Protect your product for transport without taking a lot of time to do it.

The Dynawrap PRO Series Orbital Wrappers are packaging machines that consist of a welding unit of bubble film or PE film and a horizontal wrapping unit applying stretch film. The packaging process is performed in one phase as the stretch film application surrounds the product leaving the package fully protected on all edges.

Packaging used to be considered a no value offer for many manufacturers however today customers put a great value on receiving their goods without transport damage. Whether you are working in the cabinetry industry or are a door manufacturer protecting your valuable product for shipment saves time when parts need to be rebuilt or reworked and ultimately results in more satisfied customers.

The Dynawrap Pro series orbital wrappers are the ideal automated packaging solution to speed up throughput and reduce defects.

Why Dynawrap Pro Series Orbital Wrappers?

Robustness Finds Its Body.

The New Dynawrap orbital wrapper is strong and robust with new design and chassis. Manufactured by high quality steel and alloys creating a body which will work for long years and offers you a reliable packaging every single day.

Compact Design Fits Everywhere.

Thanks to the new compact design, Dynawrap fits everywhere. You do not need to worry for the space. Reduced side curves and folding additional plate inside the crown makes a bigger diameter in a smaller space. If needed it can be combined with shorter conveyor longer depending on the customer needs and makes always the perfect packaging.

Versatile Solutions Today and Tomorrow.

Dynawrap Pro is the most versatile Orbital Stretch Wrapper in the market. Considering that customer demand may vary anytime for any manufacturer, Dynawrap offers a “2 in 1” or “3 in 1” machine. It can be combined with Pro Air Bubble or Pro Shrink type anytime you want. In this respect it is the only product in the market offering the most versatile solutions.

Performance Meets with Technology and Velocity.

Fully automatic models equipped with the latest technology and powerful mechanical powertrain design offers the best performance. Easy remote diagnose, USB and reporting are available in all standard models. Wifi, Industry 4.0 and mobile controls are the optional features for Dynawrap. Moreover, it has the highest crown rotation speed and shortest wrapping time in the market. A better machine is always the best idea.

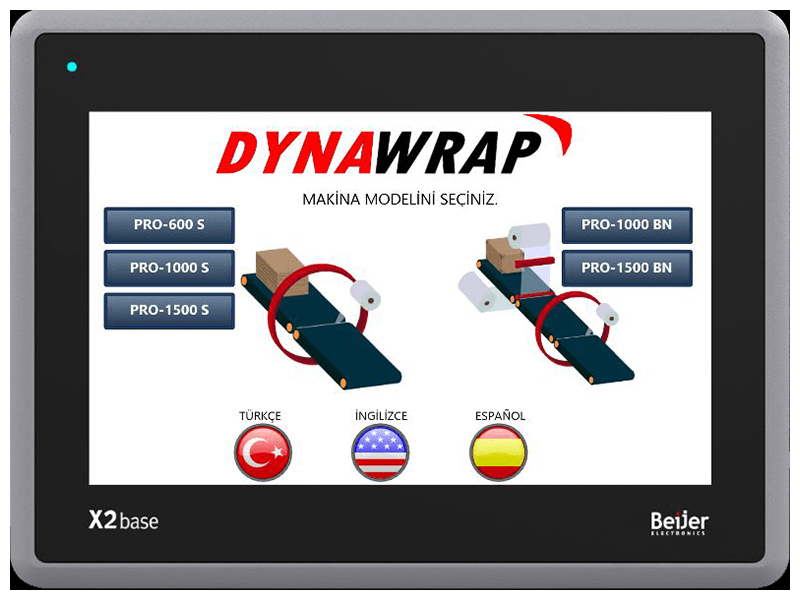

User Friendly. Smart Panel Control.

Dynawrap Pro models are equipped with 7″ Beijer Smart Panel and our fast-working interface makes the operators life very easy and creates a user-friendly platform. Beijer Panel together with Beijer drivers ensures high-speed responding to the machine. Creating a recipe and saving recalling takes less than 10 seconds. You can get your daily report to your USB or by ftp connection.

Easy and Quick Assembly.

Introducing a compact machine created by Dynawrap that delivers a higher strength, easier and faster assembly. Once you receive your machine, it already comes assembled. Bolted solutions make for easier serviceability and quick part replacement if needed.

- Automatic stretch film clamping and cutting unit

- Stretch film rolls stock rack

- Automatic infeed and outfeed pressure rollers (can be set on or off as needed)

- Motorized infeed and outfeed conveyors with anti slip type green belt

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.