Powered up and down blade and tilt to make it easier.

The Cantek D405A Sliding Table Saw is the ideal sliding panel saw for high accuracy cutting of sheet materials to produce kitchen cabinetry, furniture, millwork operations, and more. This is our most industrial saw with manual setting rip fence. The 10’ sliding table is made from a precision aluminum extrusion and runs on precision linear guide rails. It has motorized rise/fall and tilt of the blades.

Why Cantek D405A Sliding Table Saw?

- Motorized blade height & tilt adjustment with a digital angle readout

- Precision sliding table runs on hardened linear guides for extremely smooth and effortless movement

- Powerful 7.5 HP main motor and separate 1HP scoring motor

- Ergonomic eye level control panel for adjusting the blade height, and blade angle along with on/off switches for the main and scoring motors

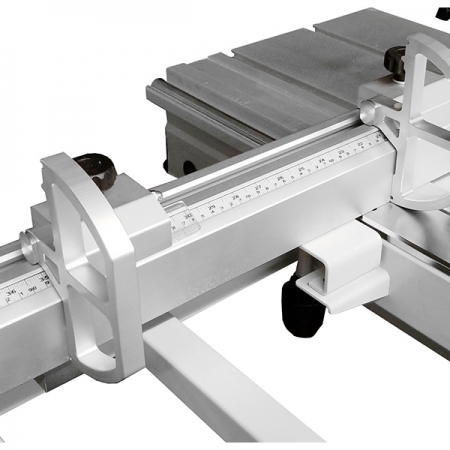

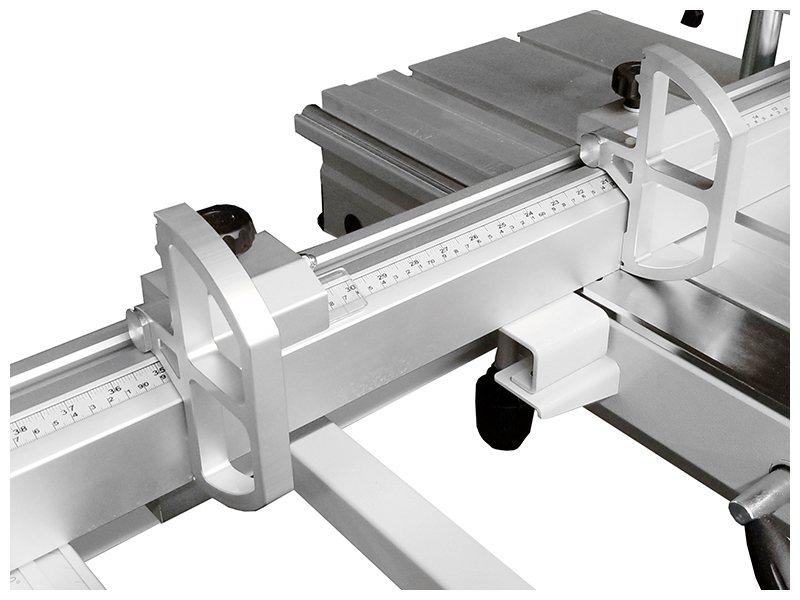

- Accurate crosscut miter fence for fast length and angle setting

KEY ADVANTAGES

- Motorized blade rise/fall

- Motorized blade tilting with electronic angle display on control panel

- Overhead control panel can be adjusted for operator convenience

- Convenient external manual scoring adjustment

- Powerful 7.5 HP main motor with separate 1HP scoring motor

- (3) saw blade speeds for optimum cutting results in various materials

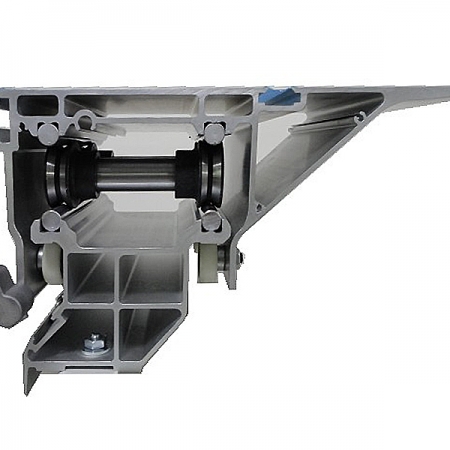

- Precision anodized aluminum sliding table with prismatic rollers running on precision ground steel guides

- Aluminum extruded crosscut fence with (2) flip stops with convenient angle adjustment for mitre cuts

- Solid cast iron main table which is ground and polished

- Heavy-duty outrigger for strong support of workpiece during cutting operations

- Overhead CE blade guard with dust port

- Complete with eccentric clamp and wedge for solid wood cutting

SPECIFICATIONS

OPTIONS

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.