Videos

Machine Information

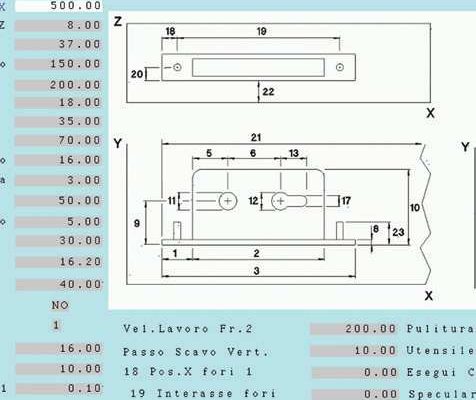

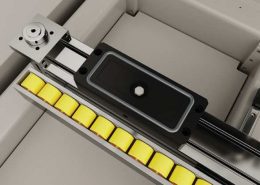

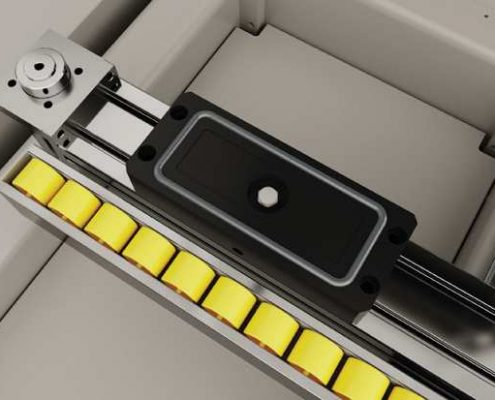

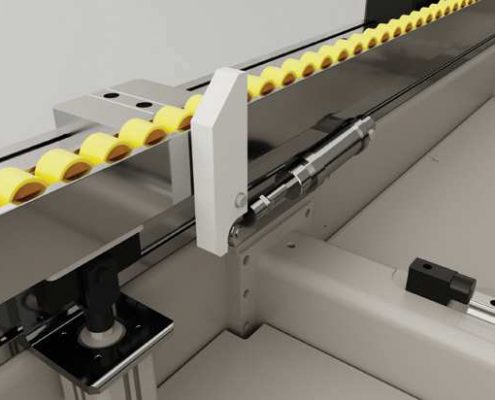

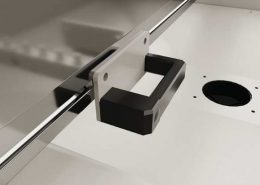

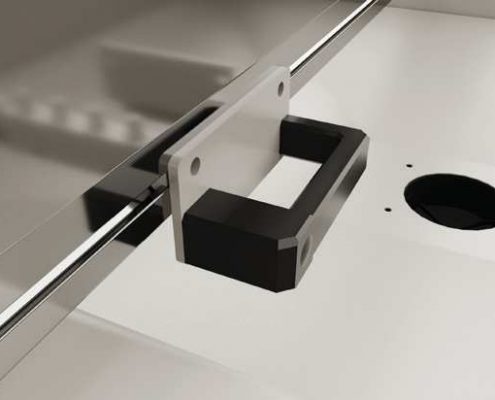

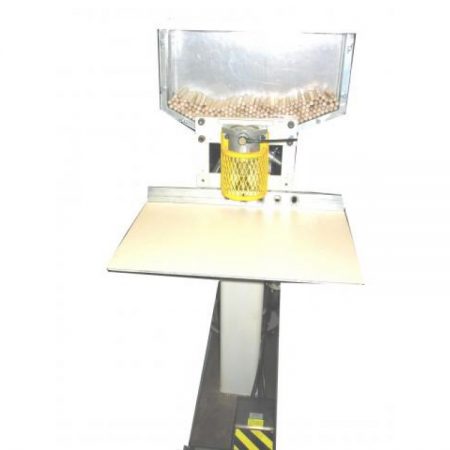

A versatile and flexible double sided NC controlled machining centre suitable for a variety of door machining operations. The simple vaccum system hold the door in position for easy access to all type of machining such as hinge recessing, lock slots, handle holes, key slots and euro grooves etc. Programming is extremely simple thanks to the colour graphic touch screen controller using pre-installed electronic macros. The standard machine is equipped with two milling heads either side of door position, the lock side will automatically position both vertically for handle / key holes and horizontally for lock case / faceplate. Optional additional machining operations include producing a square corner hinge plate recess or lock face recess by means of the additional milling units – using 3mm drill. The operator simply selects in the program if they want a radius or square corner and the machine does the rest. In addition the same milling heads can be used to make the small pilot hole for hinge screws etc.

The machine is suitable for machining frame material for all work through a set of interchangable clamps.

![centauro[1]](https://www.akhurst.com/wp/wp-content/uploads/2018/01/centauro1.jpg)