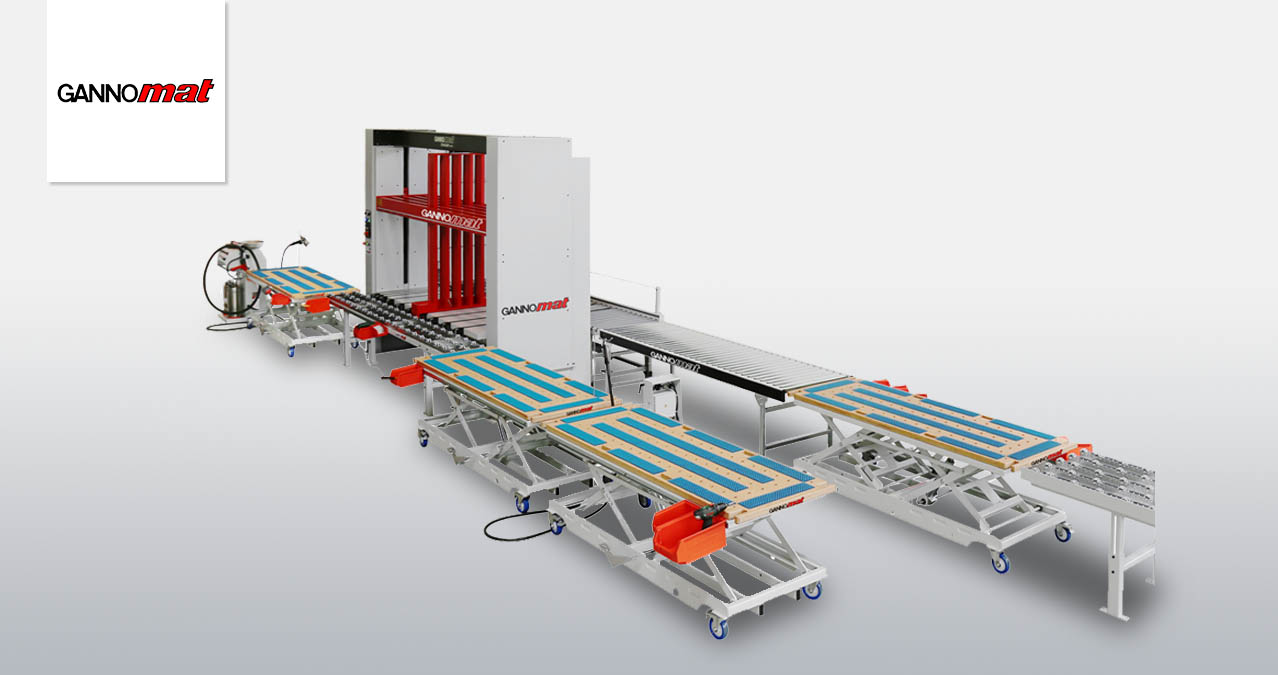

Improve your cabinet assembly times and optimize your product flow.

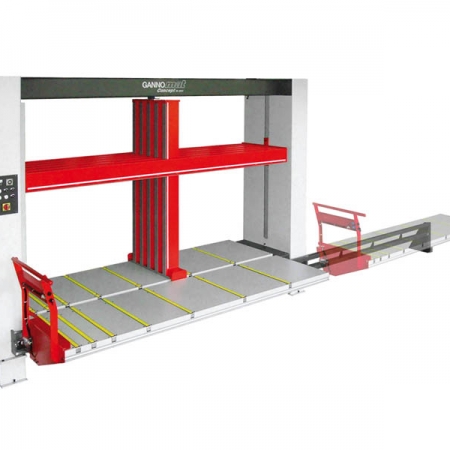

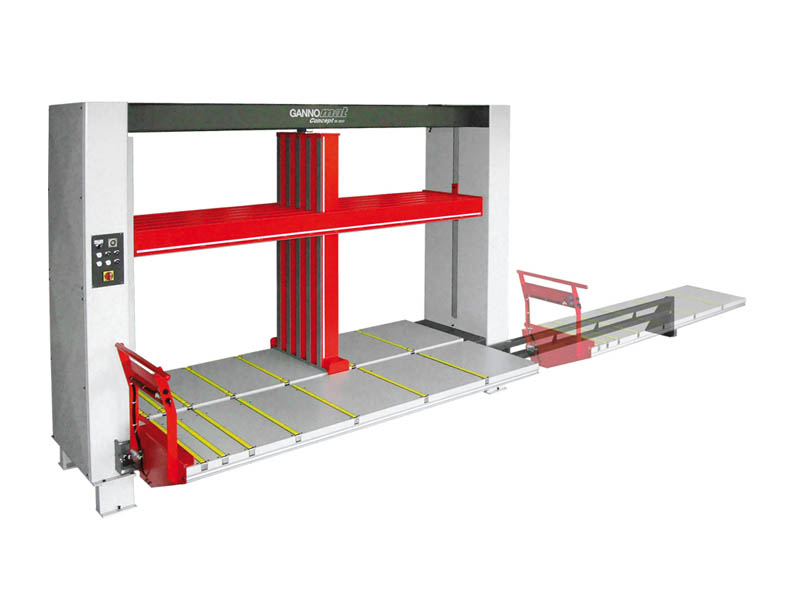

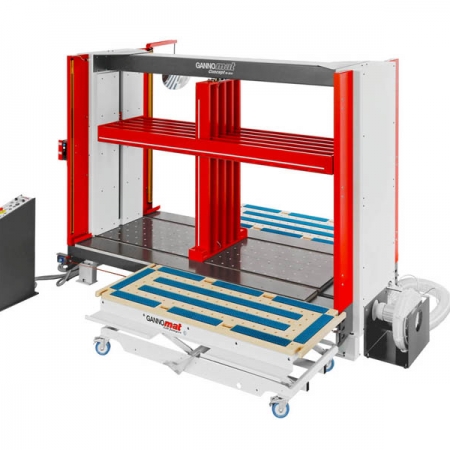

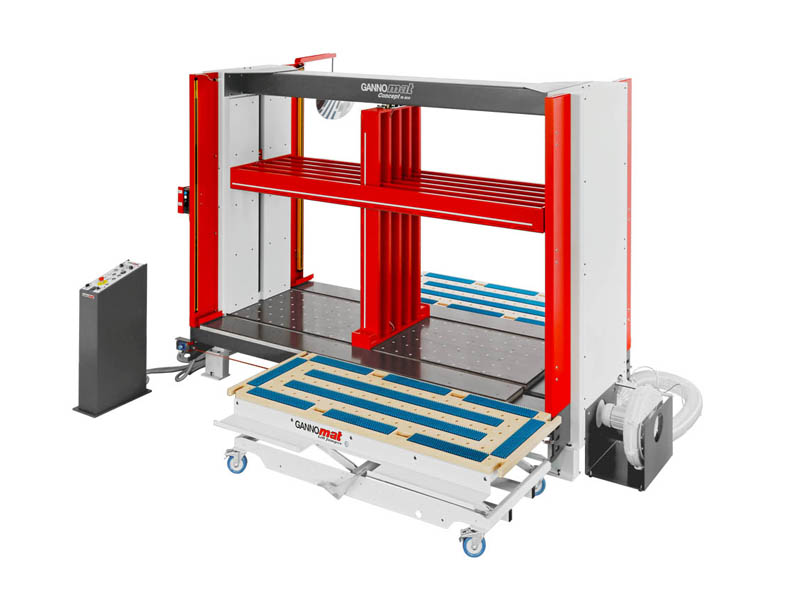

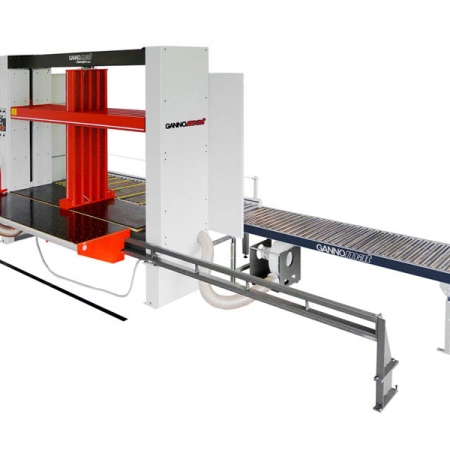

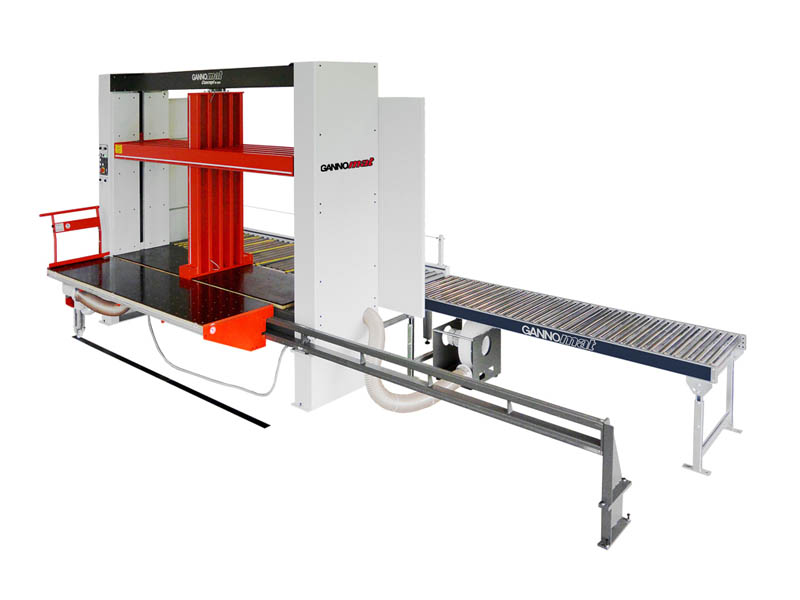

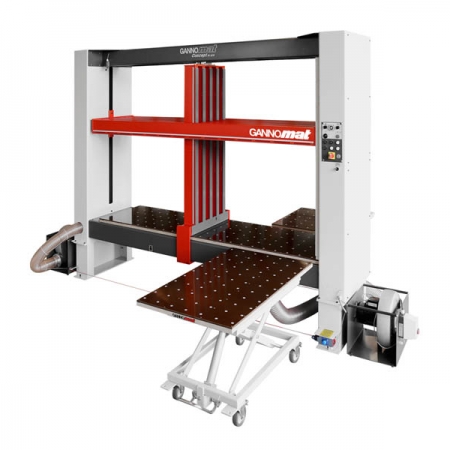

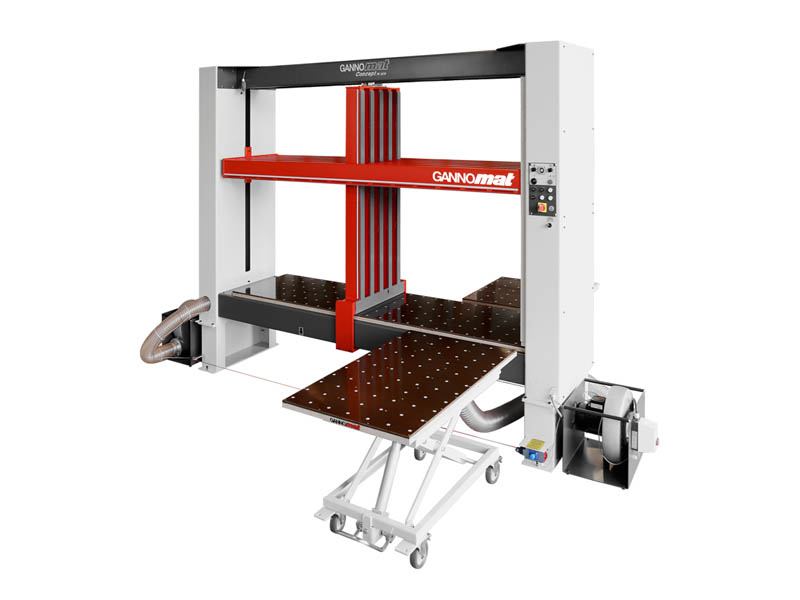

The Gannomat Concept Handling Systems can be added to any Concept case clamp as an option. Those cabinet handling systems enables a more profitable, cost saving and increase of the performance of cabinet assembly. This allows to raise the capacity of the case clamp tremendously also for large cabinets with only one employee.

Why Gannomat Concept Handling Systems?

- A wide range of handling systems are available to adapt to the Gannomat Concept series case clamps to create efficiencies

- Makes work easier (work simplification)

- Increases the quality

- Increases flexibility

- Increases the capacity (increases performance)

- Reduces set-up times and work (reducing costs)

- Optimized process

KEY ADVANTAGES

- Handling systems can be expanded and supplemented as required

- Case good handling systems enable faster and easier furniture assembly

- Higher number of pieces of furniture through case good handling systems in the final assembly line

- Increased flexibility and an alternative to through feed case clamps

OPTIONS

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.