Save time walking around your saw with a CNC rip fence.

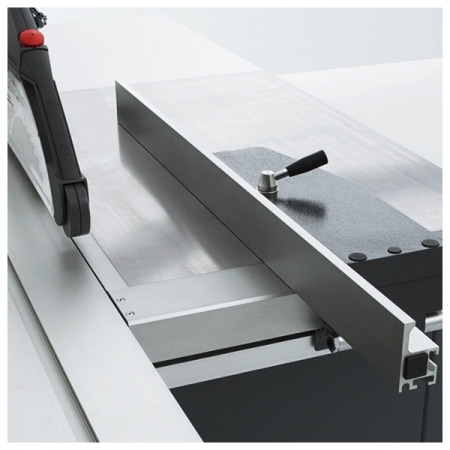

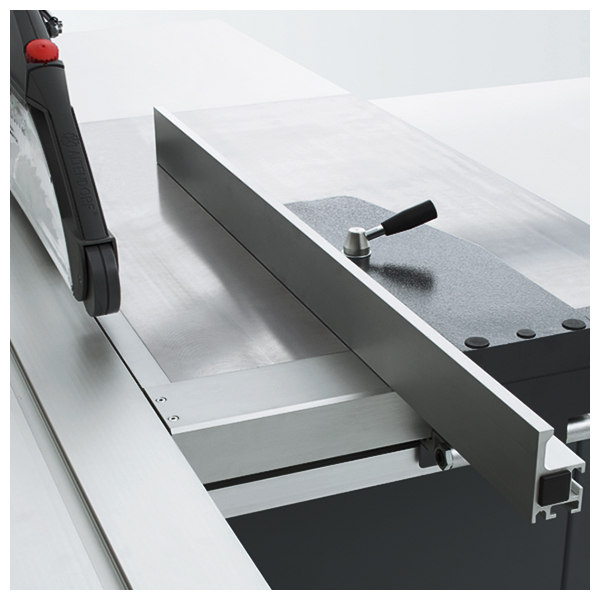

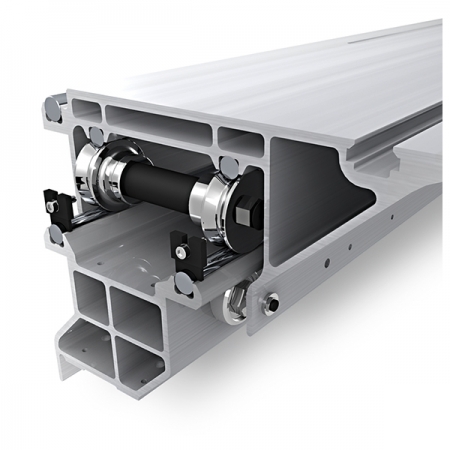

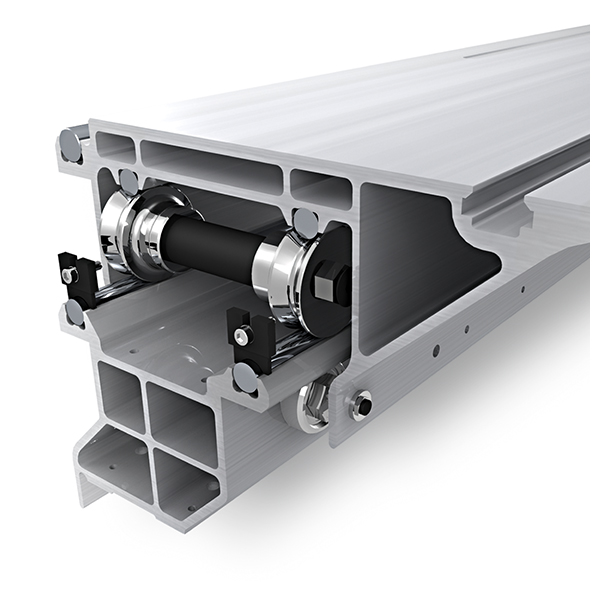

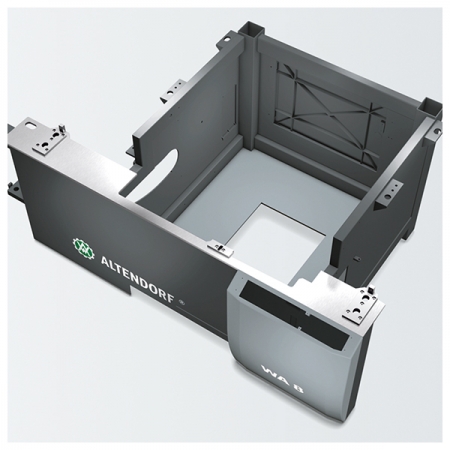

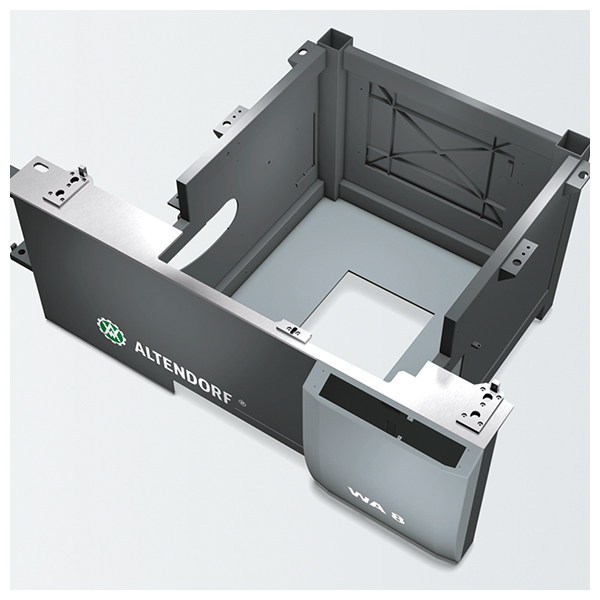

The Altendorf WA8X Sliding Table Saw is the perfect solution for workshops that require the precision offered by Altendorf with a lower entry price point. The WA8X features a precision CNC rip fence for fast and accurate adjustment every time. The user-friendly eye level control panel allows the operator to key in the rip fence setting and adjust the height and angle of the blade in addition to starting and stopping the main and scoring blades. The sliding table is typically Altendorf, smooth running, accurate and incredibly reliable due to the tried and trusted double roller carriage. The saw unit is powerful and well balanced as you would expect from this prestigious manufacturer, who has been making panel saws for over 111 years.

Why Altendorf WA8X Sliding Table Saw?

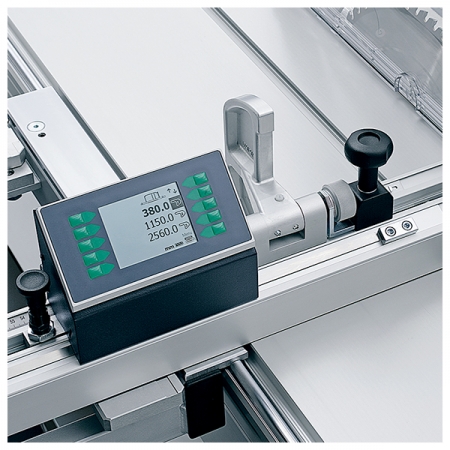

- CNC rip fence with repeatable accuracy to +/- 0.1mm

- Precision sliding table which Altendorf has become the benchmark of the industry

- Eye-level control panel for controlling the blades on/off, rip fence position, and blade tilt angle

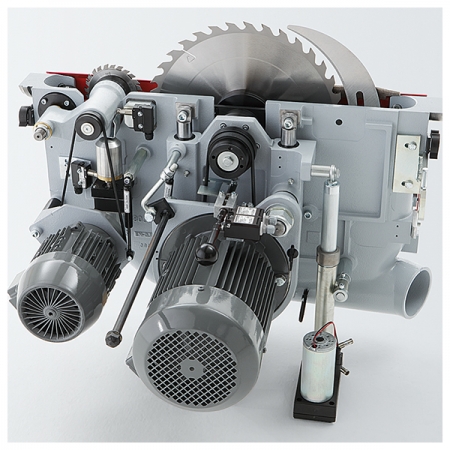

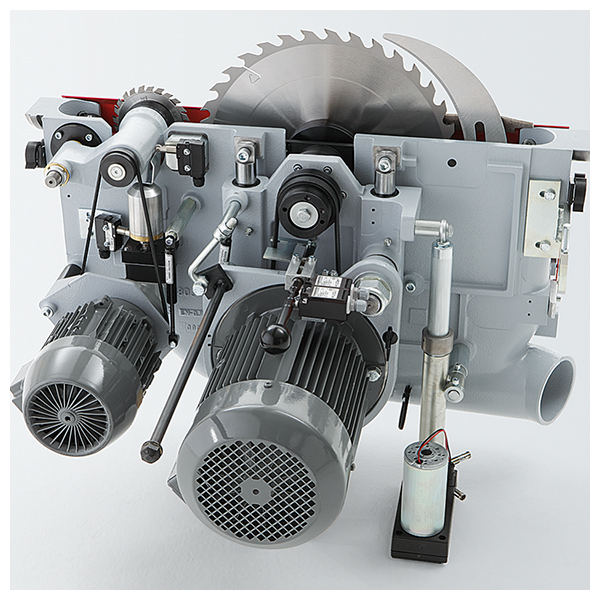

- Powerful 7.5 HP main motor with separate 1 HP scoring motor for a wide range of cutting applications

- Programmable rip fence with maximum cutting width of 1300mm (51”) by means of a precision ground ball screw & linear guide

- Extrusion can be flipped for narrow bevel cutting or to trim panels with overhanging veneers / laminate. Change in dimensions is automatically compensated for in the controller

- Motorized blade rise/fall

- Motorized blade tilting with electronic angle display on control panel

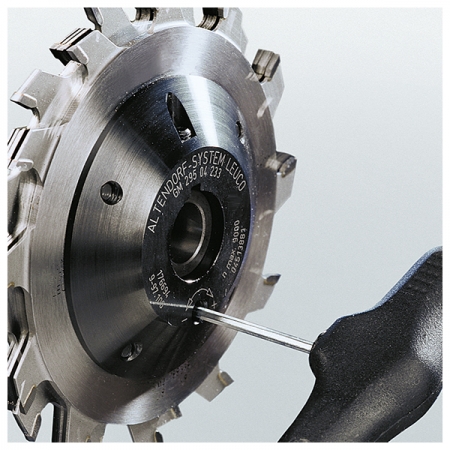

- Scoring blade with motorized rise and fall and manual lateral adjustment

- 7.5 HP main motor with separate 1HP scoring motor

- (3) saw blade speeds for optimum cutting results in various materials

- Precision anodized aluminum sliding table with large dumbbell style steel rollers and hard chromed guide rails.

- Aluminum extruded crosscut fence with (2) flip stops.

- Solid cast iron main table which is ground and polished

- Heavy-duty outrigger for strong support of workpiece during cutting operations

- Optional single sided miter fence for angled cuts with single stop to 2500mm (included)

- Overhead CE blade guard with built in dust port and straight and bevel blade guards

- Complete with eccentric clamp for securing difficult to hold materials

- Optional: DIGIT L crosscut fence with digital readout and DUPLEX double sided mitre fences available

High-end cabinetry, movie stars, Marvel has it all.

Case Study, Corporate, Machinery Solutions, Service and SupportMarvel Cabinetry, from De Winton, AB, is the exclusive cabinetry supplier for the first and second seasons of Property Brothers’ Celebrity IOU on HGTV, and has designed and built made-in-Canada cabinetry for stars across North America. Among them were Michael Bublé, Brad Pitt, Snoop Dogg, Gwyneth Paltrow, Melissa McCarthy, Viola Davis, Jeremy Renner, Kevin Hart, Howie Mandel, and LeAnn Rimes, and Marvel invites you to be next.

Achieving optimum performance from your edgebander.

Service and SupportEdgebanders tend to be one of the more complex machines to operate in a woodworking shop, and their performance has a vital impact on the quality of your finished product. Proper machine setup, maintenance, and cleaning play a major role in achieving the best edgebanding results. Below are some basic tips that can greatly reduce the downtime you experience on your edgebander and keep it producing quality components.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.