Cut with confidence and accuracy.

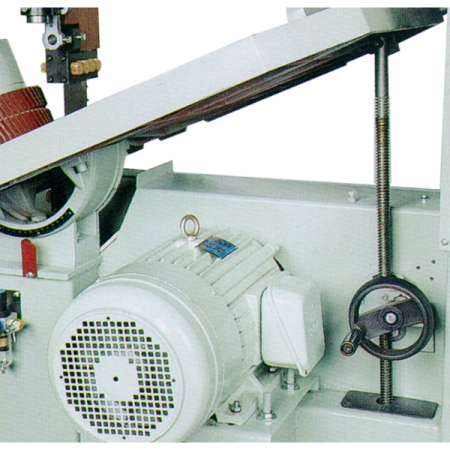

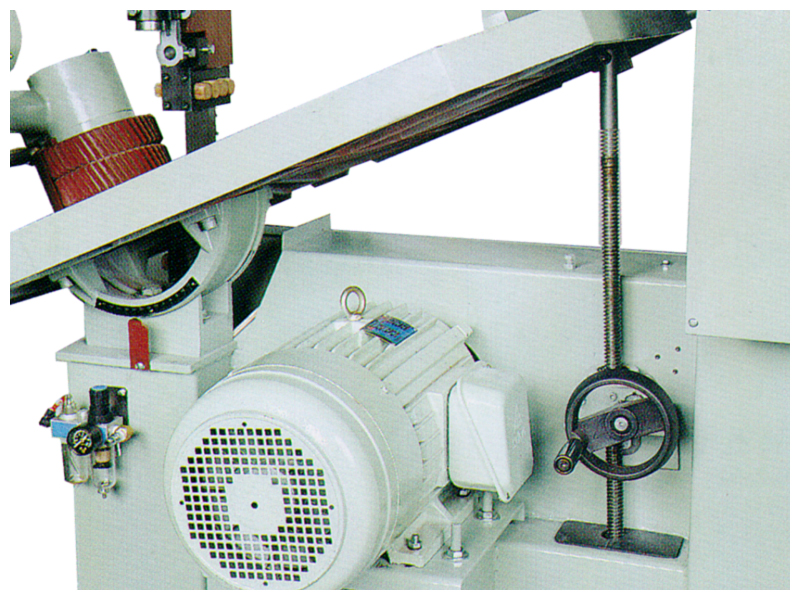

The Cantek HB800 32” Band Resaw with Feeder is built to last. A 4” wide blade is driven by a powerful 20HP motor for precision straight resawing. Equipped with a 1HP power variable speed feed unit which is pneumatically actuated to provide consistent feeding of the workpiece. The feed speed can be variably adjusted from 3 to 56 FPM in accordance with the material type and thickness.

Why Cantek HB800 32″ Band Resaw with Feeder?

- Cast iron upper and lower saw wheels are precision machined and dynamically balanced

- Powerful 20HP saw motor

- 4” wide resaw blade for precise straight resaw cutting

- Specially designed Bakelite guide blocks provide rigid side blade support for straight cutting

- 1HP infinitely variable speed feeder with feed speeds from 3~56 FPM ensures consistent feeding of work pieces during resawing operations

- Feeder is pneumatically actuated by a foot pedal for operator convenience

- Adjustable roller infeed fence to facilitate with feeding of the workpiece

- Upper and lower Bakelite guides ensure blade stability for optimum cutting results

KEY ADVANTAGES

- Heavy fabricated steel machine frame

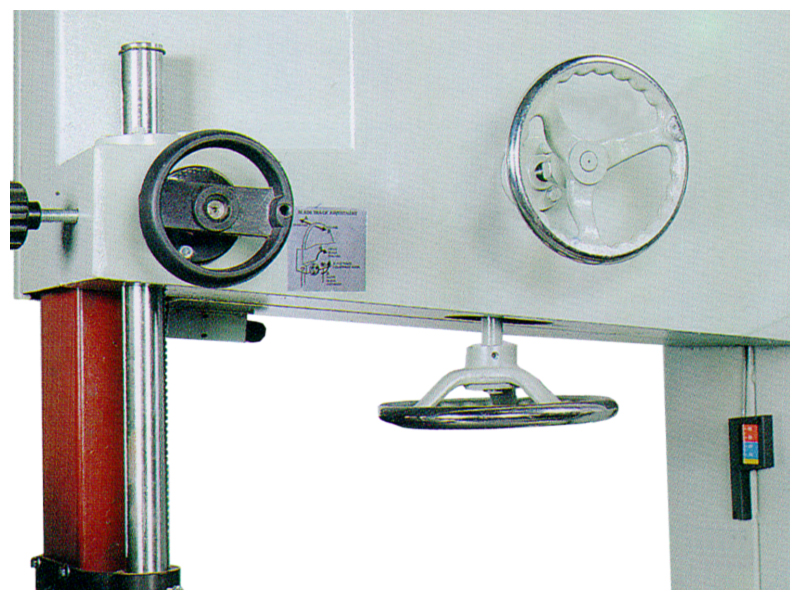

- Large cast iron worktable is precision ground and can tilt to a maximum of 45o

- Convenient spring blade tension adjustment by means of a handwheel and gauge

- Foot brake for braking wheels and blade

- Rack & pinion blade guide adjustment

- Band wheel is crowned for proper blade tracking and added stability of the blade

- Blade lubrication system and reservoir for lubricant keeps blades cool

- Auto Start-Delta control for main motor with emergency stop switch

- Feed pressure is adjustable

- Feed roller opening and closing is controlled by a foot switch for operator convenience

- Knurled steel feed roller for maximum grip

SPECIFICATIONS

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.