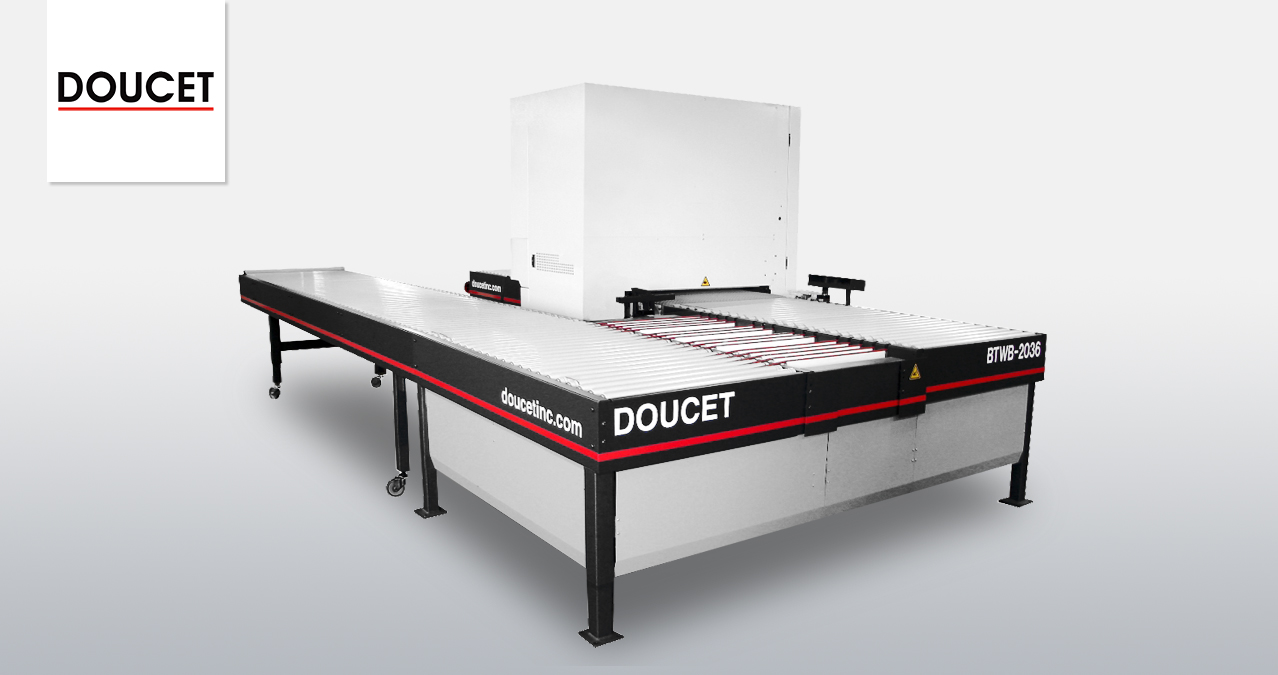

The fast, simple and highly effective belt transfer return conveyor system and perfect companion for your wide belt sander.

Built around a modular frame, the Doucet BTWB3 Widebelt Sander Return Conveyor is available in 5 roller length models, BTWB3-24, 30, 36, 48 and 60. All models incorporate the fast, simple and highly effective belt transfer system as follows.

Why Doucet BTWB3 Widebelt Sander Return Conveyor?

- Operate a wide belt sander with a single operator

- Reduce opportunity for damage to your finished product due to mishandling

- Available in working widths from 24” up to 60” wide

- Customizable to suit your production needs and machine configuration

- Available in either left- or right-hand return allowing for proper access to sander for belt changes and maintenance

- Variable speed receiving conveyor can be matched to your sander feed speed

- Return conveyor mounted on casters with quick disconnection to allow for easy access to the sanding machine

OPERATING PRINCIPLE

Its receiving rollers are equipped with a down stroke mechanism that is activated by detection of the trailing end of the panels exiting the equipment. Transfer belts nested in between the rollers are used to side-shift product to a set of motorized rollers parallel to your equipment. Once the panels have cleared the reception area, the receiving rollers return to their upper position ready to receive the next panel. Its standard receiving and return conveyor lengths are 5′ and 15′ respectively. Both sets of rollers can be extended to suit your application.

OPERATING SPEED

BTWB3 Return Conveyors are equipped with a variable speed drive to match the processing speed of your equipment, receiving table speed is adjustable from 30 to 90 ft/min, belt transfer speed is fixed at 90 ft/min and return conveyor speed is adjustable from 30 to 90 feet/min.

DIRECTION OF RETURN

According to your indications, BTWB3 Return Conveyors are built for right or left-handed return. However, they remain adaptable to your changing needs throughout their useful life as transfer and return orientation can be field modified from right-hand to left-hand and vice-versa.

One Anderson.

Corporate, Machinery SolutionsAkhurst has made the move to distribute all of Anderson’s machines under one brand, Anderson. Anderson is the world leading CNC router manufacturer, with over 20 thousand machines sold worldwide and 5 thousand only in the US market.

When does pre-milling make sense?

Machinery Solutions, Service and SupportOver the past few years, pre-milling has grown in popularity. Pre-milling is the process of machining the edge of the panel prior to applying glue. It ensures optimal edge quality before the application of edge banding, resulting in reduced glue joints and a highly aesthetic edge.

Visit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Corporate, Machinery Solutions, Trade ShowsThe WTD is back with extended dates, now giving visitors five days to visit our members’ extensive showrooms and see the latest new technology, including some North American premieres. No other show or single event offers you such a wide display of woodworking equipment, combined with impressive live demonstrations at each location.