It is time to upgrade your cabinetry with precision dovetail drawer boxes.

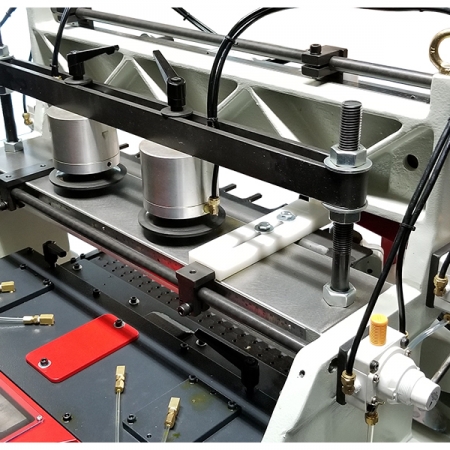

Add prestige to your cabinets with aesthetically pleasing dovetail drawer boxes with Cantek JDT75 Automatic Dovetailer. Dovetails display your quality and are built to last, producing beautifully aesthetic dovetails for drawer box production from a wide range of wood types, including plywood and solid wood. This fully automatic machine produces both the pin and tail of the dovetail simultaneously. All four sides of the drawer can be loaded into the machine for optimum production capacity.

Why Cantek JDT75 Automatic Dovetailer?

- High-quality finish in both plywood and solid wood drawer box material

- Fast operation with up to 40 drawer boxes produced in an hour

- Solid cast iron machine structure for vibration-free dovetailing leading to a long machine life

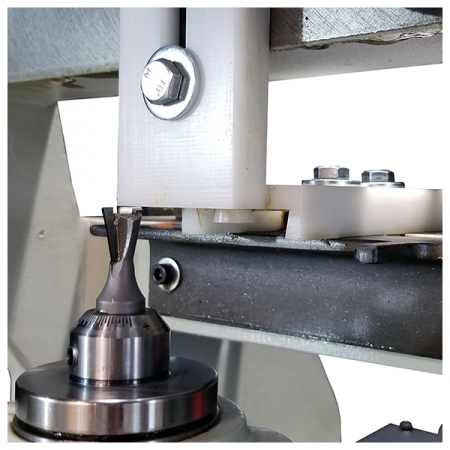

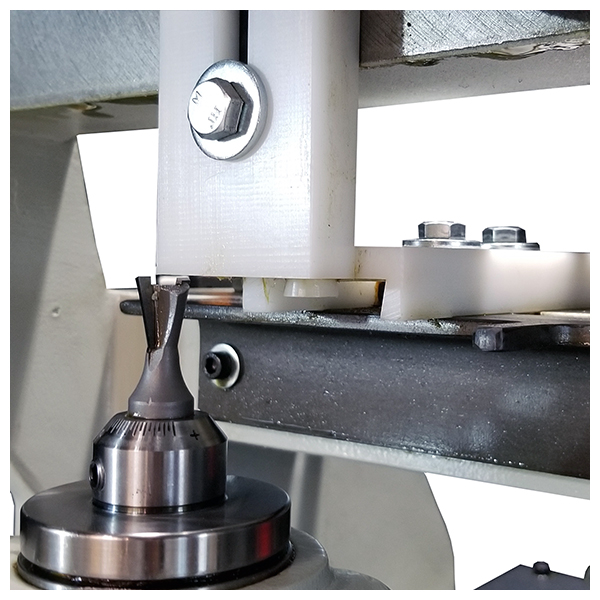

- Superior finish with two flute dovetail bit

KEY FEATURES

- 21500 RPM spindle for an extremely fine finish on dovetail joints

- Independent adjustment of both the tenon & the mortise depth for precise fitting of dovetail joints

- Cast iron base to ensure vibration free cutting

- Pneumatic clamping for fast component changeover

- (3) cycle speeds for best finish results

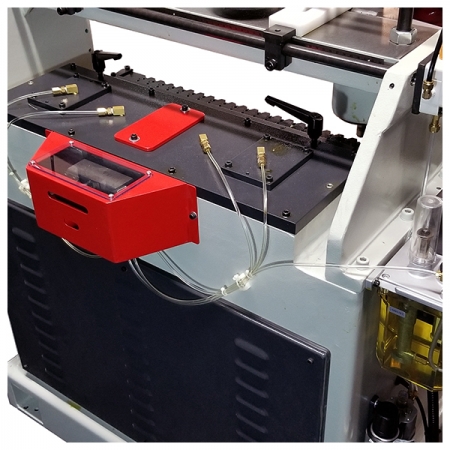

- Automatic lubrication system to spindle stroke

- Dust hood for milling cutter

- Safety rail in front of spindle motor

- Straight or spiral dovetail bits available

SPECIFICATIONS

OPTIONAL EQUIPMENT

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.