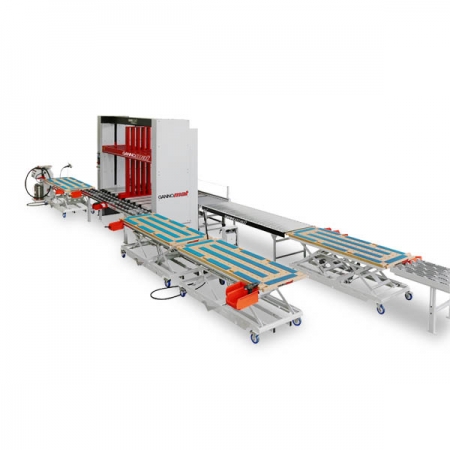

GANNOMAT

Concept Primus Case Clamp

Machine Information

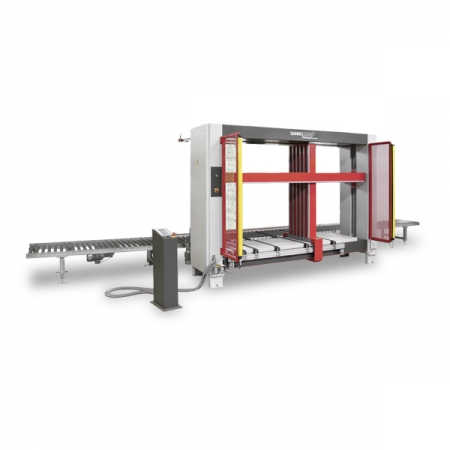

FEATURES

- Sturdy durable steel frame construction in welding and screw design

- TOP lamellar pressure beam with 7 machined steel bars (laminae), SIDE lamellar pressure beam with 6 machined steel bars (laminae)

- Lamellar clamping beam with workpiece tolerance compensation (System Ganner), proved in practice, for tight cabinet joints

- Counter-pressure (fixed sidewall, bottom) surfaces, 38 mm thick solid laminated continuous working platforms

- Electronic motorized adjustment of both pressure beams by precision trapezoidal-threaded spindles (with high thread lead and concentrated accuracy) and heavy-duty machine running nut with integral grease reservoir

- The pressing force of each pressure beam is stepless electronically controlled through the control and regulated by frequency changers, therefore the pressing force control is absolutely wear-free

- Pressing force of the top pressure beam (horizontal) min. 800 daN (kg) stepless till max. 3500 daN (kg)

- Pressing of the side pressure beam (vertical) min. 600 daN (kg) steplesx till max. 3500 daN (kg)

- Pressing velocity of the pressing beams with fine positioning, automatic controlled according chosen pressing force:

- 600 daN (kg) or 800 daN (kg) till 1100 daN (kg) Pressing velocity 5 mm/second

- 1200 daN kg) till 3500 daN (kg) Pressing velocity 10 mm/second

- Adjustment rate with rapid positioning 50 mm/second, controlled by automatic workpiece recognition with sensors in the laminae pressure beams

- Simple operation by electronic controller with LCD display and transparency-protected keyboard for: Main and PRE-PRESSURE INPUT (TOP and SIDE pressure separately) with electronic pressure monitoring. Pressure time pre-selection with automatic opening/item counter/self-diagnostics

Specifications