Industrial manually operated sliding table saw for the space conscious shop.

The Cantek D405M-8 8’ Sliding Table Saw is the ideal panel cutting solution for kitchen cabinet shops, millwork companies, and furniture shops who need a precision saw but have limited floorspace. The D405M-8 combines a heavy-duty construction with cast iron main table, cast iron saw carriage, and precision sliding table resulting in precise panel sizing with high accuracy and repeatability time after time. The double roller sliding table runs effortlessly and smoothly and the crosscut miter fence can be easily and accurately adjusted for optimum results

Why Cantek D405M-8 8′ Sliding Table Saw?

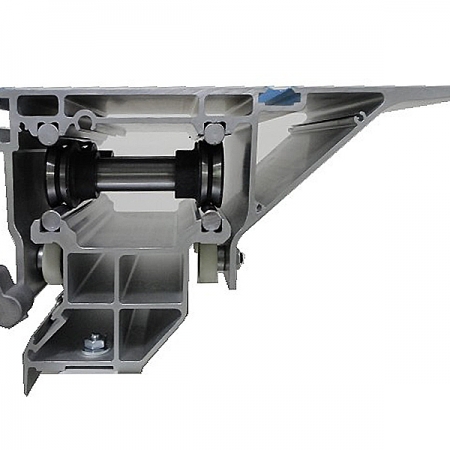

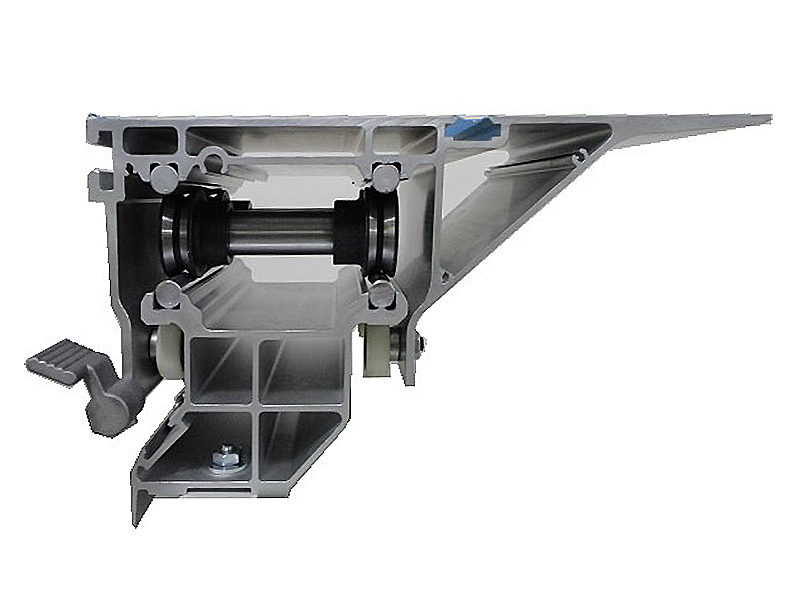

- Precision anodized aluminum sliding table with prismatic rollers running on precision ground steel guides for smooth and effortless table movement

- Crosscut miter fence with (2) flip stops for accurate panel sizing and angular cuts

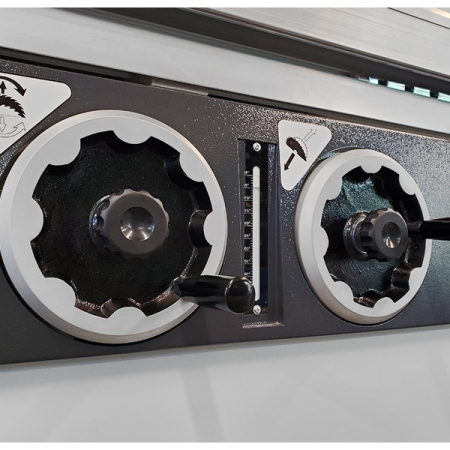

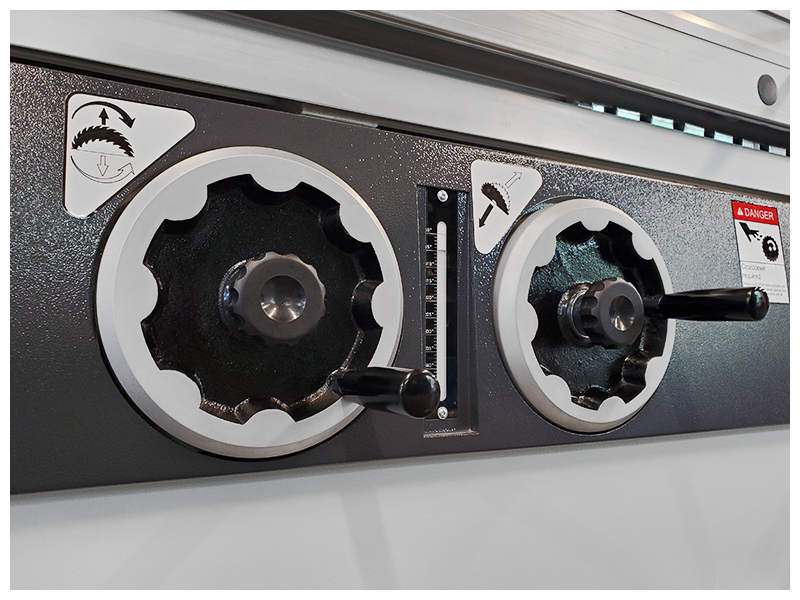

- Manual blade rise, fall, and tilting with convenient pointer for blade angle display

- Heavy duty rip fence runs on round cylindrical solid steel guide with manual adjustment and micro adjustment knob

- Overarm safety guard with quick change system for changing between straight and bevel cutting guards

- Powerful 7 ½ HP main motor for 3 Phase or 5 HP main motor for Single Phase, with separate 1 HP scoring motor

- Manual saw blade rise/fall & tilting, conveniently located on the operator side of the machine

- Heavy-duty outrigger for strong support of workpiece during cutting operations

- Dual inch and metric scales for both rip and crosscut fences

- Manual lateral and vertical scoring adjustment by externally mounted handles for operator convenience

- Eccentric hold down clamp, table return handle, and wedge for solid wood ripping included

- Overhead saw blade guard with built in dust port included (CE-type)

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.