Consistent, safe, and powerful power feeder with the right speed for your job.

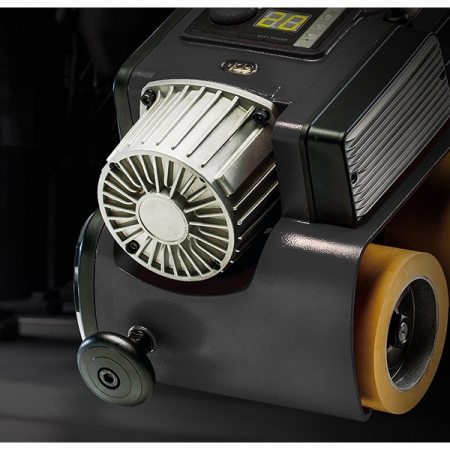

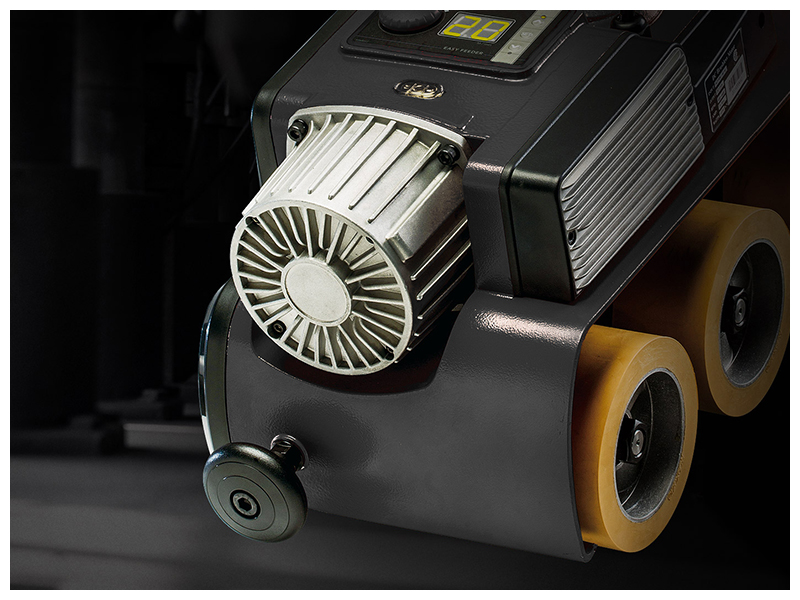

The Cantek DC30 3-Roll Variable Speed Power Feeder is a safe and powerful feeding unit for shapers, table saws, and more. The rubber feed wheels grip the workpiece firmly and feed it at a constant speed to produce flawlessly finished pieces. The DC brushless servo motor with electronic variable speed adjustment allows the operator full control for setting the optimum feed speed according to the specific job. The universal stand allows for quick positional adjustment from a horizontal to vertical positioning and everything in between.

Why Cantek DC30 3-Roll Variable Speed Power Feeder?

- High efficiency DC brushless servo motor

- High efficiency = more power, more torque!

- Saves +50% power output over other feeders of the same size

- Electronic variable feed speed adjustment for optimum cut quality

- 2/3 HP DC Brushless Servo Motor with electronic speed display

- SG13 heavy duty universal stand for fast setup

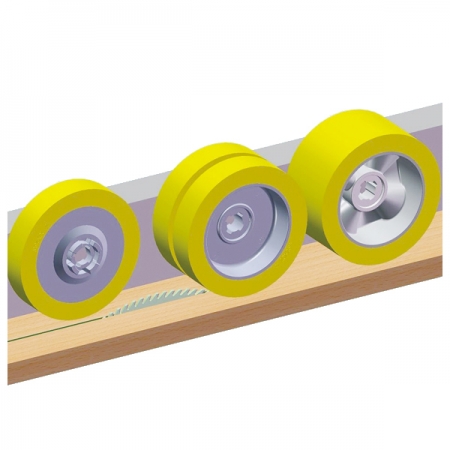

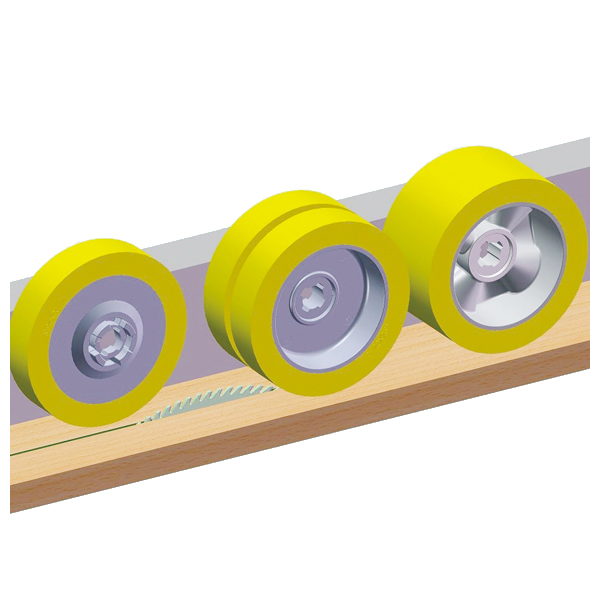

- (3) rubber feed rollers

- Variable speed 2-22 M/min (7-72 FPM)

- Forward/reverse feed

- Optional Dual Rollers for saw or cutter clearance

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.