Stop wasting talent on the back end of your edgebander

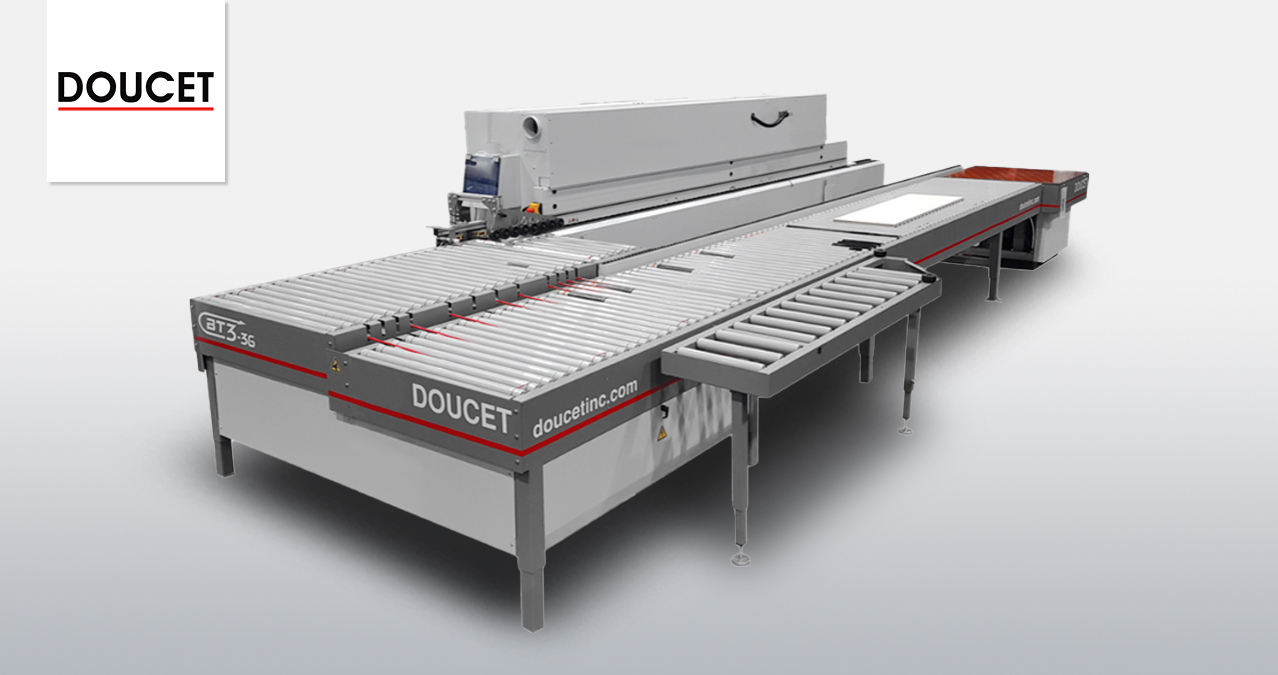

Streamline your edgebanding operations with a DOUCET BT3 return conveyor. The addition of a BT3 return conveyor can increase productivity and efficiency while adding more to your bottom line.

Why Doucet BT3 Edgebander Return Conveyor?

- One Edgebander + One BT3 Return Conveyor = One fully productive operator, a streamlined workflow, less handling damage, less rejects

- Single operator required to load and unload panels from an edgebander

- Less rejects due to damage from handling

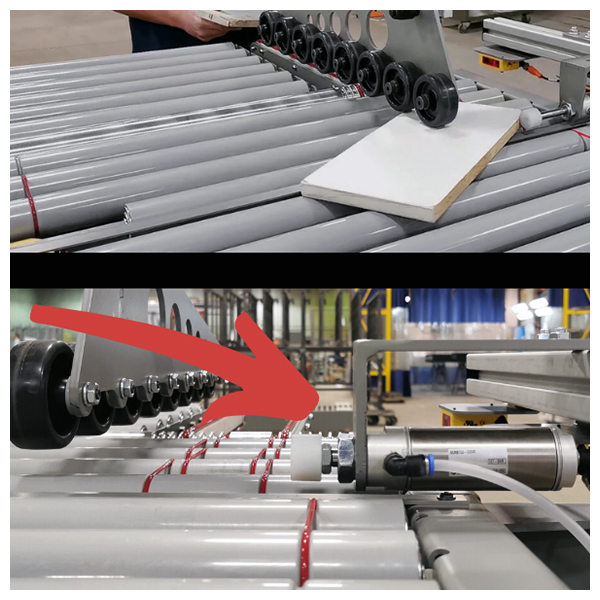

- Parts that require rework are returned directly to the infeed of the edgebander

KEY ADVANTAGES

- Various widths available to suit your part dimensions:

- BT3-24, BT3-30 and BT3-36’s are ideal for most case good applications, such as kitchen & bathroom cabinets and living room furniture.

- BT3-48 and BT3-60 conveyors are best suited for surface finishing applications, such as office furniture and display casings

- Available with right-hand or left-hand return, according to your model of edgebander

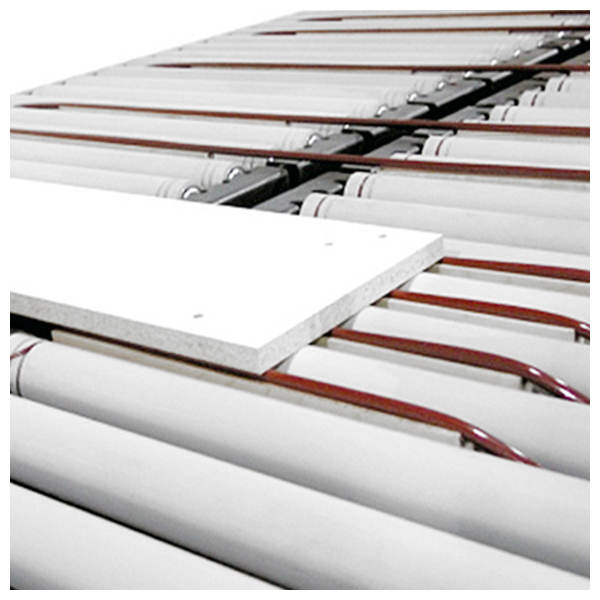

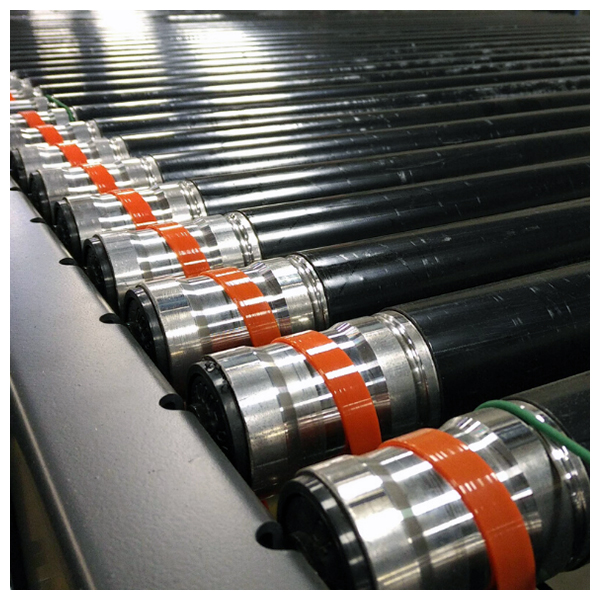

- Non-marking urethane rollers

- Variable speed drive to match the speed of your edgebander

- Adjustable return speed

High-end cabinetry, movie stars, Marvel has it all.

Case Study, Corporate, Machinery Solutions, Service and SupportMarvel Cabinetry, from De Winton, AB, is the exclusive cabinetry supplier for the first and second seasons of Property Brothers’ Celebrity IOU on HGTV, and has designed and built made-in-Canada cabinetry for stars across North America. Among them were Michael Bublé, Brad Pitt, Snoop Dogg, Gwyneth Paltrow, Melissa McCarthy, Viola Davis, Jeremy Renner, Kevin Hart, Howie Mandel, and LeAnn Rimes, and Marvel invites you to be next.

Achieving optimum performance from your edgebander.

Service and SupportEdgebanders tend to be one of the more complex machines to operate in a woodworking shop, and their performance has a vital impact on the quality of your finished product. Proper machine setup, maintenance, and cleaning play a major role in achieving the best edgebanding results. Below are some basic tips that can greatly reduce the downtime you experience on your edgebander and keep it producing quality components.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.