Improve your cabinet assembly times and optimize your product flow.

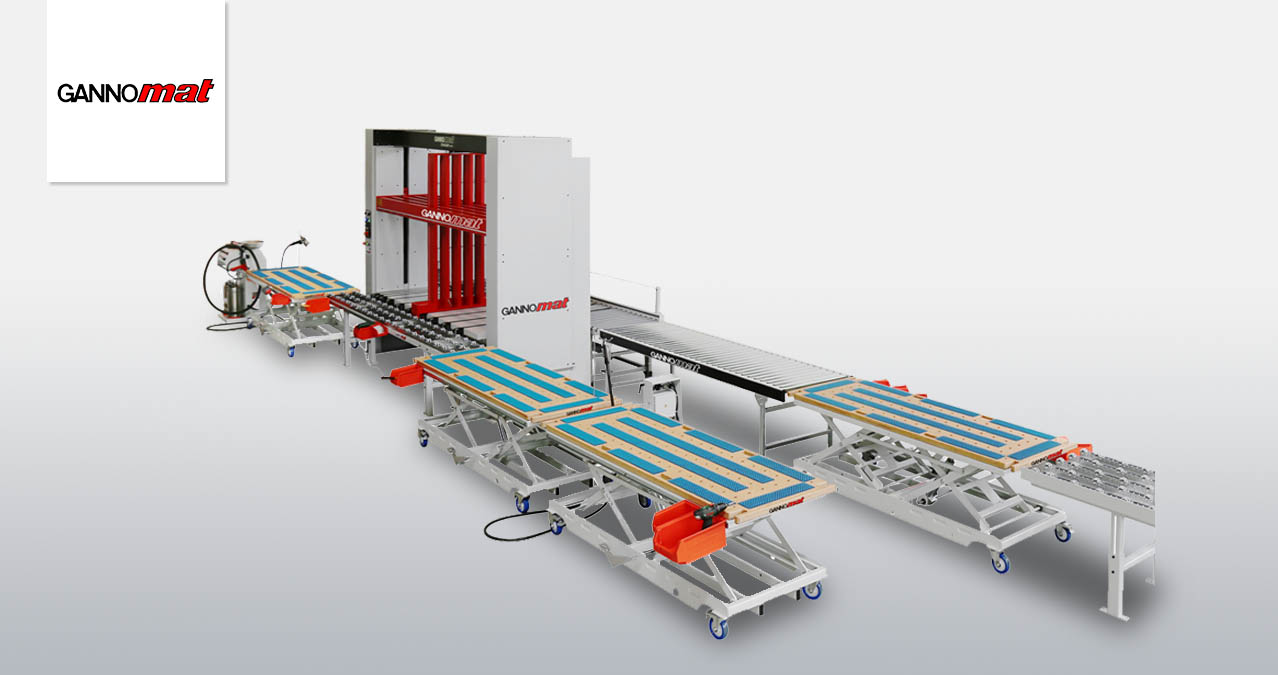

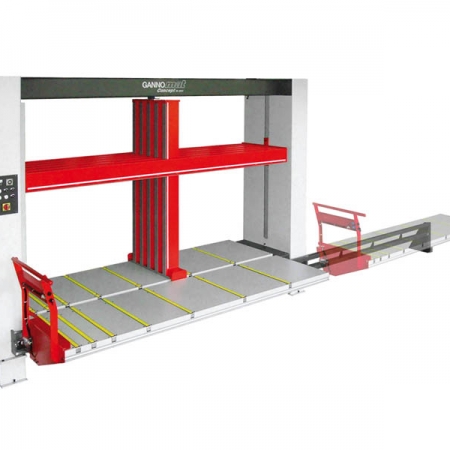

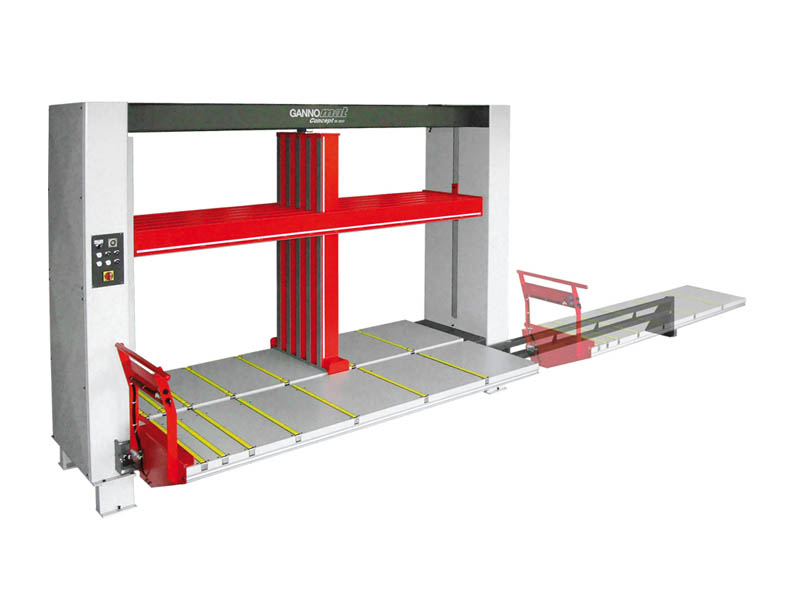

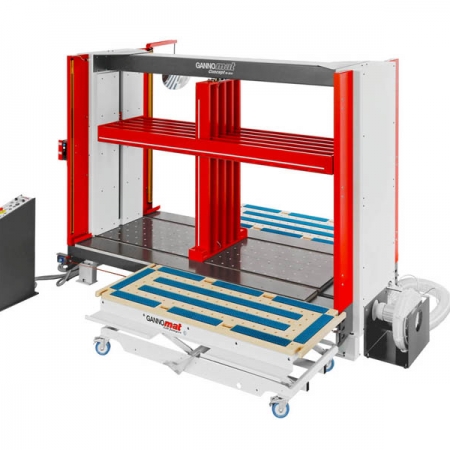

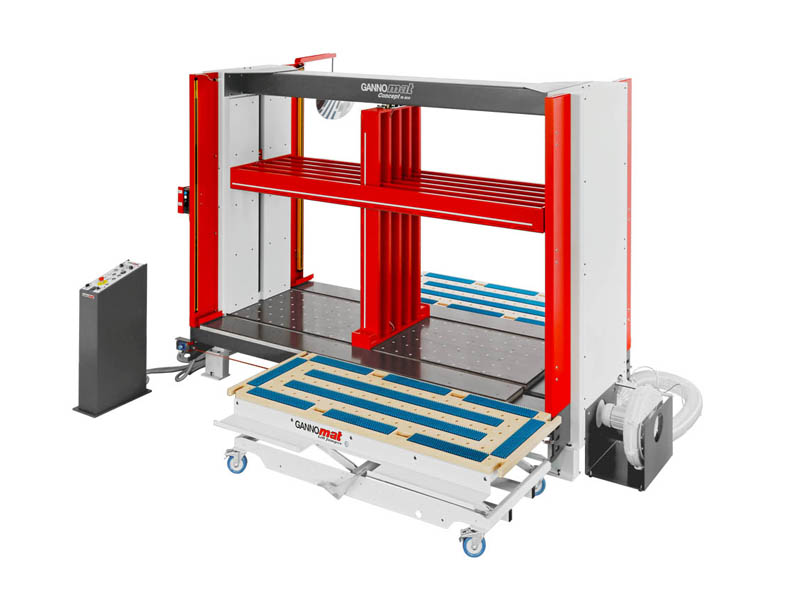

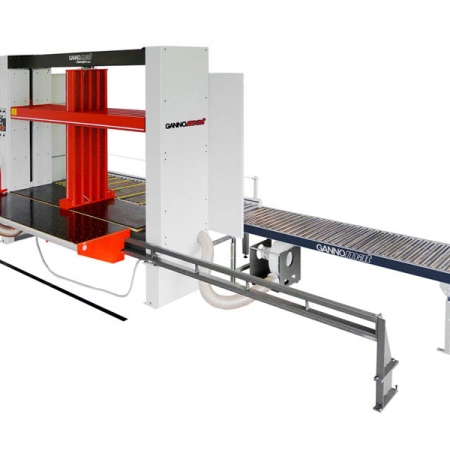

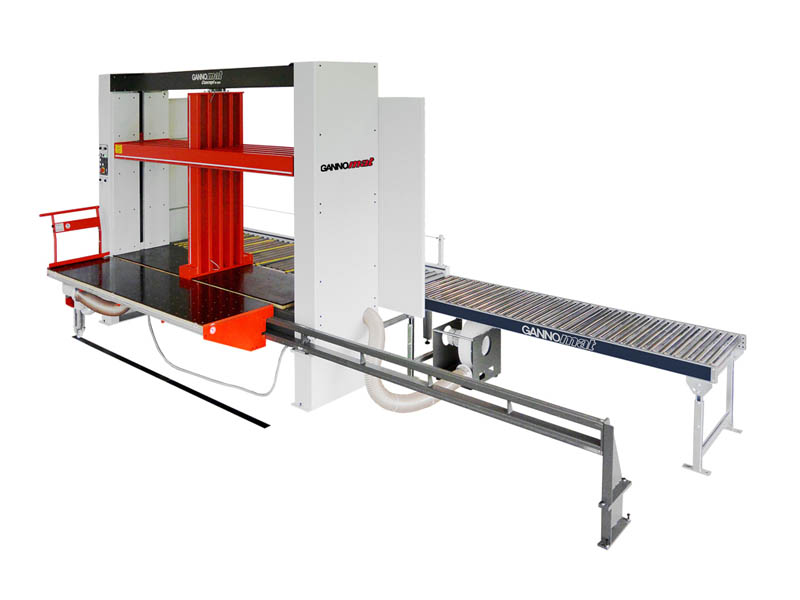

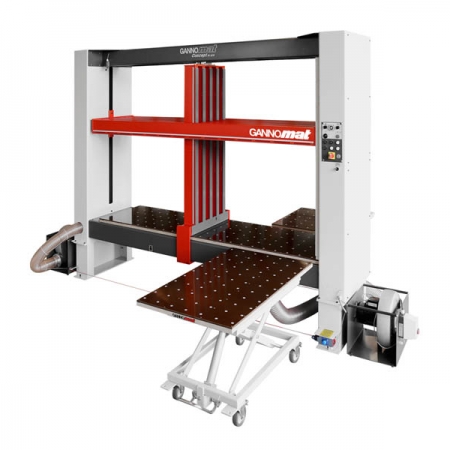

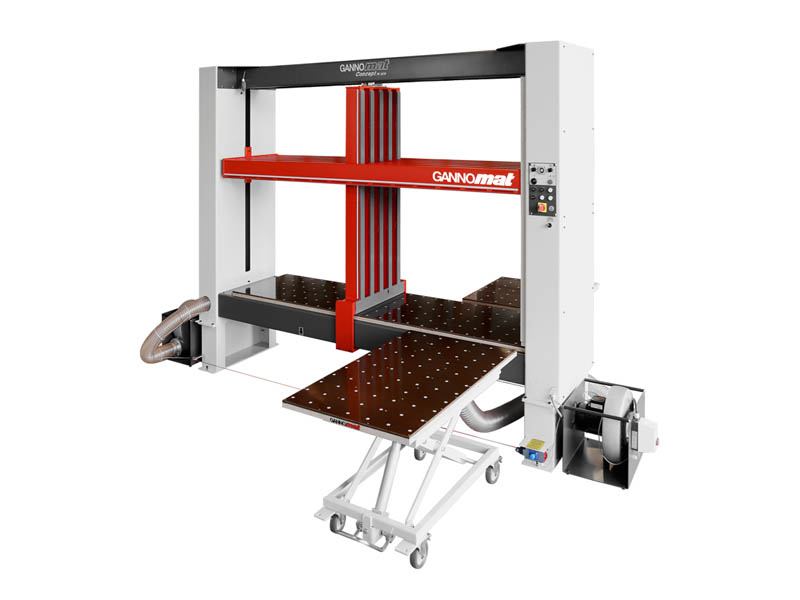

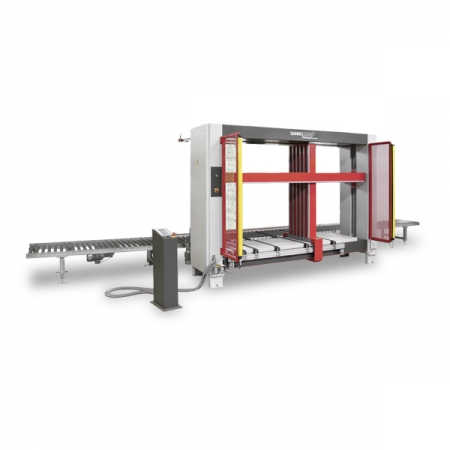

The Gannomat Concept Handling Systems can be added to any Concept case clamp as an option. Those cabinet handling systems enables a more profitable, cost saving and increase of the performance of cabinet assembly. This allows to raise the capacity of the case clamp tremendously also for large cabinets with only one employee.

Why Gannomat Concept Handling Systems?

- A wide range of handling systems are available to adapt to the Gannomat Concept series case clamps to create efficiencies

- Makes work easier (work simplification)

- Increases the quality

- Increases flexibility

- Increases the capacity (increases performance)

- Reduces set-up times and work (reducing costs)

- Optimized process

KEY ADVANTAGES

- Handling systems can be expanded and supplemented as required

- Case good handling systems enable faster and easier furniture assembly

- Higher number of pieces of furniture through case good handling systems in the final assembly line

- Increased flexibility and an alternative to through feed case clamps

OPTIONS

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.