High Speed, High Precision CNC Router with Magnetic Linear Drive Technology.

The Anderson EXXCEL High Speed CNC Router sets a new level of very High Precision CNC accuracy and machining performance. The combination of a highly rigid base, steel weldments and castings and high accuracy Linear Motor Servo System make the EXXCEL an ideal choice for machining wood, MDF, plywood, plastic, aluminum, and composite materials.

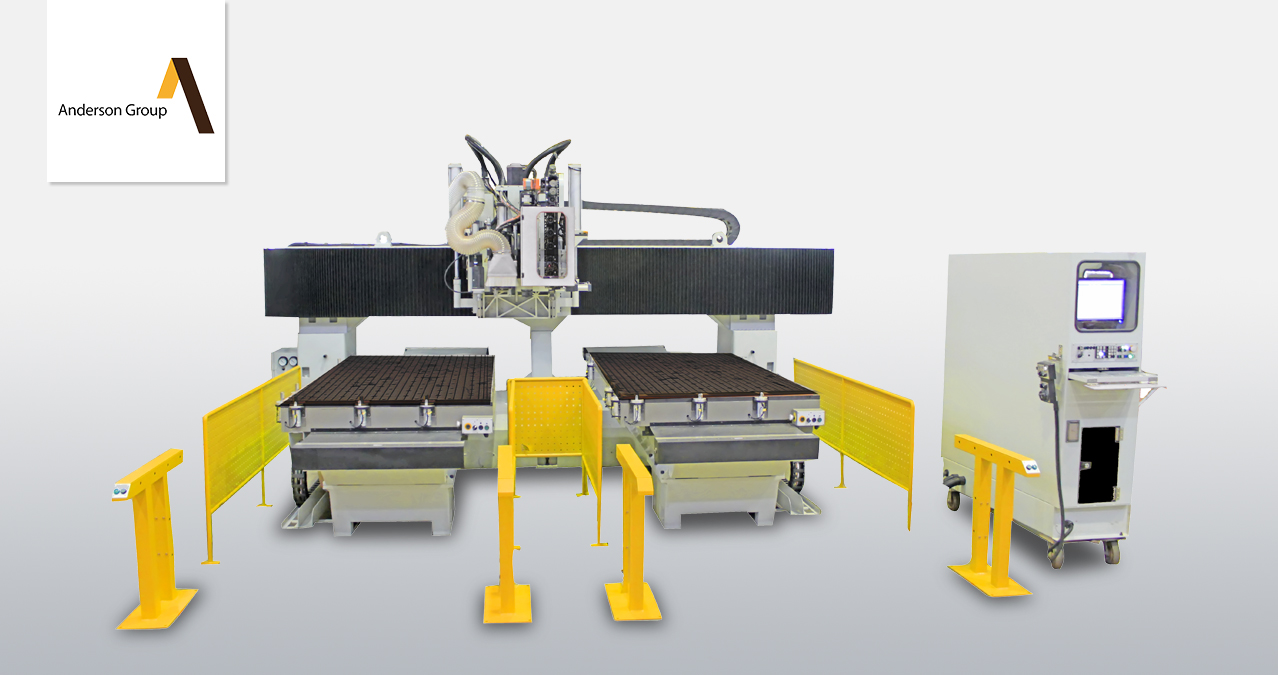

The Anderson fixed bridge, moving table design and all magnetic drive motors make the EXXCEL one of world’s fastest and accurate CNC routers. The webbed steel substructure and Linear motor drives provide the EXXCEL with a very rapid acceleration profile as well as superior accuracy and extremely low vibration. The EXXCEL CNC machining centers set a new standard in very high precision, high speed CNC machining. The EXXCEL CNC machining center is designed to handle high speed CNC machining, trimming, slotting, and drilling on all types of hardwoods and more. CNC Controls include Ethernet options to provide remote technical support; optional C-axis is available.

Work piece holding flexibility is provided by optional clamping, grid, or manifold vacuum systems. The EXXCEL CNC Machining Center utilizes an industry standard G-code for control functions that allows easy interfacing with all major CAD/CAM software and industry standard solid modeling software packages. Additional options include work piece dimension probing, both single and dual zone capabilities and custom configurations upon request.

Why Anderson EXXCEL High Speed CNC Router?

- High speed linear drive system making it one of the worlds fastest CNC routers

- Heavy duty fixed bridge & moving table design for the highest precision routing results

- Wide range of configurations to choose from to suit your needs from single or multi tables, single or multi router spindles, drill heads and more.

- RanRob tool changer for the fastest tool changes available resulting in reduced cycle times

- Box way design holds the tightest tolerances

Basic Configuration |

EXXCEL |

EXXCEL DUO |

No. of tables |

1 |

2 |

No. of vacuum zones per table |

1 |

1 |

Table size X |

3700 mm (146″) |

2x 1840 mm (73″) |

Table size Y |

1600 mm (63″) |

1600 mm (63″) |

Stroke of X-axis |

4450 mm (175″) |

4450 mm (175″) |

Stroke of Y-axis |

1800 mm (71″) |

1800 mm (71″) |

Stroke of Z-axis |

300 mm (12″) |

300 mm (12″) |

Rapid travel Speed in X |

100 M/min |

100 M/min |

Rapid travel Speed in Y |

100 M/min |

100 M/min |

Rapid travel Speed in Z |

30 M/min |

30 M/min |

Power |

15 HP |

15 HP |

Max. Speed (rpm) |

1.000-22.000 rpm |

1.000-22.000 rpm |

Clamping system |

HSK-63F |

HSK-63F |

Tool Changer |

max 32 |

max 32 |

Boring block |

Anderson Type |

Anderson Type |

Vacuum pump |

25 HP |

25 HP |

Controller |

ANDI-FANUC |

ANDI-FANUC |

Dimensions: Floor Area |

6500 x 4200 mm(256 x 165″) |

6500 x 4200 mm(256 x 165″) |

Height |

3300 mm (130″) |

3300 mm (130″) |

Weight |

11000 kg |

11000 Kg |

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.