Machine Information

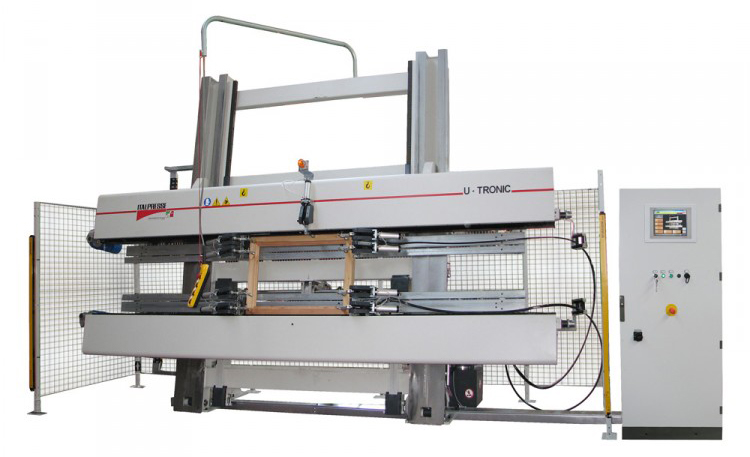

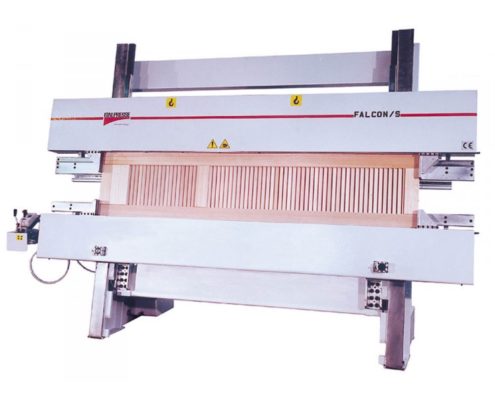

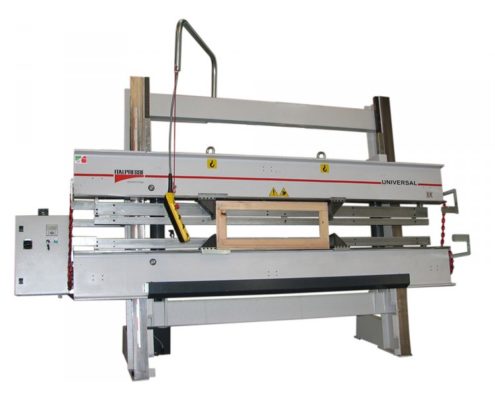

SDE, NUOVO PROGRAM, FALCON/S, UNIVERSAL, UNIVERSAL/CN, U-TRONIC

Italpresse is proud to introduce the next generation of door and window frame clamps. The new designs are a synergy between Italpresse’s 50 years of engineering and manufacturing expertise and valuable input gained from woodworkers who use these machines everyday. Recent technological advancements in the window and door industries have generated demand for assembly clamps with precise positioning control and low clamping pressures. Italpresse has responded to this demand with the introduction of new innovative solutions, some of which are now patented. Great attention has been paid to the design to enhance the rigidity of the frame and precision of the clamping and squaring action even for the most challenging joinery techniques. An in depth ergonomic study combined with input from the people who use these machines everyday has raised the standards to a new level making the clamps easier and faster to work with while reducing operator fatigue. The complete range of frame clamps offered by Italpresse has been designed for both traditional and new innovative joinery techniques. More and more of our customers are moving towards pre-squared and finished windows frames or the use of mechanical fasteners. In many cases, our customers must utilize various joinery techniques in their production of frames requiring a broad range of control capability from the frame clamp. Our latest generation of clamps provides this level of control and more.