Industrial oscillating edge sander for the most demanding of jobs.

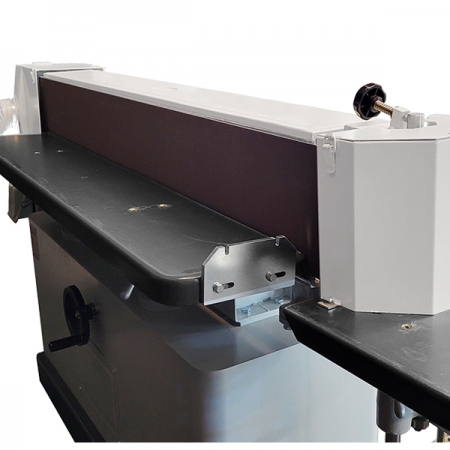

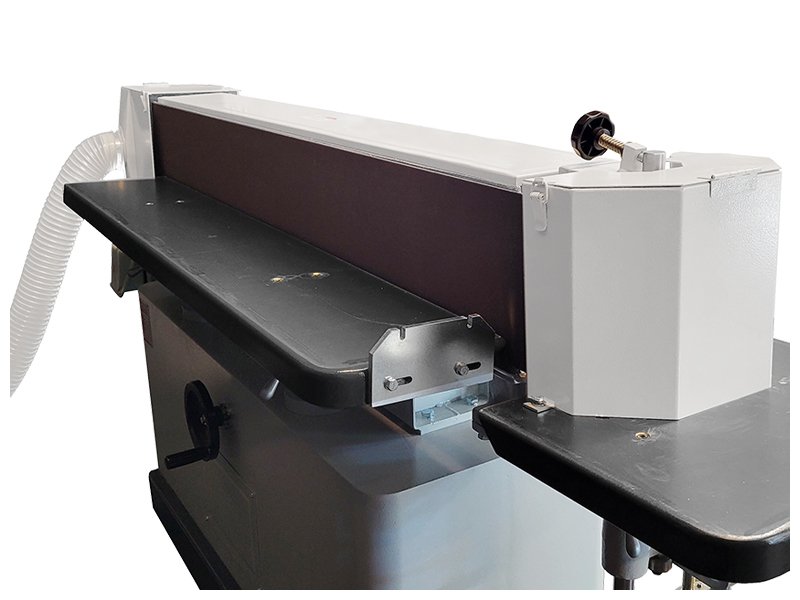

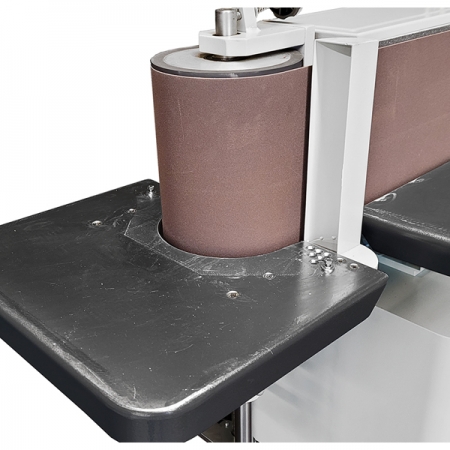

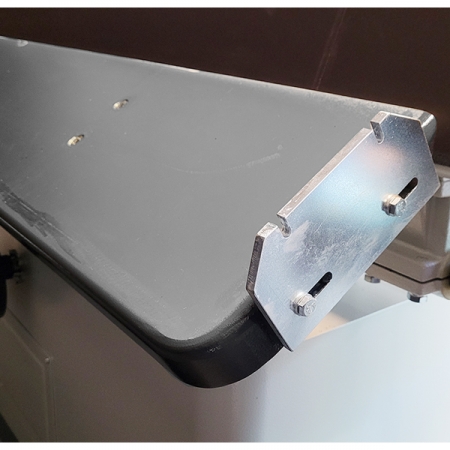

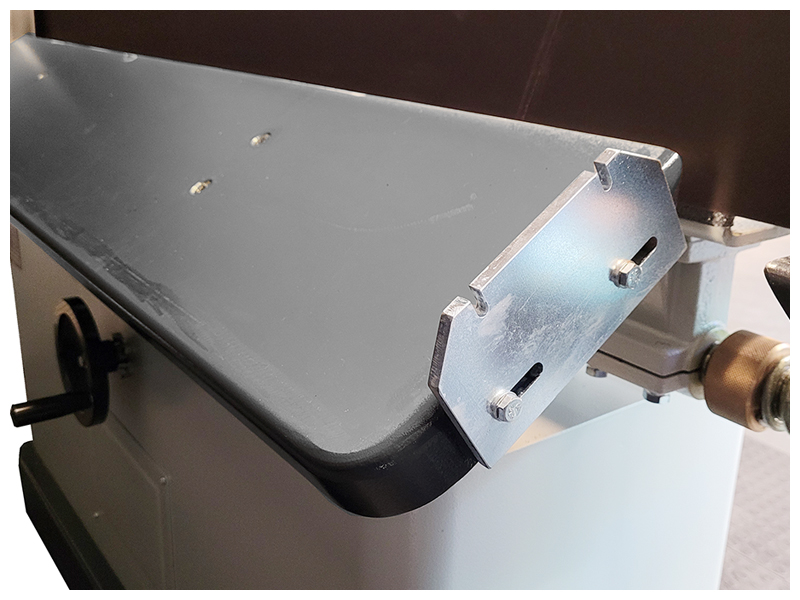

The Cantek OES512D Heavy Duty Oscillating Edge Sander is the ideal edge sander for demanding applications for production use. Equipped with a 12” high oscillating sanding belt, it is ideal for sanding drawer boxes, doors, furniture components and more. The OES512D is also equipped with dual front and rear tables which are adjustable up & down and can be tilted to 45 degrees, allowing for a wide range of applications and full utilization of the sanding belt. The dual tables also allow for two operators to be working on the machine at the same time made possible by the powerful 10 HP sanding motor. The adjustable and tiltable end table allows for sanding of curved components on the idle pulley. The belt oscillates up and down which helps in keeping it cool while also producing an optimum sanded finish.

Why Cantek OES512D Heavy Duty Oscillating Edge Sander ?

- Heavy-duty design with powerful 10HP driving motor offers high efficiency in production environments

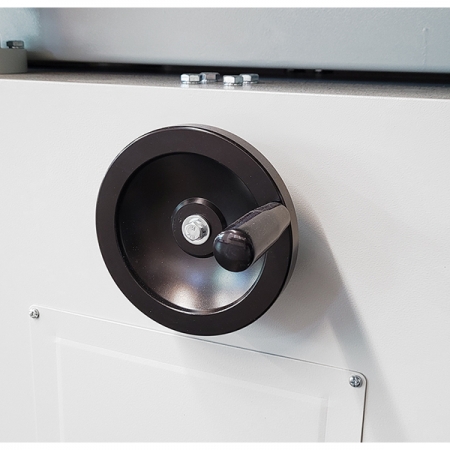

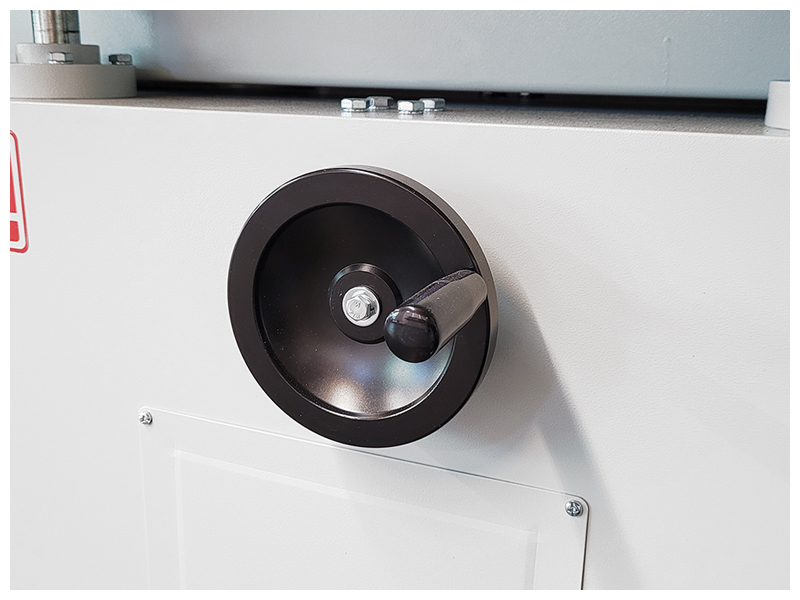

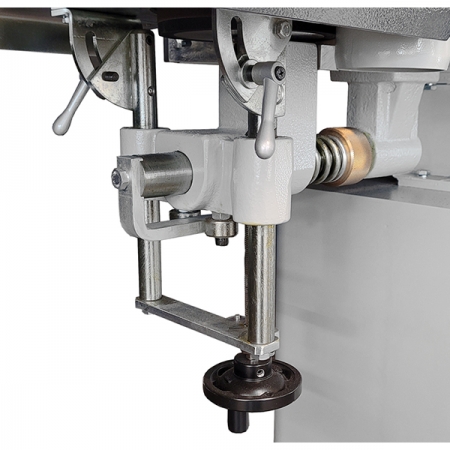

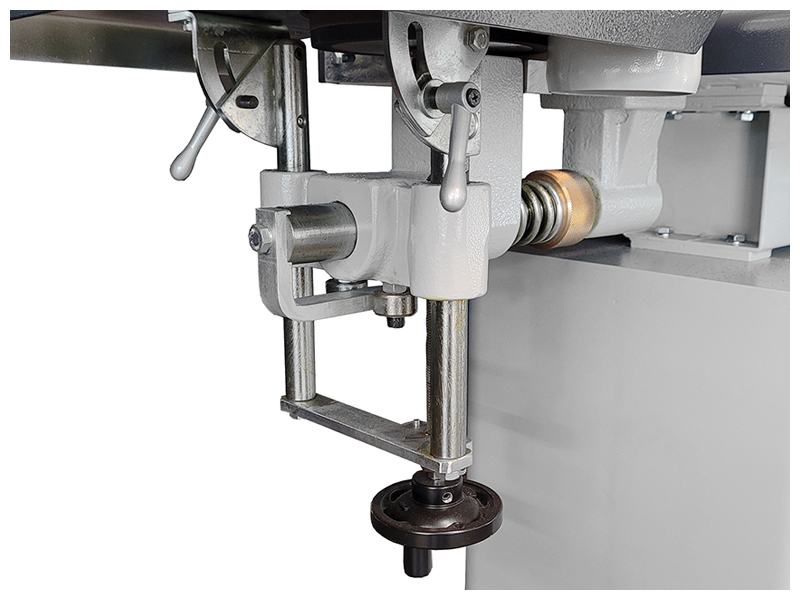

- Front, back and side tables are adjustable in height by handwheel and can be tilted for bevel sanding operations

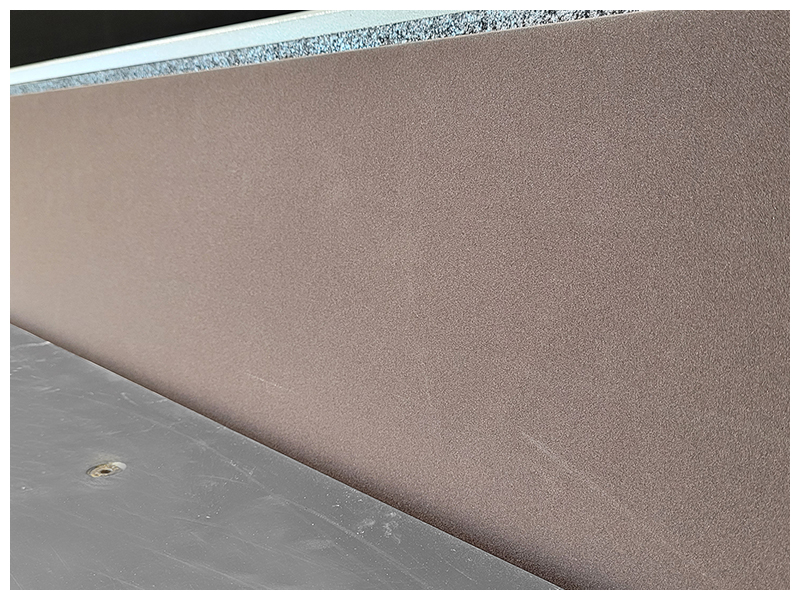

- Oscillating sanding belt for optimum sanding results

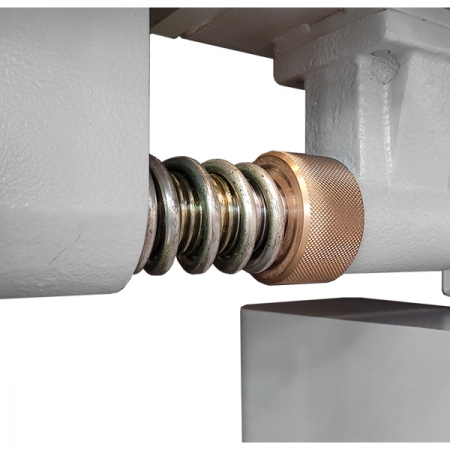

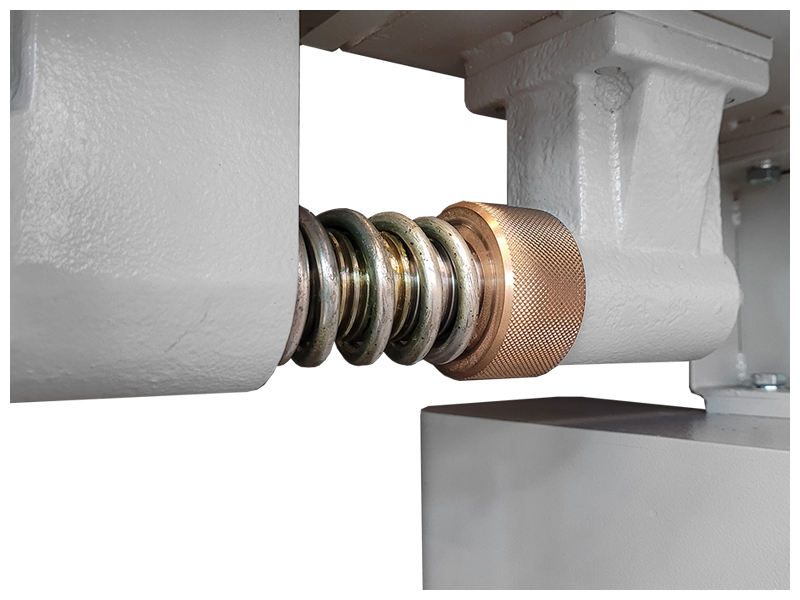

- Quick belt change with adjustable belt tension

- Side table can be used for sanding the curve style work pieces.

- Built of heavy welded plate steel for rugged base construction and vibration free sanding

- Belt oscillation by gear reducer

- 12” x 166” sanding belt

- Front and rear sanding platens are covered with anti-friction graphite cloth

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.