Save time and speed up production in your ripping operations.

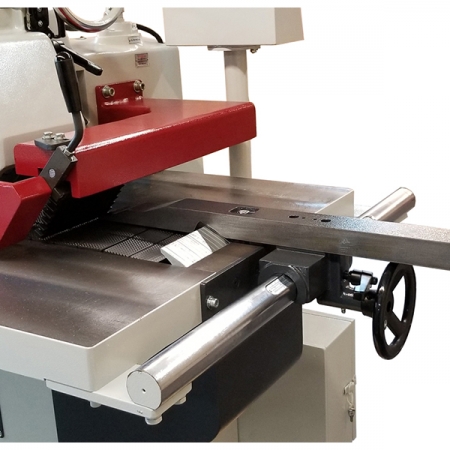

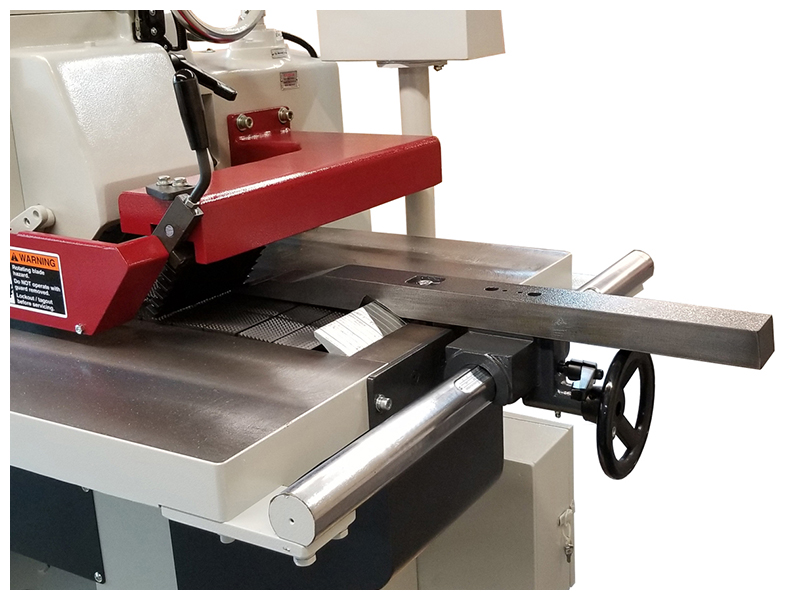

The Cantek 303S single blade ripsaw is a straight line ripsaw that is the ideal ripping upgrade for those looking to prepare material for a moulder or for producing face frame material. The 303S automatically feeds the material for consistent rip results. The cast iron feed chain runs on double V guide rails and holds the material firmly for precision straight cutting. A powerful 10 HP motor with maximum 12” blade provides a cutting depth up to 3.35”. A micro adjustable infeed fence allows for quick setups to ensure precise rip widths with fast adjustments.

Why Cantek 303S Single Blade Ripsaw?

- Rigid machine body consists of a thick welded steel frame with an integral table which is fitted with a sturdy cast column.

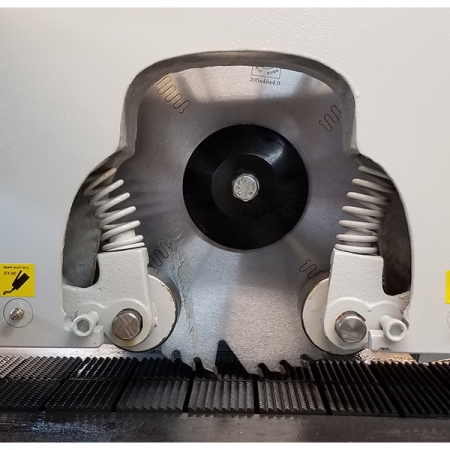

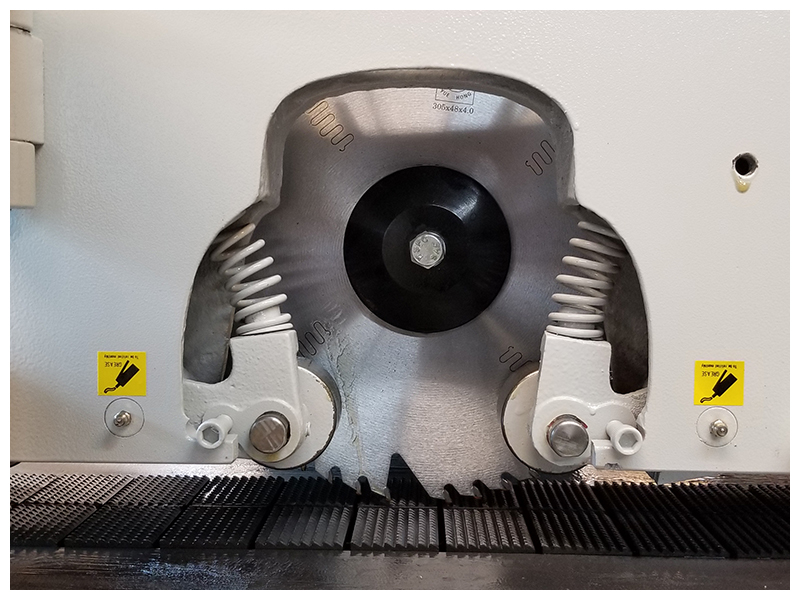

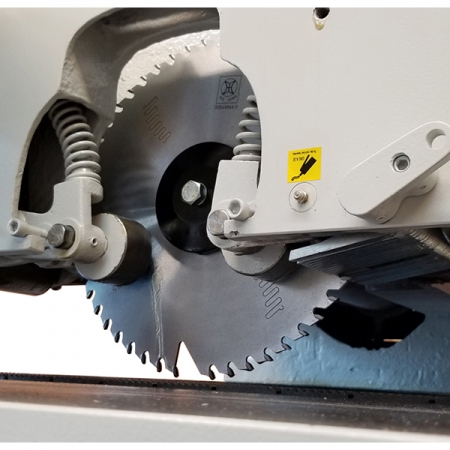

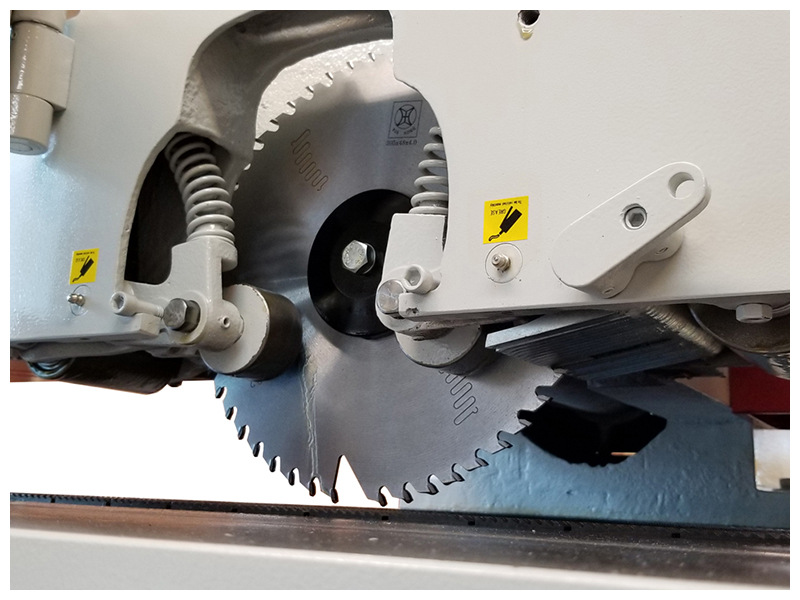

- Precision built saw arbor constructed to ensure precision cutting without vibration.

- Cast iron upper assembly & cast iron table with superior vibration damping for optimum results

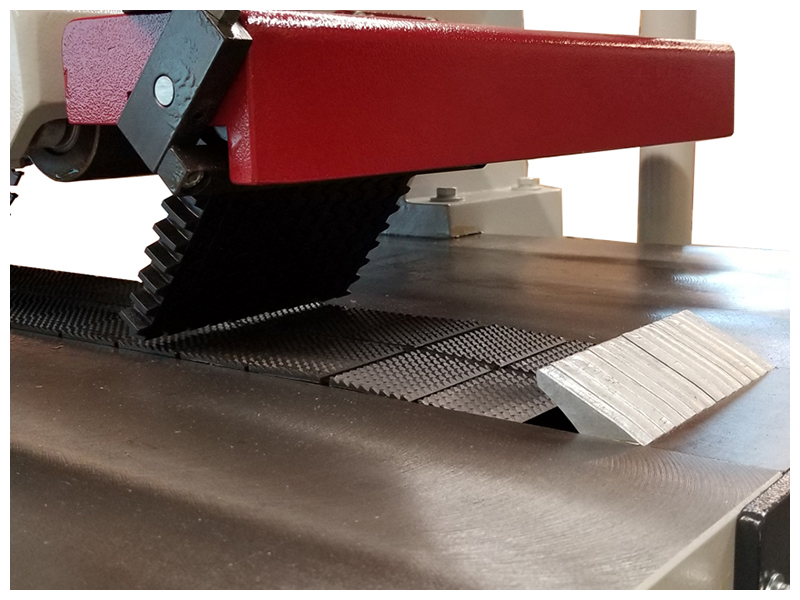

- Micro adjustable fence by rack and pinion for fast setups with precise results

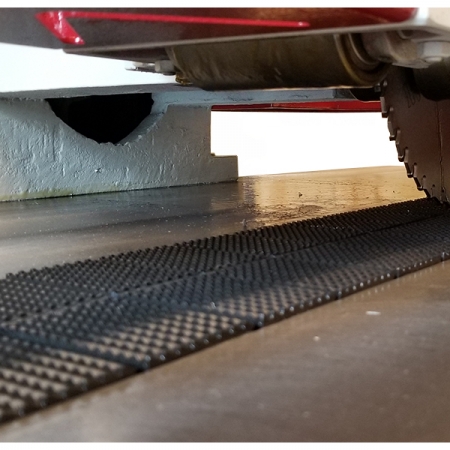

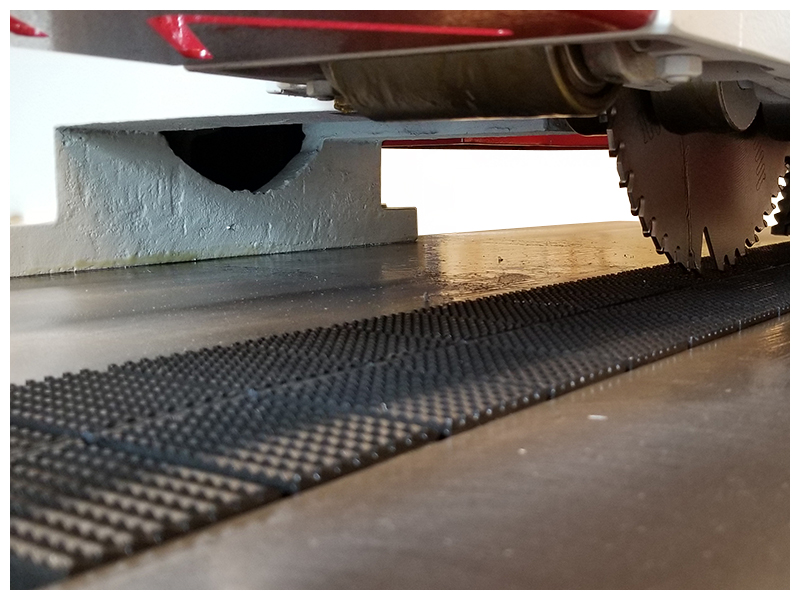

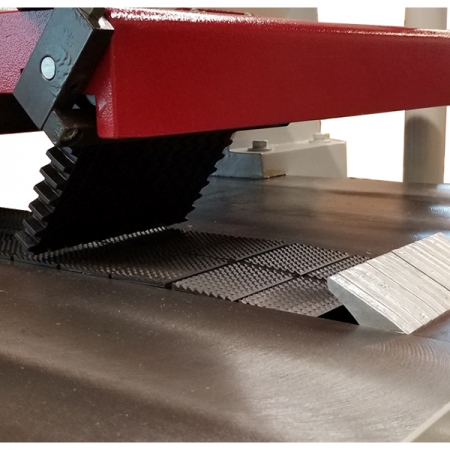

- Cast iron chain and track assembly is precision machined and hardened for maximum wear resistance with superior cut quality

- Two rows of anti-kickback fingers for safe operation

- Swing down rear table prevents short workpieces and thin edgings from jamming in the machine

- Electronic chain lubricator provides consistent lubrication to the chain track for optimum wear resistance

- Powerful 10HP motor

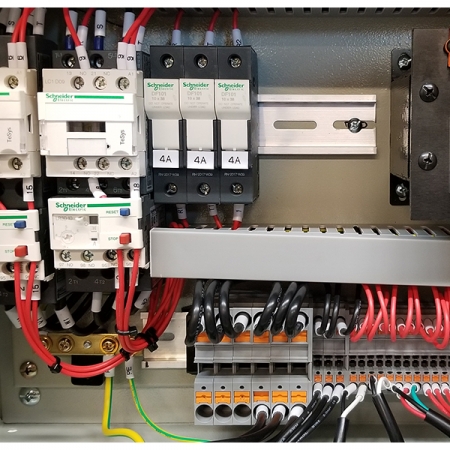

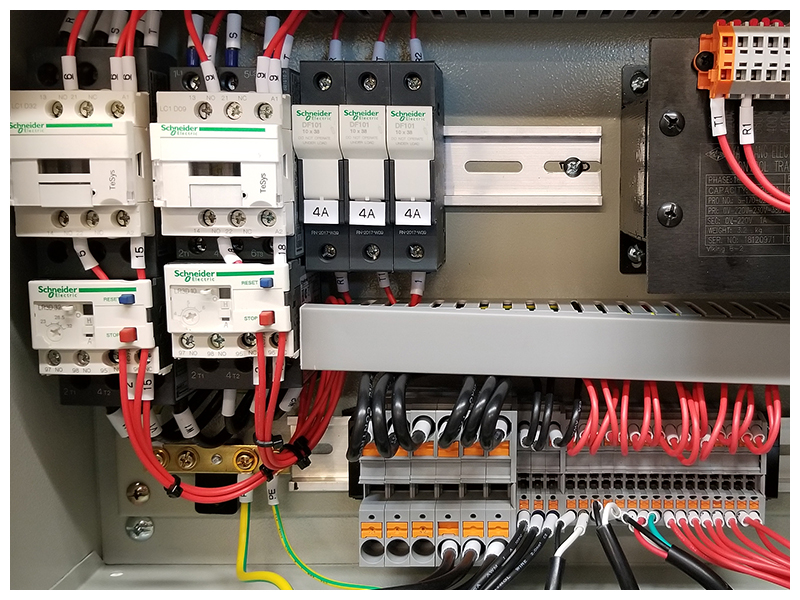

- Three feed speeds can be externally adjusted for operator convenience

- Mechanical digital readout for setting the workpiece thickness

- 12” blade is included

- Optional laser light for projecting the cutting line

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.