Productivity, Performance, Process, Profit.

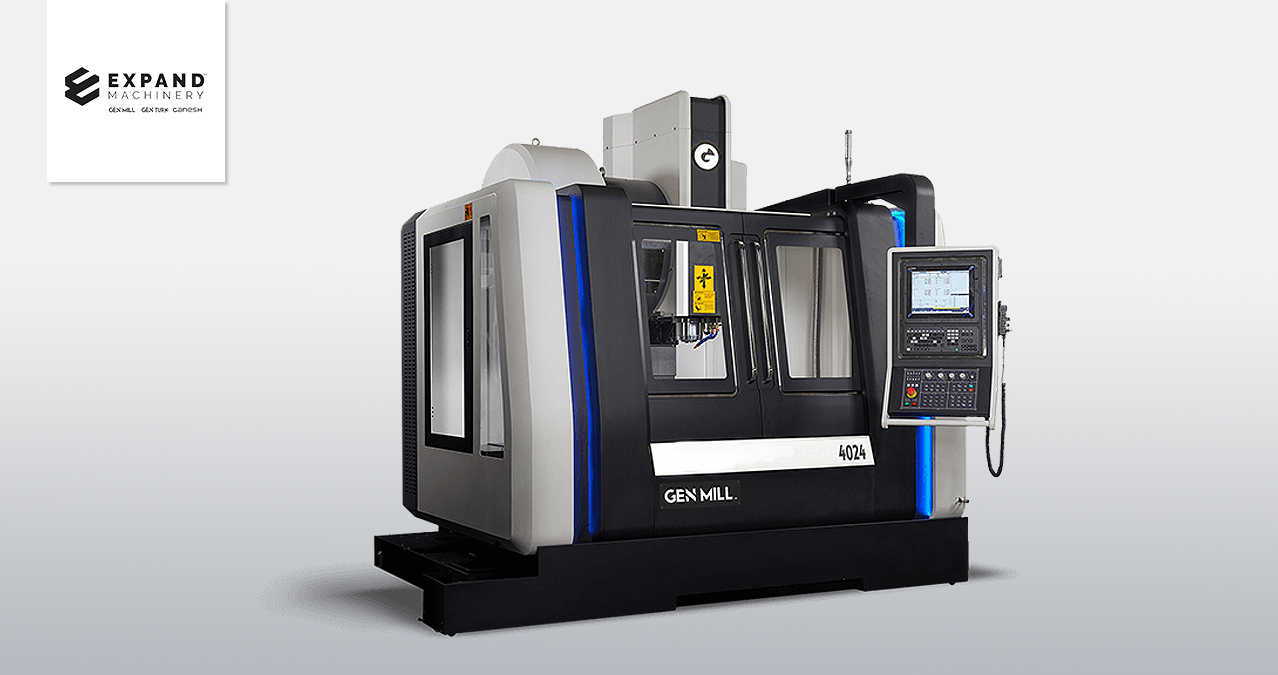

The Expand Machinery GENMILL 4024 High Speed CNC Machining Center combines strength with speed for optimum productivity, and features travels of 40.5” in X, 23.6” in Y, and 25.6” in the Z-axis. The rigidity of the massive Meehanite processed cast iron frame provides a high-strength cutting platform with superior vibration dampening and efficient metal removal rates.

Why Expand Machinery GENMILL 4024 High Speed CNC Machining Center?

- 30 Tool High Speed Double Arm ATC

- 1,417 Inch per Minute Rapid Rates

- Spindle Chiller for Consistent Thermal Stability

- 300-PSI Through-the-Tool Coolant System

- 2,700 Block Look-Ahead High-Speed Machining

- 4th & 5th Axis Wiring

- Mitsubishi M830 control features high-speed machining and includes super smooth surface control to provide superior surface finish

- Combination of the high speed machining features in the M830 and the enhanced metal cutting attributes of the high performance Big-Plus spindle and other listed enhanced machine characteristics combine to create a more productive metal removal environment

STANDARD FEATURES

- The 12,000 RPM 25-HP direct-drive in-line #40 taper spindle features rigid-tapping and includes a thermostatically controlled spindle-oil cooler.

- The dual-contact precision ground “Big-Plus” spindle provides enhanced rigidity, superior concentricity, increased tool life and greater cutting capability; along with excellent tool length repeatability.

- Precision pretensioned roller bearing guideways to provide nearly twice the rigidity of ball bearing ways for enhanced cutting performance and the 1,417 IPM rapid rates make for reduced cycle times.

- A fast 1.7-second tool-to-tool change time is combined with a 30-tool twin-arm automatic tool changer.

- An included 300-PSI through-the-tool coolant system is also included for more efficient chip removal and extended tool life.

- A host of helpful standard features that others charge extra for are included with the machine.

SPECIFICATIONS

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.