Reduce costly setup time on your edgebander.

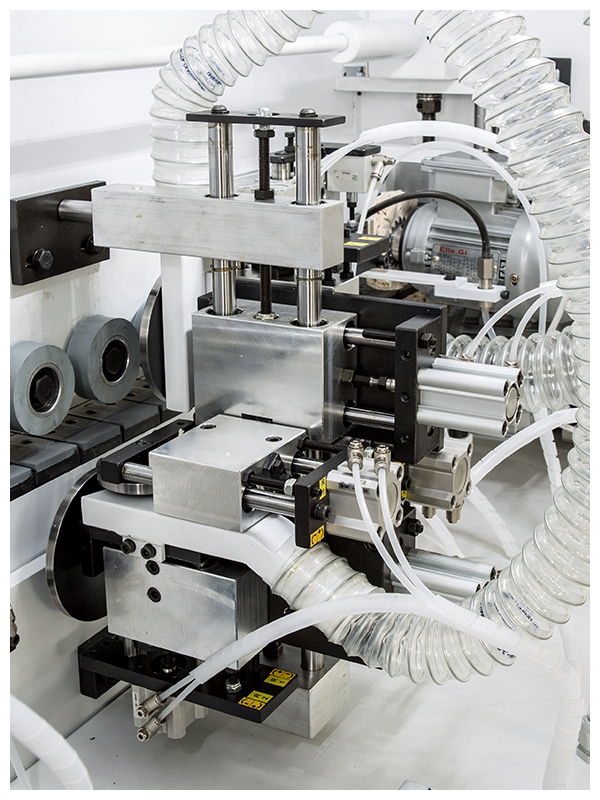

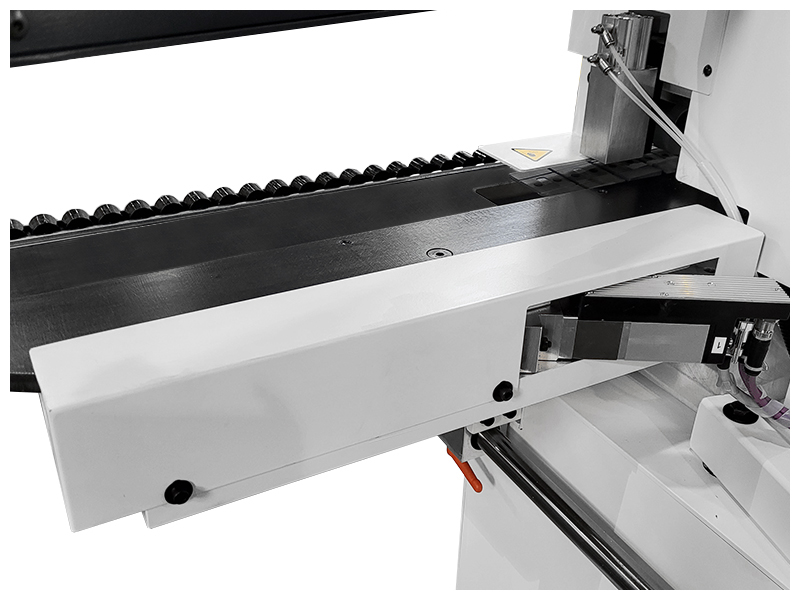

The Bi-Matic Prima 7.3 Plus ONE Programmable Edgebander is an automatic edgebander that allows you to store machine settings for instant recall. With DC servo controls for various functions on the machine setup time is reduced to seconds. Servo controls also mean accurate and repeatable results time after time.

Why Bi-Matic Prima Plus 7.3 ONE Programmable Edgebander?

- Store settings for working units allowing for immediate recall and automatic setting according to the desired edge to be applied

- Greatly reduce machine setup time and spend more time edgebanding

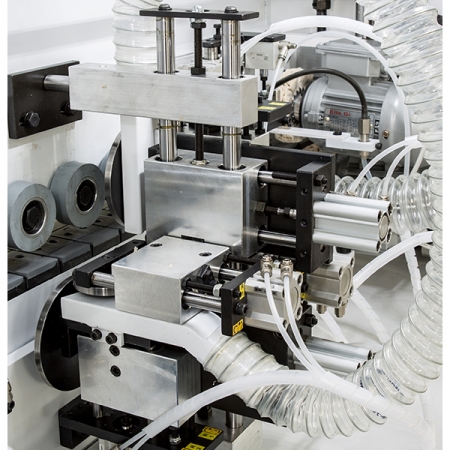

- Quick change glue pot allows for the rapid changing between glue types or colors

- Screw glue roller system is capable of applying EVA or Polypropylene glue which has a lower viscosity for virtually invisible joints

- The full package for cabinet parts, cabinet doors, and more.

KEY FEATURES

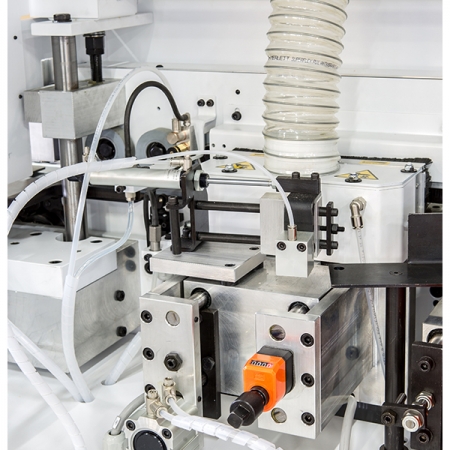

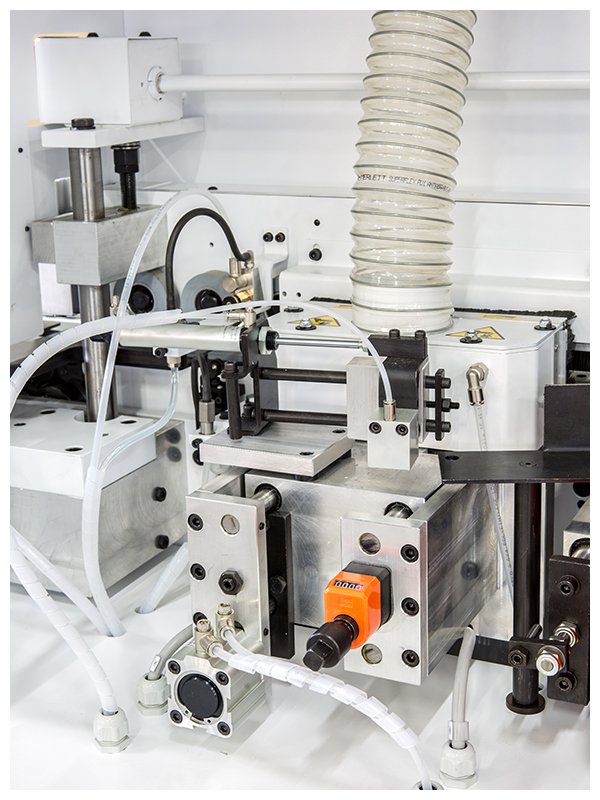

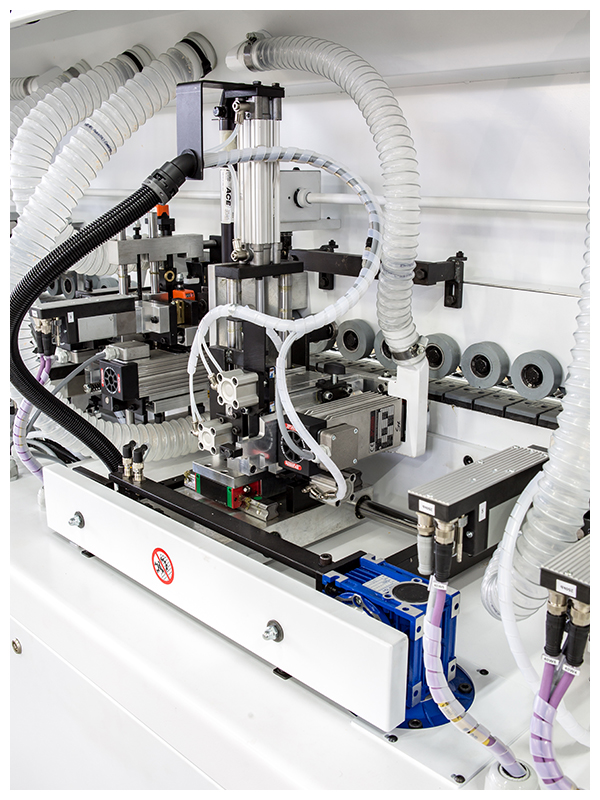

- 15” touch screen control capable of storing machine settings

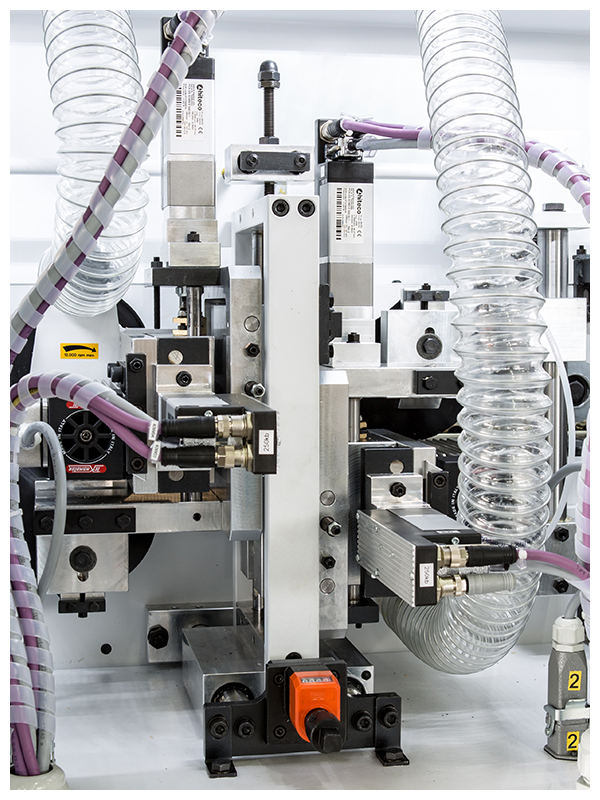

- Automatic machine adjustments to certain units by servo and pneumatic controls

- Auto setting infeed fence according to the edge thickness being applied

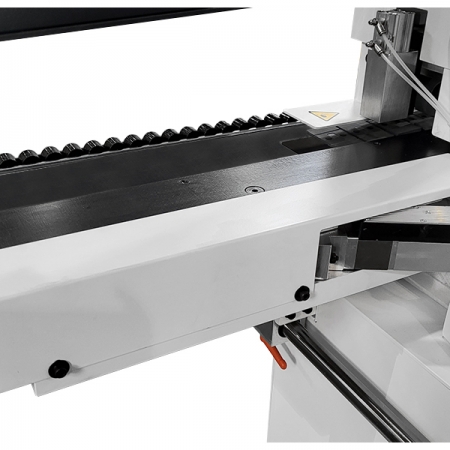

- Narrow part insertion device to ensure panels are fed squarely into the machine

- Dual telescopic panel support to properly support wider pieces during edgebanding operations

- 5 litre Teflon coated glue pot with quick heating time of 5-6 minutes

- Quick change system allows for fast exchange of the glue pot when using different color glues or different glues (when extra glue pot(s) are ordered)

- Screw Glue Roller system allows for proper glue delivery of higher viscosity glues like Polypropylene resulting in virtually invisible glue joints

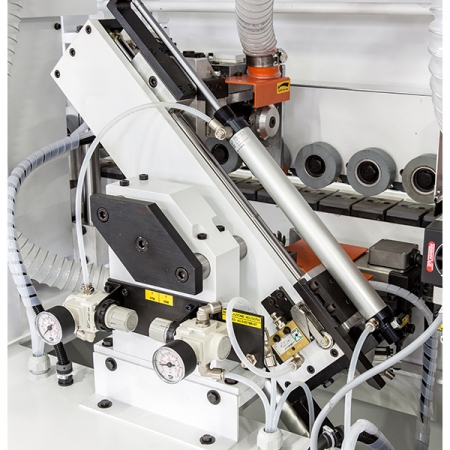

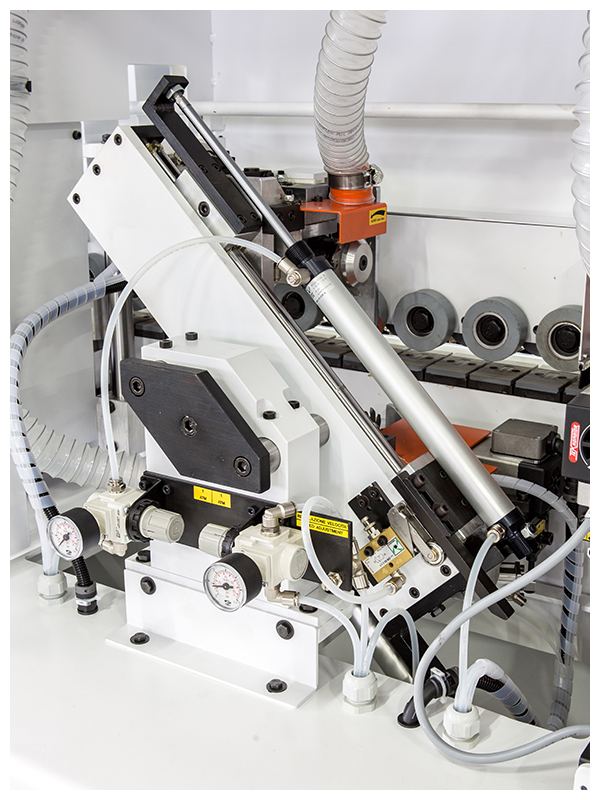

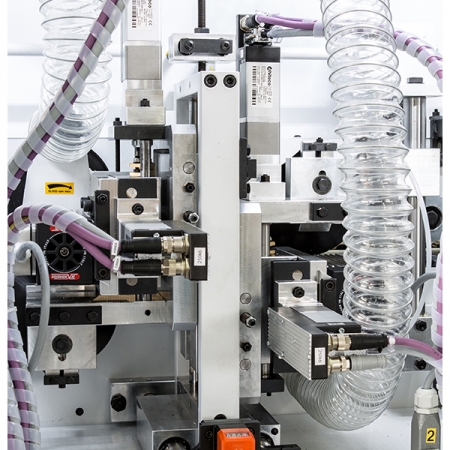

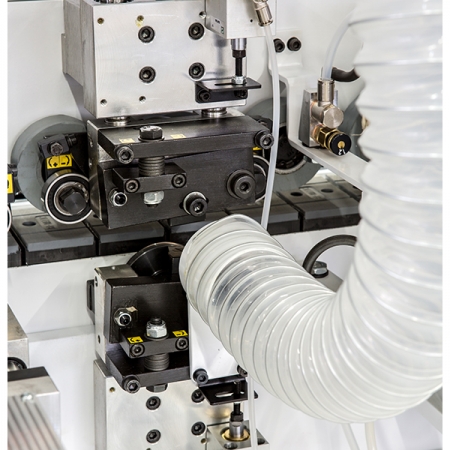

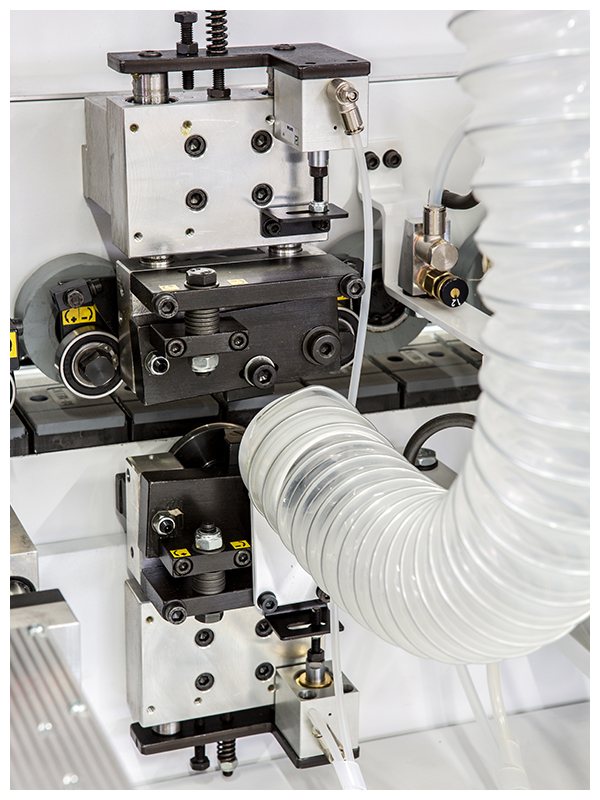

- Counter rotating diamond pre-milling cutters to ensure an optimum edge for higher quality joints

- Dual motor end trim with pneumatic inclination from the control system

- High frequency top & bottom edge trimming units with servo setting

- Corner rounding unit for finishing the ends of the panel with pneumatic 2-position dual radius selection from the control panel.

- Radius scraping unit with multi radius knives

- Glue scraping system to remove any excess glue to eliminate any re-working of the panel

- Buffing unit to polish edges after machining

- Nesting rollers for proper machining of doors with hinge holes already process

- Riepe LPZ/II anti-adhesive spray system prior to pre-milling unit

- Riepe LP163/93 polishing system before buffing unit to promote a vibrant edge

SPECIFICATIONS

One Anderson.

Corporate, Machinery SolutionsAkhurst has made the move to distribute all of Anderson’s machines under one brand, Anderson. Anderson is the world leading CNC router manufacturer, with over 20 thousand machines sold worldwide and 5 thousand only in the US market.

When does pre-milling make sense?

Machinery Solutions, Service and SupportOver the past few years, pre-milling has grown in popularity. Pre-milling is the process of machining the edge of the panel prior to applying glue. It ensures optimal edge quality before the application of edge banding, resulting in reduced glue joints and a highly aesthetic edge.

Visit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Corporate, Machinery Solutions, Trade ShowsThe WTD is back with extended dates, now giving visitors five days to visit our members’ extensive showrooms and see the latest new technology, including some North American premieres. No other show or single event offers you such a wide display of woodworking equipment, combined with impressive live demonstrations at each location.