Machine Information

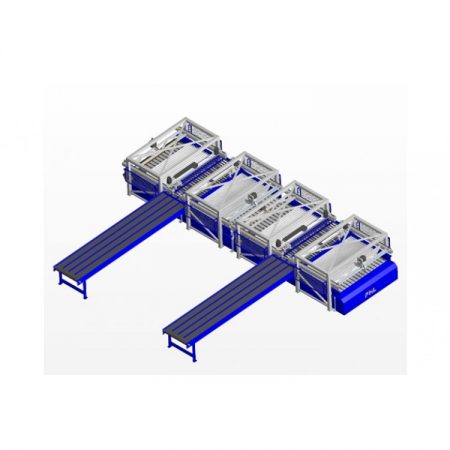

The model END PRO is a compact End-Matcher requiring minimum floor area.

The End Pro Model allows short custom orders to be handled profitably, material as short as 6″ and up to any length to be processed and pre-finished flooring to be end-matched. It handles materials up to 12″ wide.

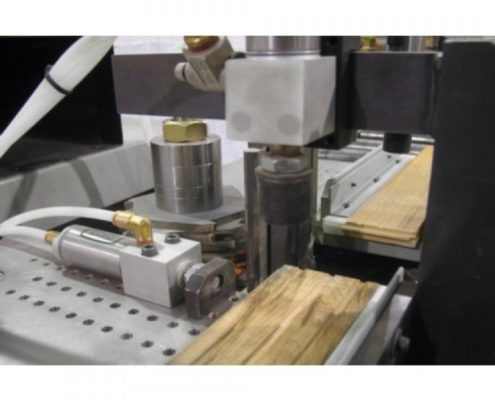

End-matching is accomplished by stacking both the tongue and groove cutters on the spindle, and by setting the infeed table to the working height of the top cutter and the outfeed table to the height of the lower cutter. As the board enters the machine, the tongue is machined onto the leading end of the board. As the board exits, the groove is cut into the tail end. A simple, compact and efficient approach to end-matching random length materials.