Designed for consistency, ease of use, and excellent finished results.

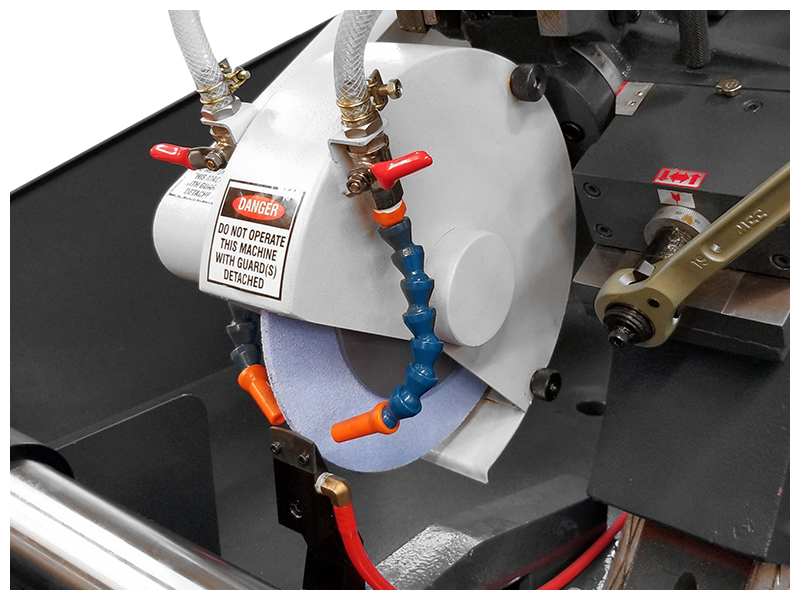

The Cantek JF330A Profile Grinder was designed to ensure the operator can produce an optimum knife finish, while producing precisely accurate profiles. The powerful 3HP grinding motor makes knife grinding a breeze. The VFD allows the operator to dial in the optimum grinding speed no matter what type of knife steel they are grinding. Using an axial constant setup, tools can be transferred to the moulder quickly for precise and fast changeovers. The cutterhead is mounted to a sliding worktable which runs on high precision Schneeberger linear bearings. All these special features make the JF330 profile grinder the ideal solution for the small to large size moulding shop.

Why Cantek JF330A Profile Grinder?

- Powerful 3 HP grinding motor, allowing deep aggressive grinding when required.

- Axial constant set up, allowing the ground tools to be easily transferred to the moulder for quick changeover

- Stainless steel splash guards, coolant tank for long rust-free life

- Easy to access adjustments and controls

- 3 HP grinding motor

- VFD to allow RPM to be varied for different wheels, and diameters

- Schneeberger linear bearings for effortless and smooth worktable movement

- Axial constant set up

- Quick change side angle adjustments

- Quick change grinding wheel hubs

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.