Proven sanding performance with the power of a BULDOG.

The Houfek BULDOG 7-3M-1100-RRC 43” Three Head Widebelt Sander was designed for those requiring simplicity, reliability, and quality in their sanding applications. It is equipped with two longitudinal calibrating sanding heads and 1 combination drum/platen finish sanding head. With this configuration you have a versatile sanding machine which can do it all.

Why Houfek BULDOG 7-3M-1100-RRC 43″ Three Head Widebelt Sander

- Robust welded steel frame

- 18 kW motor on first head, and individual 15 kW motors on second and third heads

- Adjustable sanding units (upper part of machine)

- Flanged drive motors for drive of working units are mounted on the bottom of machine frame to minimize floor space requirements

- Variable feed speed

CONFIGURATION

- 3 sanding units – Roller / Roller / Combination-head.

- 1st Roller – Rubber – 90 shore @ 200mm dia.

- 2nd Roller – Rubber – 90° shore @ 2000mm dia.

- 3rd Roller – Rubber – 45° shore @ 200mm dia. with adjustable platen.

- Electropneumatic lifting of all rollers & platen from the control panel.

- Oscillating abrasive belt cleaning device, timed, (all heads).

- Automatic Star Delta switch.

- Amp meters for each sanding unit.

- Optoelectronic sensors for sanding belt oscillation.

- Automatic feed belt tracking.

- Mechanical limitation of maximum stock removal.

- Panel cleaning device, motorized with 100mm diameter dust port connection.

- Motorized height adjustment of the sanding units (machine opening)

- ELGO P40 Machine control:

- Automatic adjustment of machine opening to set position.

- Electronic measuring of table position with digital display.

- Digital display of feed belt speed.

- Automatic adjustment of sanding unit to set position.

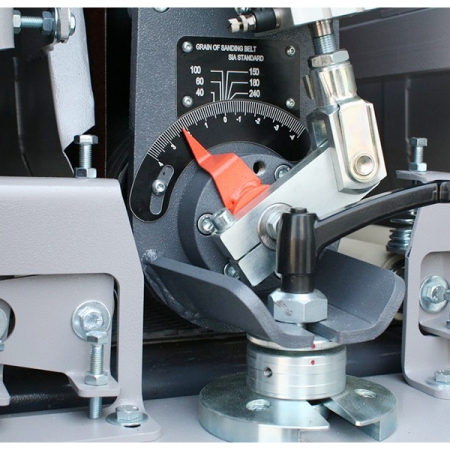

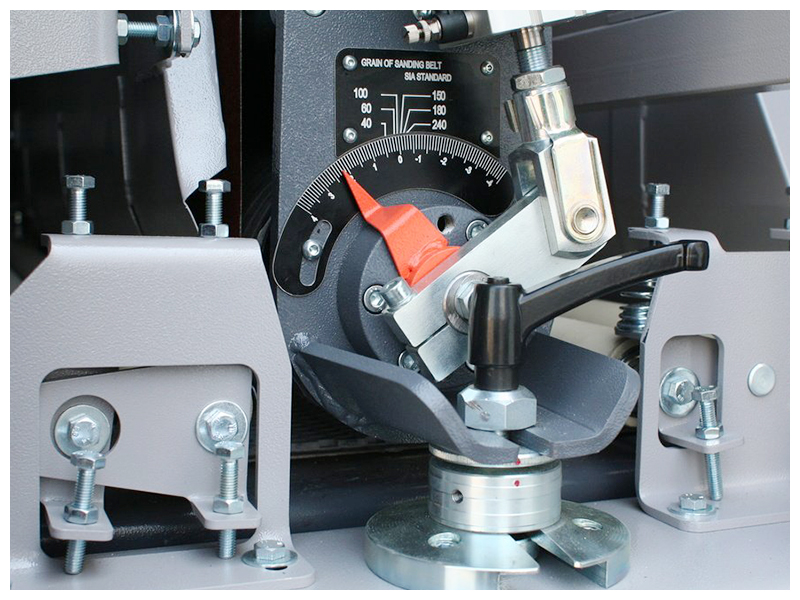

- Electronic height correction by abrasive belt grit rating.

- Work piece thickness measuring

- All sanding heads are equipped with emergency braking system. The system uses compressed air to release the brakes. In the event of loss of compressed air to the machine the power to the motors is stopped and the braking system is activated by a spring system. This system is very simple and reliable.

- Vacuum table with blower and silencer to hold small parts onto the feed belt.

- 3 infeed and 2 out feed rubber pressure rolls.

- Canadian electrical package including CSA components.

- Electrical inspection for operation in Canada/USA.

SPECIFICATIONS

Sanding to Perfection: Achieving a Fine Finish.

Machinery Solutions, Service and SupportThe journey to a fine finish in sanding is the culmination of transforming raw wood into a refined and desirable surface, ready for the application of the final finishing products.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Why Consider a Planer Sander?

Machinery Solutions, Service and SupportTraditionally shops have a surface planer and/or wide belt sander to calibrate and prepare their products for finishing. Understanding the differences between a planer and a sander and how efficiently using a planer sander can benefit your production can be vitally important to your business saving time and money.