A robust widebelt sander with minimal footprint.

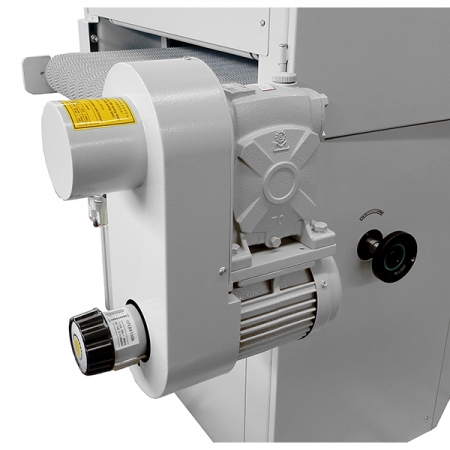

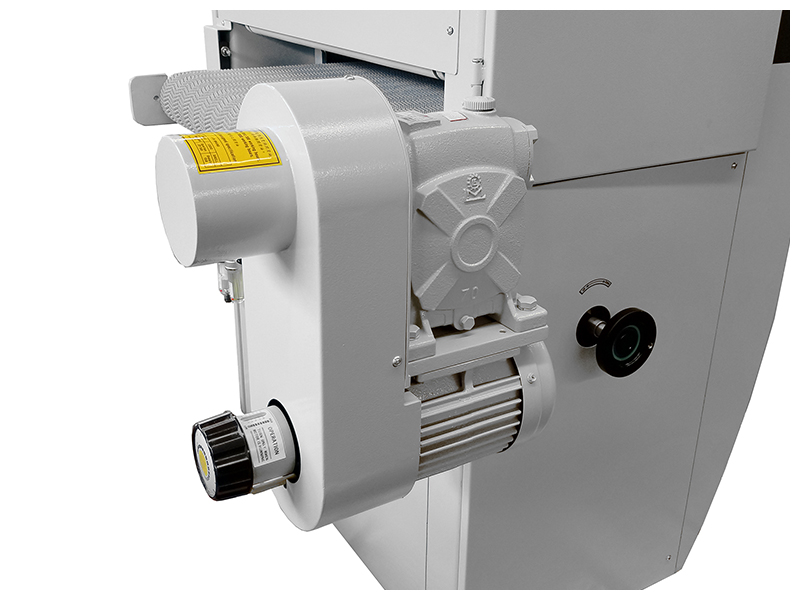

The Cantek C251 24″ Widebelt Sander is compact and versatile with a combination sanding unit for calibration and final sanding. The robust sanding unit and heavy-duty frame ensures optimum sanding results. Motorized thickness adjustment with digital thickness control for fast and accurate table adjustment.

Why Cantek C251 24″ Widebelt Sander?

- Accurate digital thickness control with both Inch & Metric settings allows operator to key in the desired thickness and table will automatically move into position.

- Small footprint

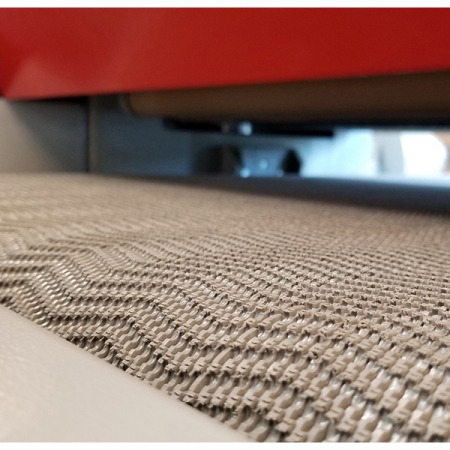

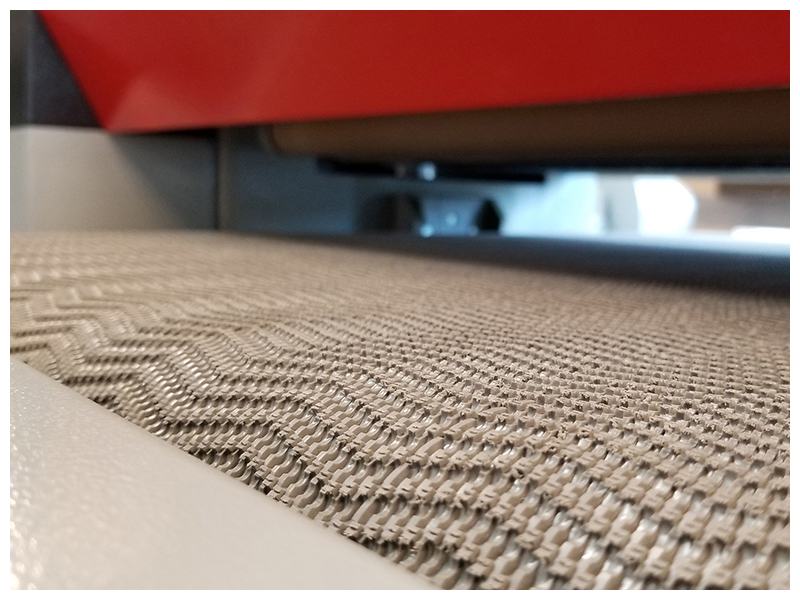

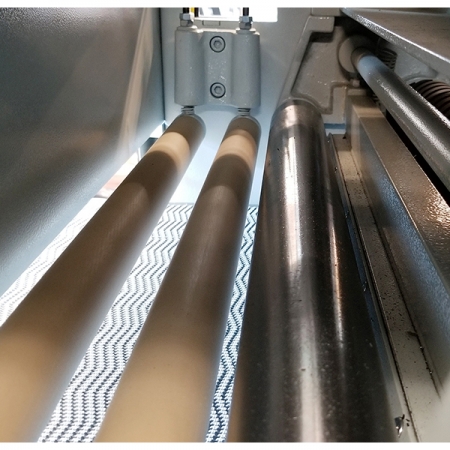

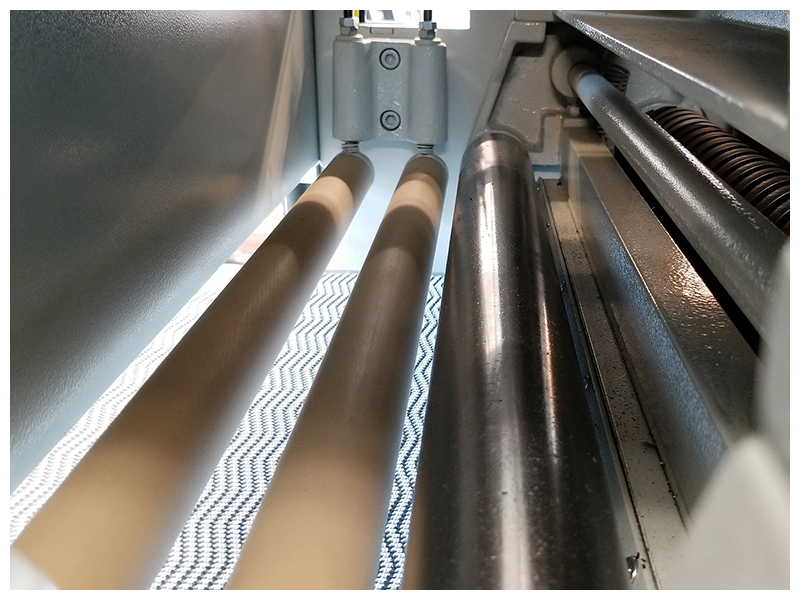

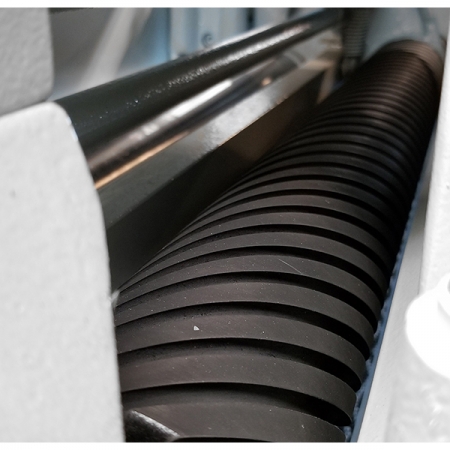

- Combination sanding unit with 3-3/8” rubber contact drum and 2” wide adjustable sanding platen for a wide range of sanding applications.

KEY ADVANTAGES

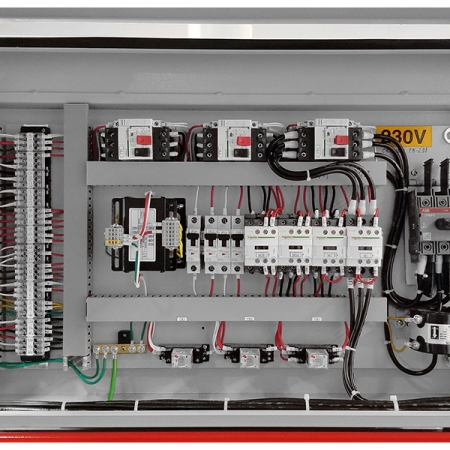

- Electronic belt tracking for optimum belt life and sanding results

- Ammeter for load monitoring to ensure the proper amount of material is being removed according to the selected grit.

- Disc brake on main motor allows for faster belt changes

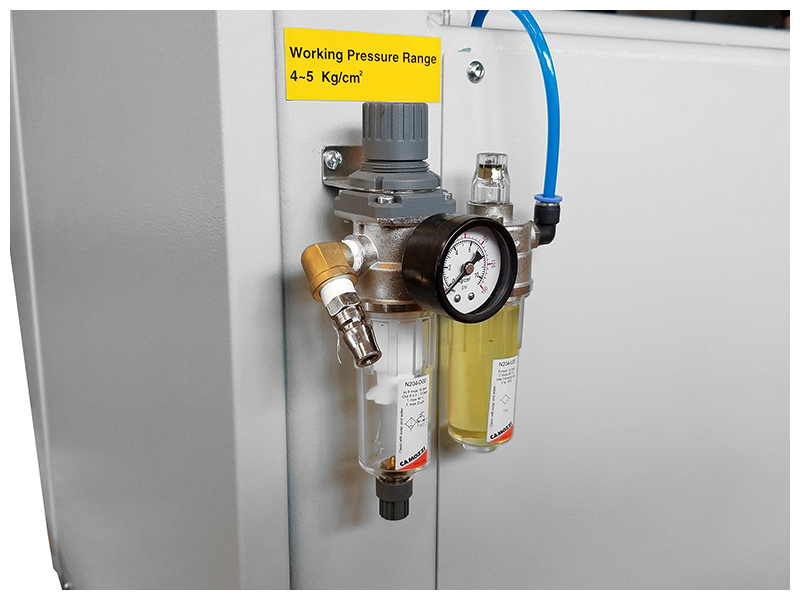

- Pneumatic belt tensioning with quick release outboard support to facilitate fast belt changes.

- Double infeed and outfeed pressure rolls for superior part hold down

- Material over-height limit switch

- Hour meter records the actual running time of the machine which can be used to provide timely maintenance for the machine

- Interlocks located on all access doors.

SPECIFICATIONS

SERVICE

Sanding to Perfection: Achieving a Fine Finish.

Machinery Solutions, Service and SupportThe journey to a fine finish in sanding is the culmination of transforming raw wood into a refined and desirable surface, ready for the application of the final finishing products.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Why Consider a Planer Sander?

Machinery Solutions, Service and SupportTraditionally shops have a surface planer and/or wide belt sander to calibrate and prepare their products for finishing. Understanding the differences between a planer and a sander and how efficiently using a planer sander can benefit your production can be vitally important to your business saving time and money.