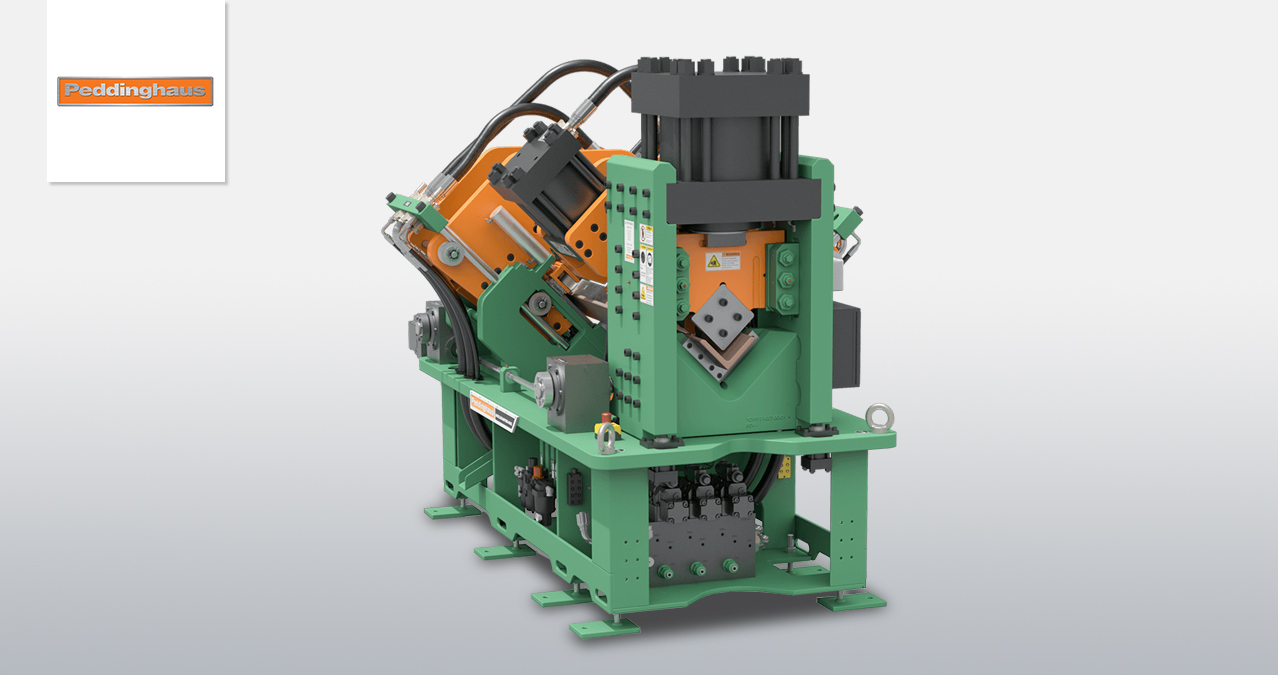

The New Benchmark for Angle and Flat Bar Processing.

Serving as the industry’s benchmark for productivity, the Peddinghaus Anglemaster-663 Angle Line caters to today’s fabricators’ need to automate punching, shearing and marking for angle and flat bar. The Anglemaster-663 can accommodate shaped holes such as squares, rectangles, obrounds, and slots, including a feature that allows nibbing of material. The unit offers a new punch tool design that helps simplify tool changes, as well as a misting feature that extends punch tool and shear life during operation. A new patent-pending roller feed flexes with the material to help ensure a constant roll and accurate measurement given deviations in material, with no stop in production.

Why Peddinghaus Anglemaster-663 Angle Line?

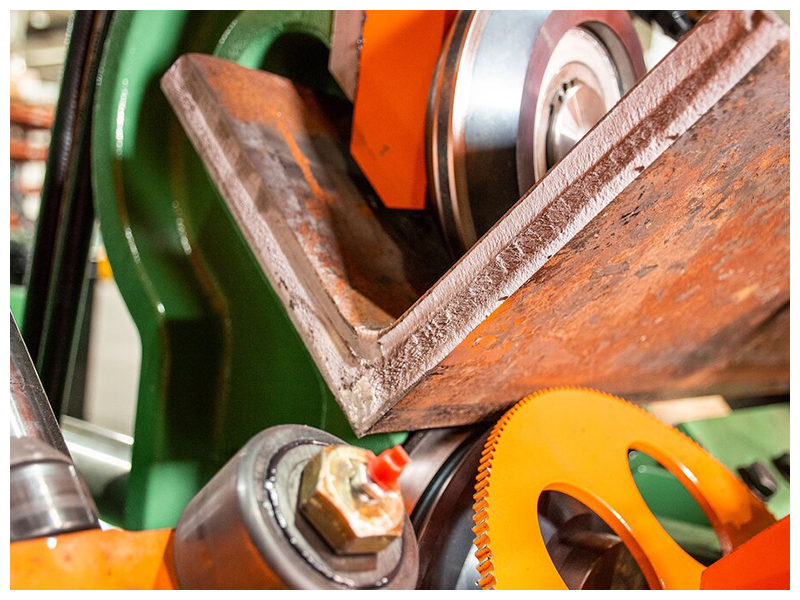

- Innovated patented Roller Feed is designed to flex with the material in order to ensure a constant roll and an accurate measurement given deviations in material, maximizing contact with long parts

- Two encoders on the machine to allow steel to pass through piece after piece with no stop in production

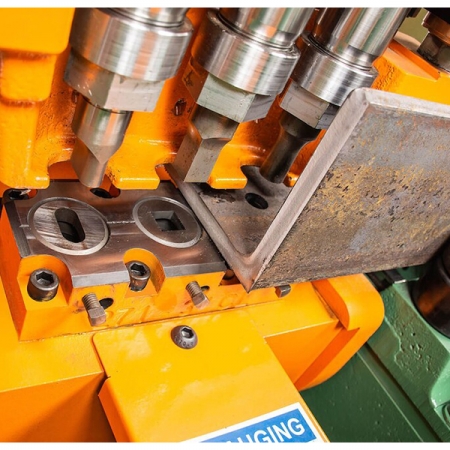

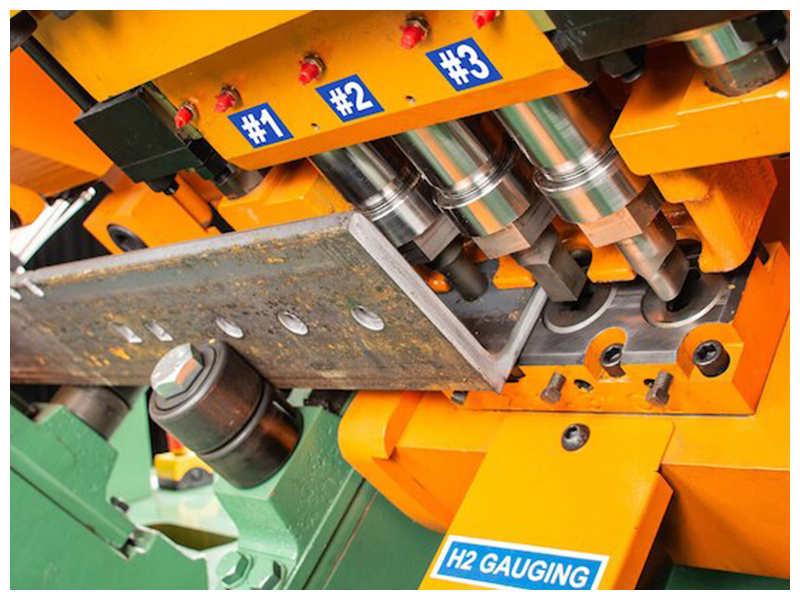

- Three punch stations per hydraulic press allow the machine to apply up to three different hole shapes/sizes per leg

- The Anglemaster-663 uses a single cut 290 tonne shear press for the cutting to length angle and flat stock, eliminating the slug created by double cut shear mechanisms

- The material handling system alleviates cost and labour associated with moving sections with the use of rapid, automated sequence process

6 Punches for Tooling Capacity

Three punch stations per hydraulic press allow the machine to apply up to three different hole shapes/sizes per leg. A new and improved punch tool design allows for quicker and easier tool changes. The Anglemaster-663 can accommodate shaped holes such as squares, rectangles, obrounds and slots, including a feature that allows nibbling of material for cutting large notches out of angle or flat bar.

Powerful Shearing

The Anglemaster-663 uses a single cut 320 ton shear press for the cutting to length angle and flat stock. A single cut shear mechanism eliminates the slug created by double cut shear mechanisms.

SignoScript Carbide Scribing

The SignoScript layout marking attachment eliminates human error in manual layout methods. Complete information is maintained throughout blasting, galvanizing and painting processes

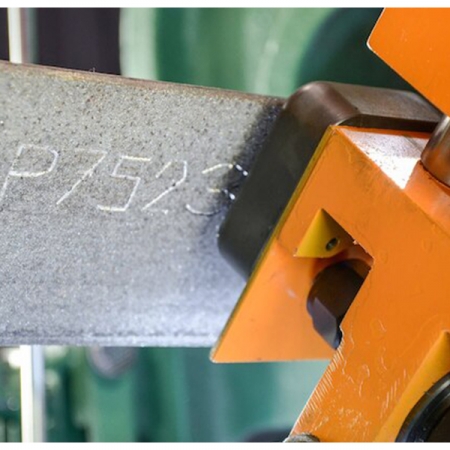

SignoMat Part Stamping

The SignoMat part stamping unit stamps at an unmatched 1 character per second with a depth of 1/32″ (.8 mm) and a total height of 1/2″ (12 mm). The unit holds up to 36 characters for complete part marking ability.

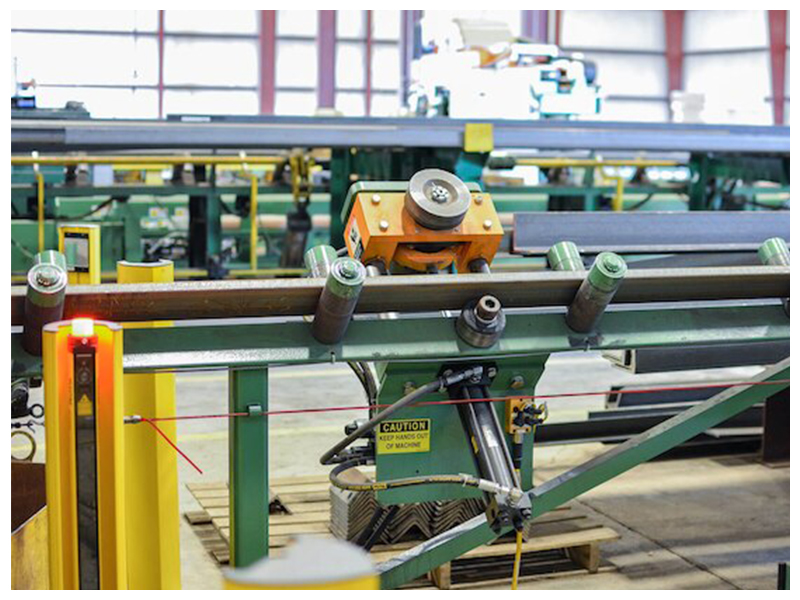

Nonstop Throughput with Roller Feed Technology

Equipped with the Peddinghaus Roller Feed measurement system, the Anglemaster-663 maximizes contact with the material at all times. This Roller Feed technology ensures a constant roll and an accurate measurement given deviations in material.

Lubrication System Prolongs Tool Life

The lubrication system on the Anglemaster-663 extends to the shear, now allowing for longer shear life. Overall angle production and tool life is enhanced with the Minimum Quantity Lubrication (MQL) system.

Infeed and Outfeed Material Handling

The infeed and outfeed material handling system, designed for continuous production, keeps the operator safe at all times. As drag chain conveyors move material to the infeed conveyors, power material advance initiates steel into the machine. Once sheared, drive rollers advance the finished parts to the unloading zone.

Raptor 3D CAD/CAM Software

Developed by Peddinghaus, Raptor 3D CAD/CAM Software takes CNC innovation further by enabling users to program faster and more accurately. Inspect, modify and export part information directly within the 3D platform. This coupled with Peddinghaus CNC technology means maximum capacity for fabricators.

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.