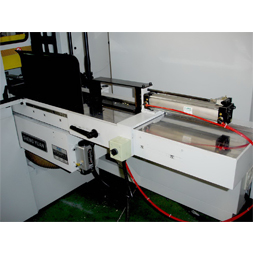

Increase the loading efficiency of your CNC router or panel saw with the safe and versatile handling arm from Delaney.

The Delaney VL Series Vacuum lifts are handling arms that are adaptable to any workstation requiring lifting of heavy and/or cumbersome loads. The system is entirely pneumatic and does not require power or a noisy vacuum pump. Available in a range of lifting capacities, heights, and lengths to suit your handling needs. What would normally require multiple people to lift is done with ease on the Delaney vacuum lift. With the capacity to rotate 360 degrees around the column there are virtually no limitations with this device.

Why Delaney VL Series Vacuum Lifts?

- Entirely pneumatic

- Improves safety and productivity

- Quick return on your investment

- No maintenance required

- Does not obstruct your line of sight

- Anchoring takes up less than 2 sq ft of floor space

- Fifteen times faster than an electric hoist

- Independent of the building structure

- Quiet and does not dissipate heat

- Can cover a work area of 450 sq ft or more

- Can rotate 360º around the column

- Quiet, safe, entirely air powered, no maintenance required

Lifting capacity |

100 – 3000 Lbs |

Beam (arm) length |

12 ft – 22 ft |

Column height |

8 ft – 22 ft |

Vertical stroke |

44″ (variable on request) |

Requirements |

Air (min. 100 PSI) (.16 CFM) |

Rotation of beam around column |

360o |

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.