An economical and high-speed approach to defect cross-cutting with partial optimization.

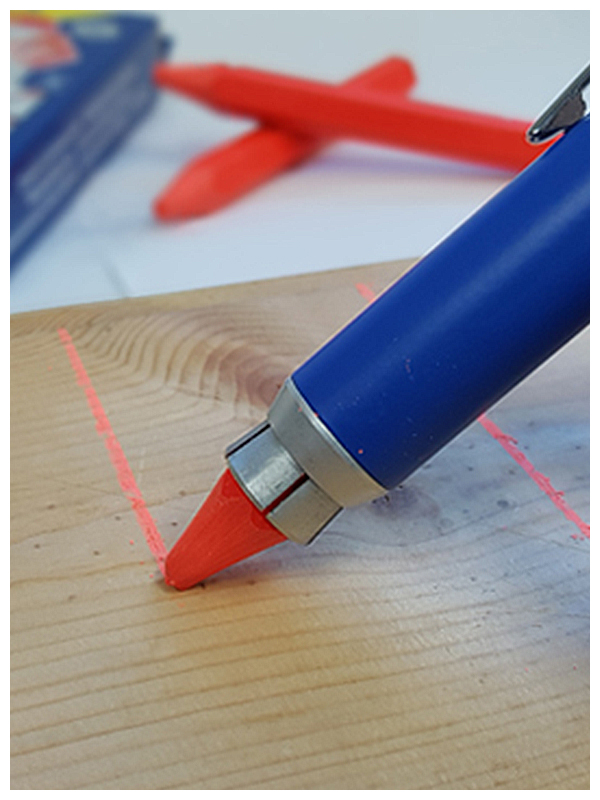

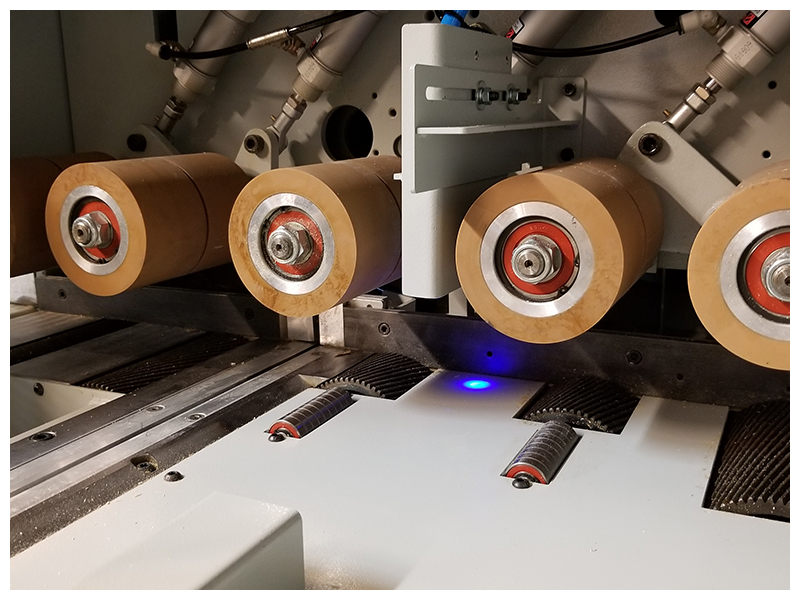

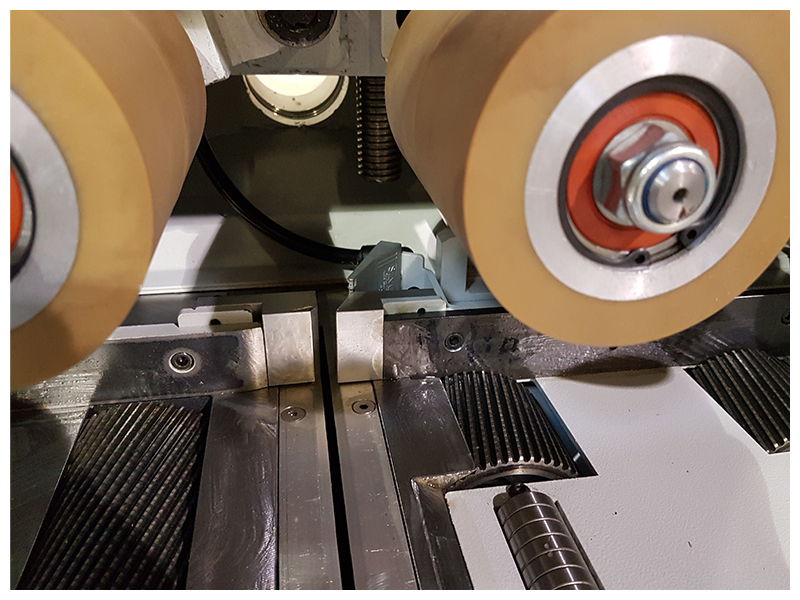

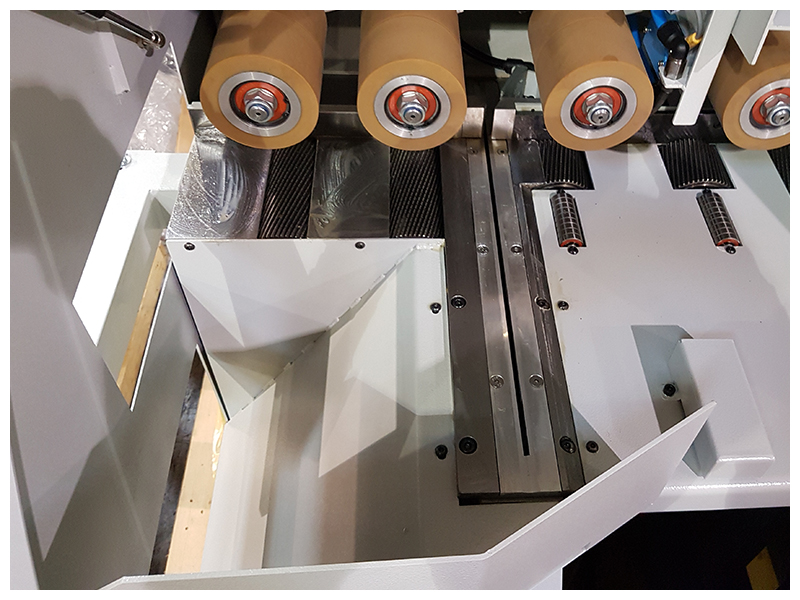

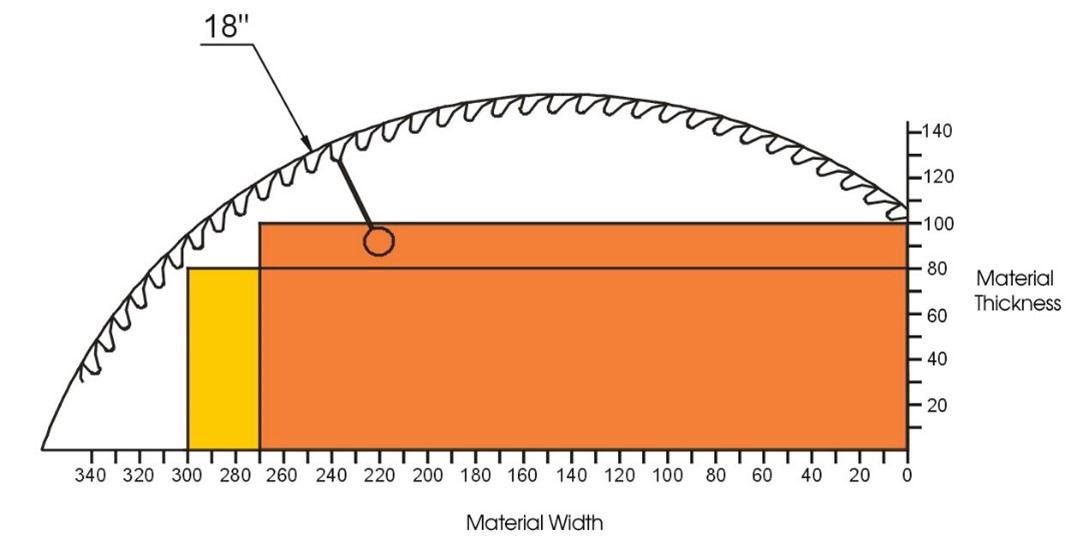

The Cantek CFS100 Automatic Defect Cutoff Chop Saw is the perfect upgrade from your manual cutoff saw with 3 to 5 times higher production output. It is designed to scan for defects in your material which are indicated by a florescent crayon mark. The saw will cut on the crayon mark allowing for fast defect removal. Equipped with several cutting modes like fixed, sequential, defect cutting modes the operator can select the program most suited to their needs. The powerful 10HP motor and 18” blade provide for effortless cutting from 11.8” (w) x 2.75” (t) or 5.9” (w) x 3.9” (t). An optional feature is available for cutting thin material down to 0.078” (2mm) which is ideal for lamellas for engineered flooring.

For flooring companies, the CFS100 can be combined in-line with our EM12 End Matcher for a highly efficient defecting & end matching solution.

Why Cantek CFS100 Automatic Defect Cutoff Chop Saw?

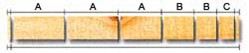

- Ideal for the defect cutting wood mouldings, wood flooring, finger joint blocks, wood paneling and more!

- Machine scans for defects marked with a florescent crayon allowing for high-speed defecting

- Provides 3 to 5 times higher production rate than manual cut-off saws.

- 5% increase in material yield over manual cutting operations

- +/- 1mm (0.0393”) accuracy

- Safe operation with automatic feeding and comprehensive safety guards

- Partial optimization with sequential and fixed part cutting functions or simply cut out defects

- User friendly touch screen control with on board synoptics, cutting counter, and menu based cutting modes

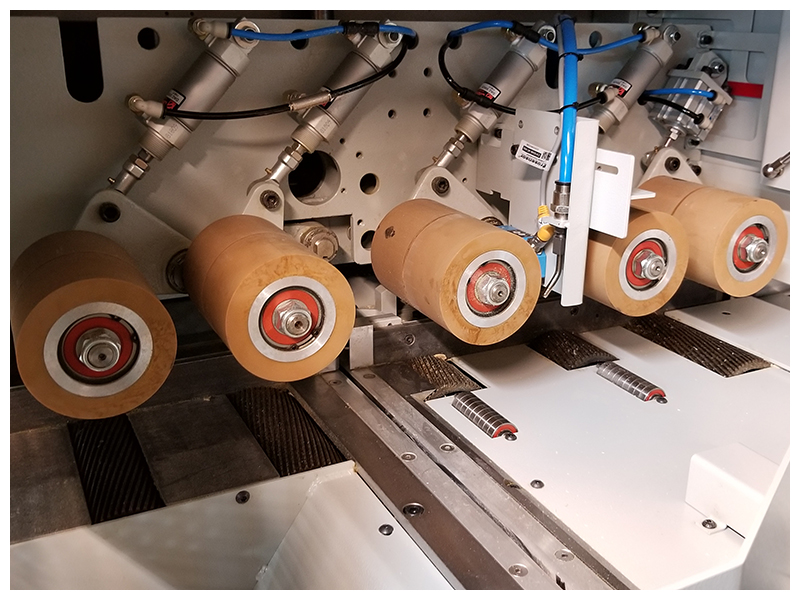

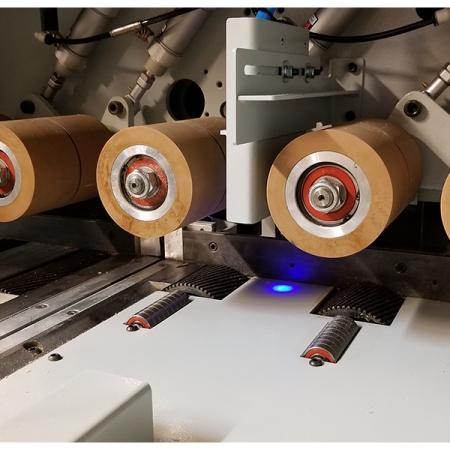

- Servo driven feed motor for fast accurate motion and position control

- Compact design requires less space than manual cutting setups

- 18” diameter blade provides a large cross cutting capacity

- Powerful 10HP motor running at 3200PRM

- Adjustable automatic trim of front and tail of the workpiece

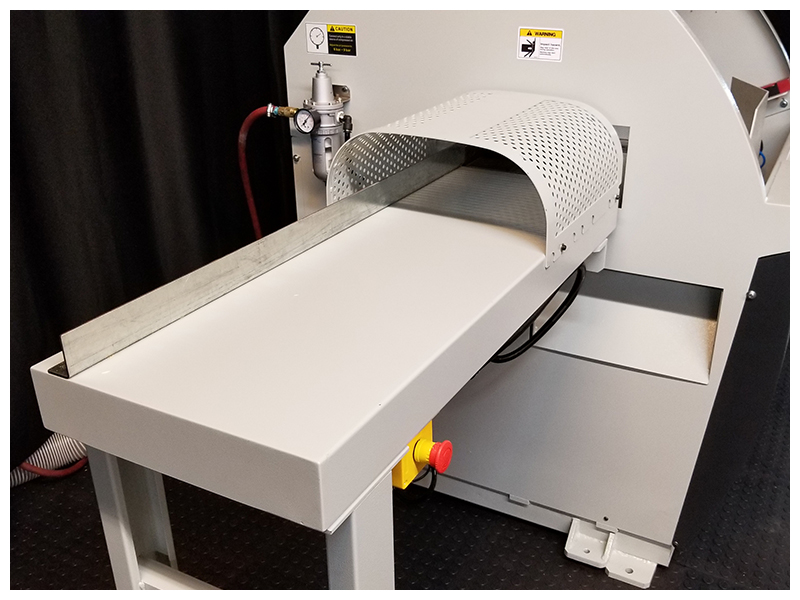

- 48″ (1.2 meter) long infeed table (Longer available on request)

- 40″ (1 meter) long flat outfeed table

- Defect blowing system combined with computerized logic control permits the blowing time and the length of defect to be set as desired

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.