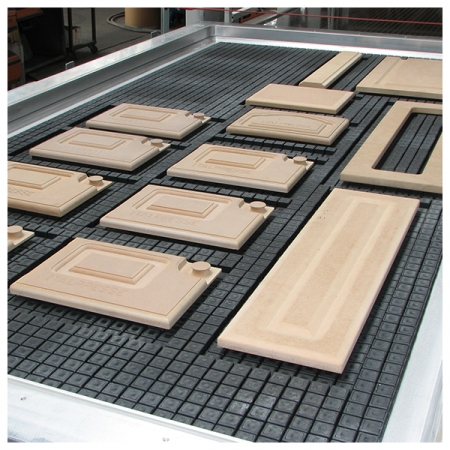

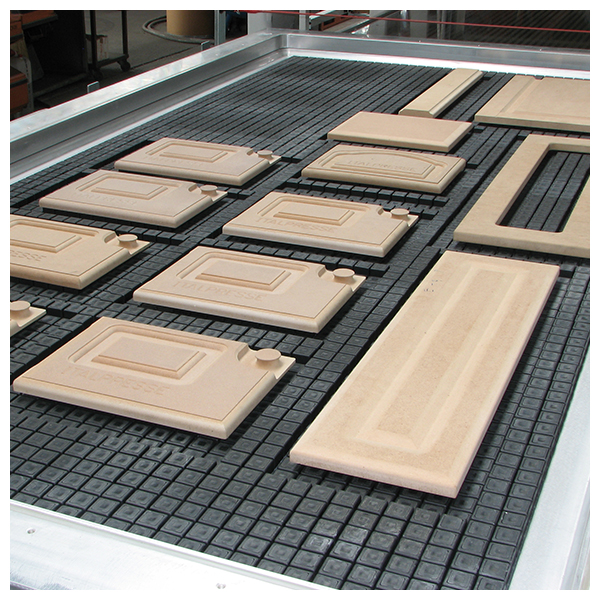

Producing high quality 3D cabinet doors with decorative finishing surface.

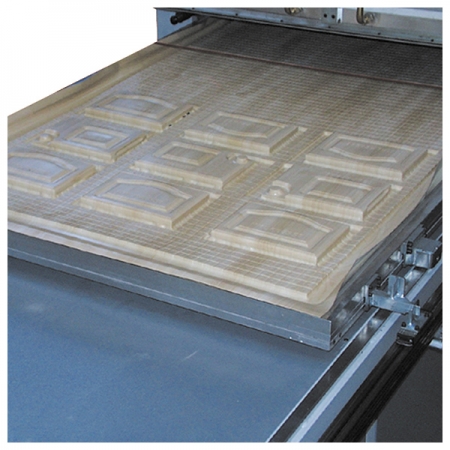

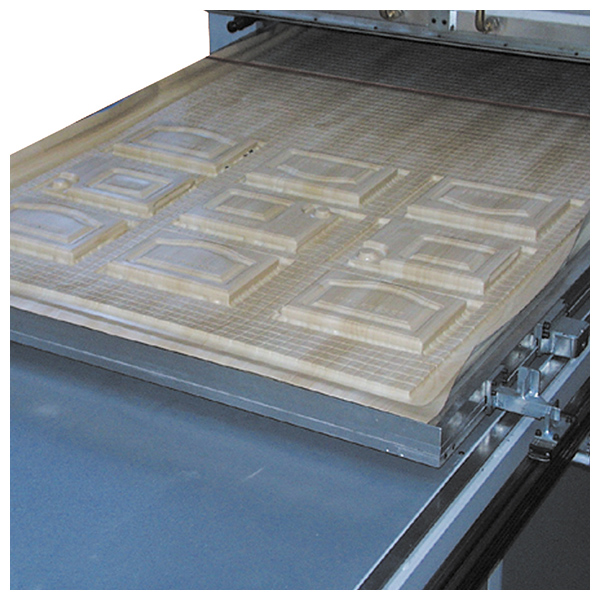

The Italpresse Estrema Air Membrane Press was designed to produce the highest quality of the end product, with extremely fast pressing cycles, quick production changes, and unparalleled user integration for thermoforming materials (PVC, PPE, ABS, TRANSFER FOILS; etc ) or natural veneers. The primary output of this machine is beautifully aesthetic and durable cabinet doors which are created efficiently and economically.

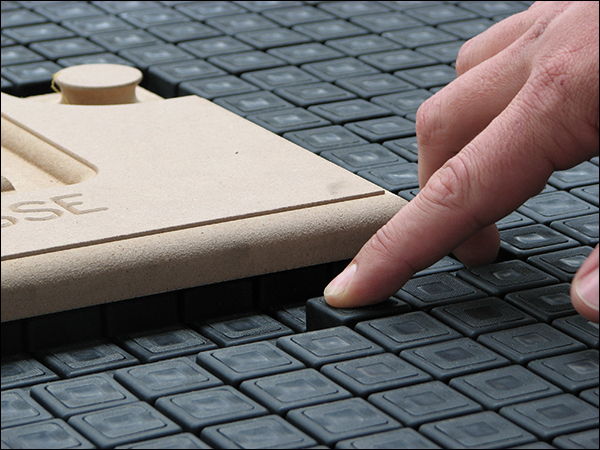

The Italpresse Estrema can be run with a membrane or membrane-less and can be supplied with one to three trays with manual or automatic movement. The trays can be equipped with the exclusive Italpresse PSS (PIN SUPPORT SYSTEM) that completely eliminates the need for panel raisers and accelerates the production output.

Why Italpresse Estrema Air Membrane Press?

- High production output of thermoformed cabinet doors & panels

- Short cycle times & superior output quality with vacuum + positive pressure

- Suitable for PVC, PPE, ABS, transfer foils, or natural veneers

- Possibility to run with or without a membrane and programs suited to your material and needs

- User friendly touch screen interface allows full control of machine functions with capability to store working programs for instant recall

- Available with one or two loading trays according to output requirements

- Manual or automatic tray loading

- Models with 4’x9’ or 4’x10’ useable press size

- Solid steel frame which is precision machined by CNC

- Top heating platen with direct electric heating and oil circulation for a higher degree of temperature uniformity

- Maximum platen temperature up to 150o C

- High thickness monolithic steel bottom platen

- Touch-screen color operator interface with possibility to set and store working programs

- Large diameter hydraulic pressure cylinders

- Vacuum system complete with pump and control valve to ensure optimum transfer of the foil to the substrate

One Anderson.

Corporate, Machinery SolutionsAkhurst has made the move to distribute all of Anderson’s machines under one brand, Anderson. Anderson is the world leading CNC router manufacturer, with over 20 thousand machines sold worldwide and 5 thousand only in the US market.

When does pre-milling make sense?

Machinery Solutions, Service and SupportOver the past few years, pre-milling has grown in popularity. Pre-milling is the process of machining the edge of the panel prior to applying glue. It ensures optimal edge quality before the application of edge banding, resulting in reduced glue joints and a highly aesthetic edge.

Visit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Corporate, Machinery Solutions, Trade ShowsThe WTD is back with extended dates, now giving visitors five days to visit our members’ extensive showrooms and see the latest new technology, including some North American premieres. No other show or single event offers you such a wide display of woodworking equipment, combined with impressive live demonstrations at each location.