Machine Information

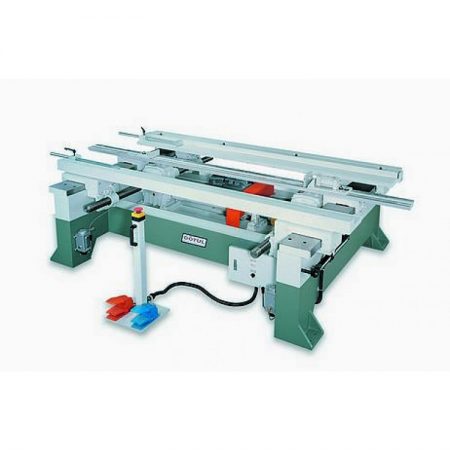

The single sided cold press machine is designed to press 40 pieces of 15/16″ thick stock to build 1 7/8″ thick door stiles, or 50 pieces 3/4″ stock for 1 1/2″ thick door stile blanks, 3″ to 11 3/4″ wide and 48″ to 97″ long.

This press can also be used to apply veneers to a substrate, or any type of core material desired. The opening is 37 1/2″ in height and must be filled within 1 1/2″ from the top of the stack with material in order for the platen to engage the top of the stack. Which ensures the correct amount of pressure is applied to the load.

This machine is constructed of heavy duty “I” beam frame and tube stock, welded securely for continuous duty. Thirty thousand (30,000) pounds of air pressure is applied to the platen by two 3 1/2″ diameter air bladders at a regulator setting of 100 PSI. The platen applies pressure to the outsides of the stile blanks ensuring tight glue lines. UHMW covered adjustable locating arms are furnished to ensure the stack of material is placed in the center of the platen and the stack is straight up and down.