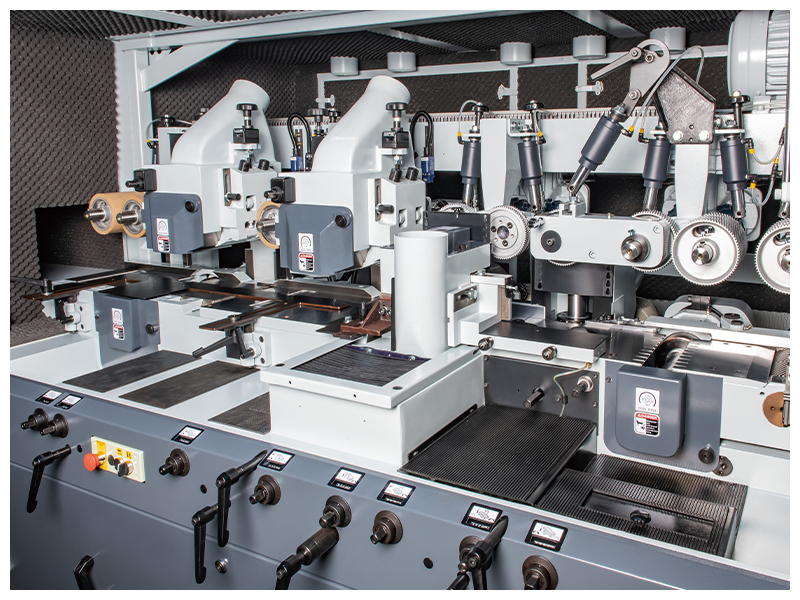

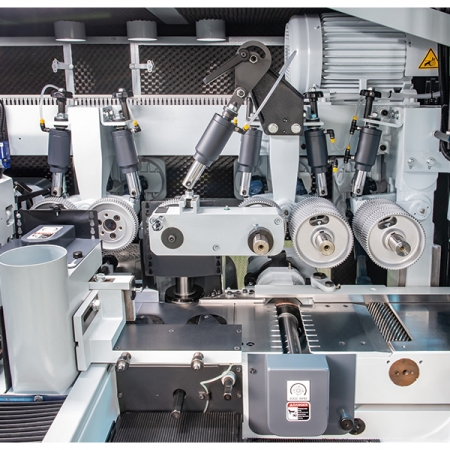

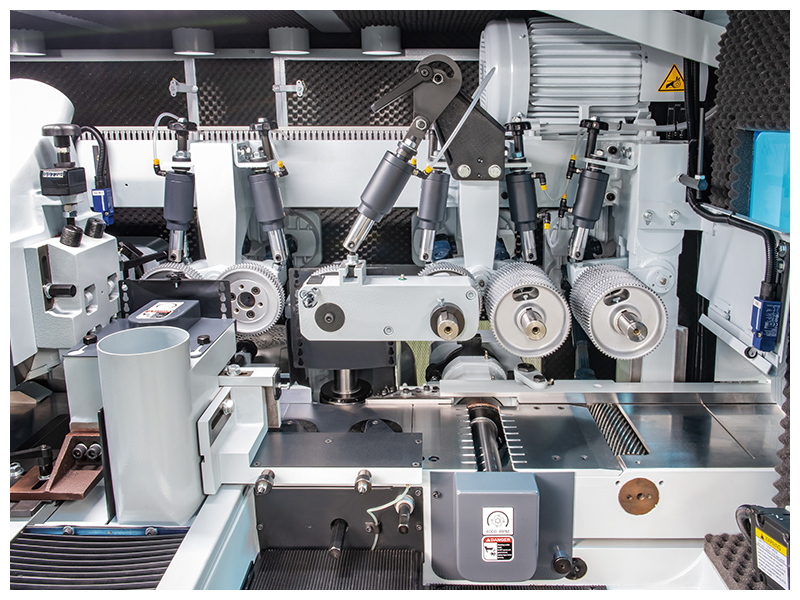

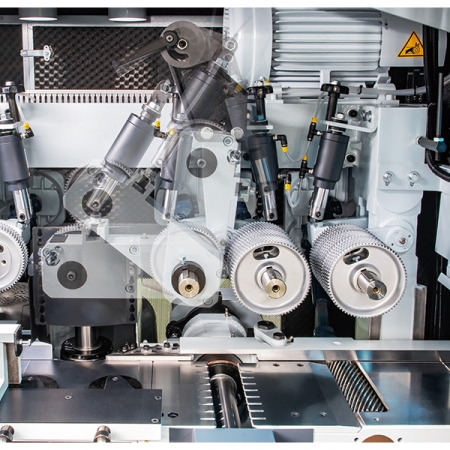

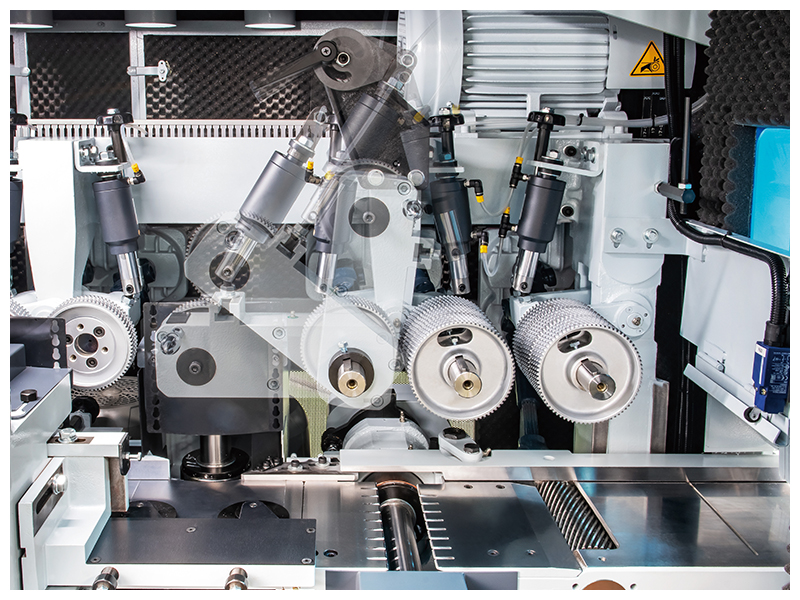

The Leadermac Compact Moulder Series has been designed to ensure a high-quality finish, with a range of options to meet your particular needs. The Compact is a tight coupled machine to ensure total control and smooth feeding of the workpiece as it passes thru. Many powerful features come standard with the Compact, ensuring fast and repeatable setups with reduced changeover time, allowing you to meet your production requirements day in and day out.

Why Leadermac Compact Moulder Series?

- Industrial moulder design with a solid cast iron frame produces unparalleled finished part quality in its class.

- Despite its competitive price point, the Compact moulder comes with high-quality components, ensuring the best finish possible.

- The Compact moulders design ensures easy and consistent set up by your operator, ensuring quick changeovers and high-quality finished product results.

- Turnkey solutions include on-site operator and maintenance training.

KEY ADVANTAGES

- Heavy-duty cast iron frame provides superior vibration damping, which produces superiorly finished parts and promotes long bearing & machine life.

- Tightly coupled machine ensures smooth and consistent feeding to assist in producing high-quality finish.

- All tables and fences hard chromed with approximately 0.012”-0014” thick hard chrome, which ensures maximum longevity.

- Comes with more top-driven and bottom full-width driven feed rolls than other moulders of its size.

- 6000 RPM spindles each with (4) ABEC 6 precision bearings per spindle which provides smooth surface finish results.

- All spindles driven by individual motors.

- Pneumatic side holdover provides consistent side pressure to the fence.

- Pneumatic hold down pressure to all top feed rolls provides consistent and repeatable pressure.

- Pneumatic chip breakers ensuring consistent pressure.

- Full width driven infeed & outfeed bed rolls.

- Short stock feed roll station.

- Dual SIKO quick set counters to assist in quick and accurate changeovers (other setworks systems available to increase automation).

- Axial adjustment of last bottom head from front of machine.

- Automatic and programmable table lubrication system.

- Centralized grease lubrication system.

- Safety sound enclosure is standard.

- Pneumatic pressure to chip breakers, holdovers, and top feed rolls.

SPECIFICATIONS

OPTIONS

One Anderson.

Corporate, Machinery SolutionsAkhurst has made the move to distribute all of Anderson’s machines under one brand, Anderson. Anderson is the world leading CNC router manufacturer, with over 20 thousand machines sold worldwide and 5 thousand only in the US market.

Visit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Corporate, Machinery Solutions, Trade ShowsThe WTD is back with extended dates, now giving visitors five days to visit our members’ extensive showrooms and see the latest new technology, including some North American premieres. No other show or single event offers you such a wide display of woodworking equipment, combined with impressive live demonstrations at each location.

High-end cabinetry, movie stars, Marvel has it all.

Case Study, Corporate, Machinery Solutions, Service and SupportMarvel Cabinetry, from De Winton, AB, is the exclusive cabinetry supplier for the first and second seasons of Property Brothers’ Celebrity IOU on HGTV, and has designed and built made-in-Canada cabinetry for stars across North America. Among them were Michael Bublé, Brad Pitt, Snoop Dogg, Gwyneth Paltrow, Melissa McCarthy, Viola Davis, Jeremy Renner, Kevin Hart, Howie Mandel, and LeAnn Rimes, and Marvel invites you to be next.